Welt-process three-turn smoke-prevention, dust-control gas-purification device

A technology for smoke elimination, dust removal, and gas purification, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problem of low chemical consumption, achieve low energy and chemical consumption, wide applicability, and no deposits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

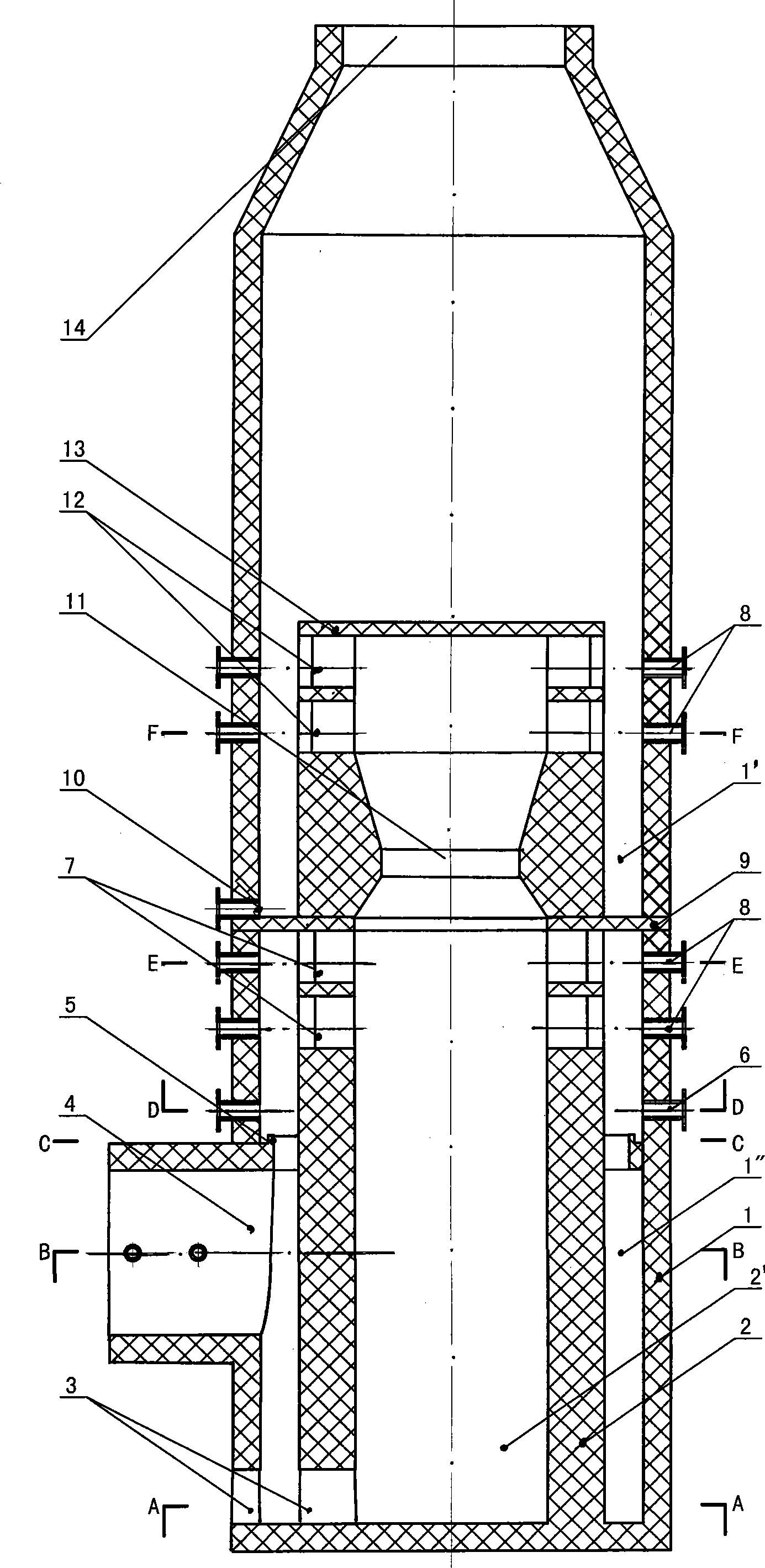

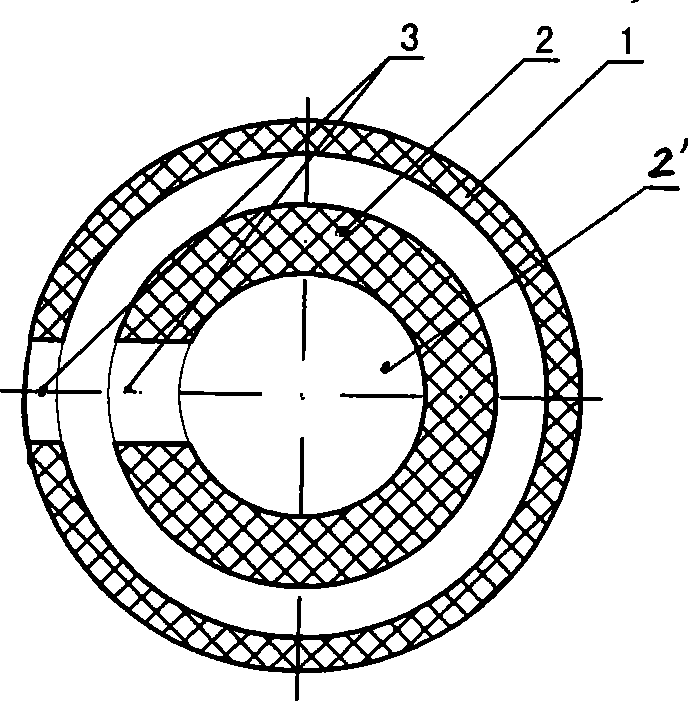

[0013] Embodiment 1, the wet three-rotation smoke elimination and dust removal device of the present embodiment, its structure can be from figure 1 , figure 2 with image 3 As can be seen in the figure, it includes a clean gas outlet pipe 14 at the top, a tangential exhaust gas inlet pipe 4 at the bottom, an outlet pipe 3 for gray water and ash residue, and a tangential medicinal liquid nozzle provided on the side wall. The main tower 1 of circular cross-section of 6, coaxially installs an inner tower 2 with top plate 13 and central tunnel 2' in the main tower; Make the circular cylindrical space between the main tower and the inner tower be divided into an upper space 1 ' and a lower space 1 " that do not communicate with each other. The gray water and ash in the upper space 1' are discharged from the outlet pipe 10 of the upper space outside the main tower, and a set of outlets for exhaust gas to enter the inner tower from the lower space 1" of the main tower are provided...

Embodiment 2

