Waterproof, moisture-conductive shoes

A technology of water layer and wet layer, applied in the direction of shoe uppers, shoes, soles, etc., can solve the problems of complex manufacturing process, breeding bacteria, high cost, etc., and achieve the effect of simple structure, easy processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

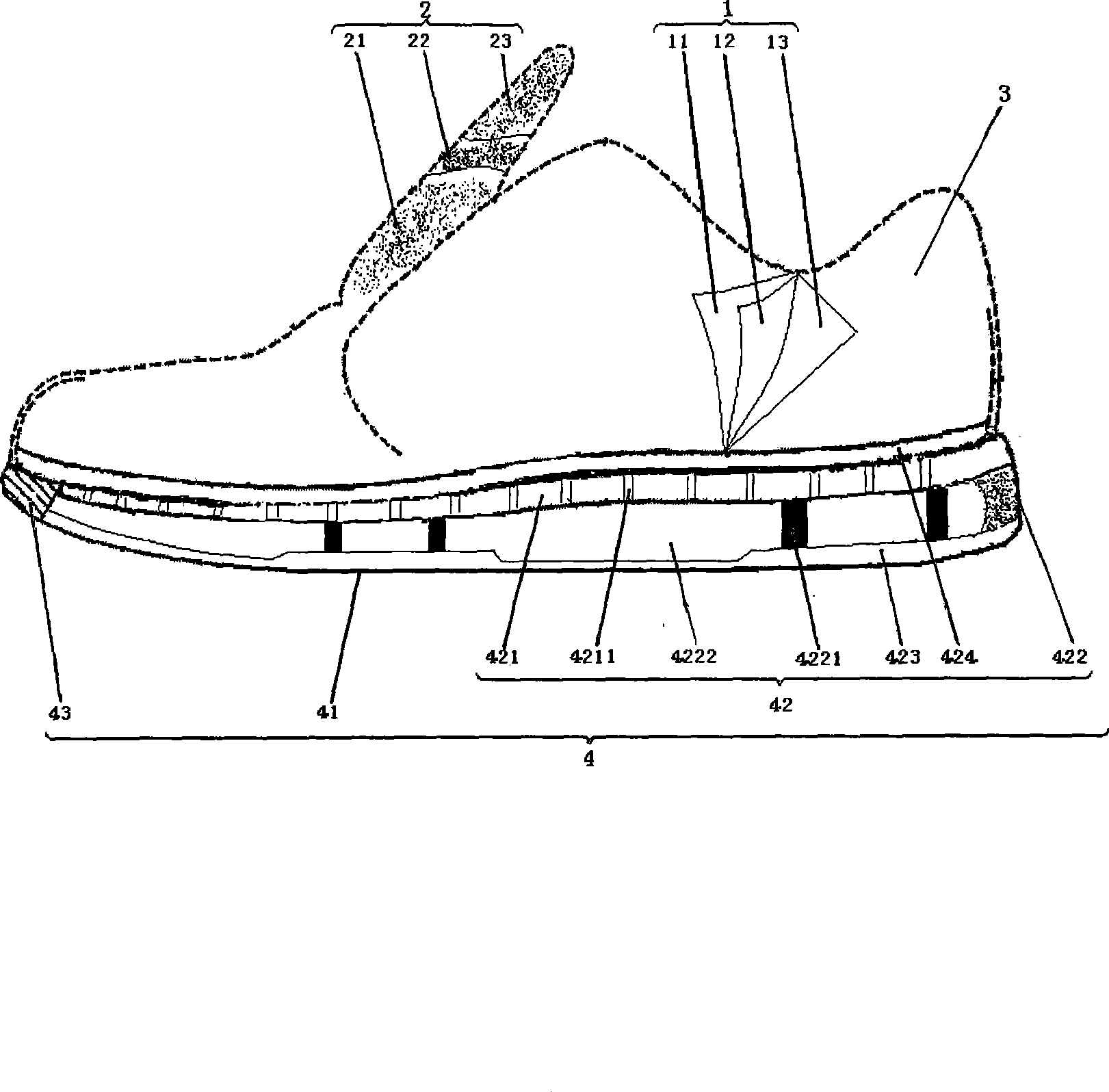

[0018] Referring to the accompanying drawings, the waterproof and moisture-wicking shoes of the present invention include a sole 4 , an upper 3 combined with the sole 4 , a vamp 1 combined with the sole 4 , and a tongue 2 extended on the vamp 1 . The material of the shoe upper 1 is a laminated unidirectional moisture-conducting fabric composed of three layers, and the three layers of the laminated unidirectional moisture-conducting fabric are sequentially from the inside to the outside: the first water-repellent layer 11, the first connecting layer 12 and the first moisture-conducting layer 13, the material of the first moisture-conducting layer 13 adopts a weft-knitted double-sided fabric of combed cotton fiber yarn, and the material of the first water-repellent layer 11 adopts combed cotton fiber yarn Weft-knitted double-sided fabric, and the upper and lower surfaces of the first water-repellent layer 11 are preferably coated with a waterproof agent for cotton of the model 11...

Embodiment 2

[0020] The figure is omitted, only the first and second moisture-conducting layers 13 and 23 are made of wool fiber; the first and second connecting layers 12 and 22 are made of polyurethane film; the first and second water-repellent layers 11 and 21 The material adopts wool fiber; the material of the midsole 42 adopts synthetic rubber. All the other are the same as the description of embodiment 1. Example 3:

Embodiment 3

[0021] The figure is omitted, the material of the first and second moisture-conducting layers 13 and 23 is silk fiber; the material of the first and second connecting layers 12 and 22 is polyurethane film; the first and second water-repellent layers 11 and 21 The material of the material adopts silk fiber; The material of the midsole 42 adopts EVA (ethylene vinyl acetate copolymer). All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com