[0017] Embodiment 2, the wet three-rotation smoke elimination and dust removal device of the present embodiment, its structure can be from figure 1 It can be seen in the figure that the difference from Example 1 is that its inner tower 2 is arranged as a Venturi tube 11 on the wall surface of the central channel 2' above the tangential inlet 7, that is, the inner diameter of the central channel 2' is from From bottom to top, it first shrinks and then expands, and there is a small section of equal diameter between the shrinking section and the expanding section. Through the Venturi tube 11, the gas-liquid mixing swirl flow entering the inner tower 2 central channel 2' from the tangential inlet 7 can be further accelerated, thereby enhancing the effect of the clean gas reaction and dust removal.

Embodiment 3

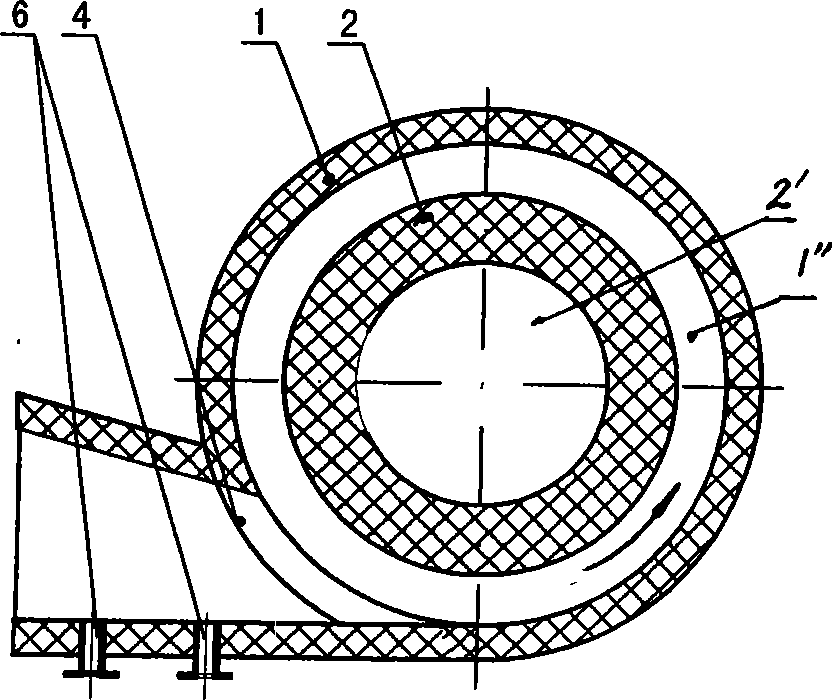

[0018] Embodiment 3, the wet three-rotation smoke elimination and dust removal device of the present embodiment, its structure can be from figure 1 and Figure 4 It can be seen in that, the difference from embodiment 1 or embodiment 2 is that its chemical liquid spray pipe 6 is arranged on the inner wall of the main tower above the waste gas inlet pipe 4, and between the chemical liquid spray pipe 6 and the waste gas inlet pipe 4 The inner wall of the main tower between is provided with a full circle of overflow tank 5 for the overflow of medicinal liquid. The overflow tank can accumulate the liquid medicine down the inner wall of the main tower, and when it is full, it will overflow from the top of the overflow tank; thus expanding the contact probability of the waste gas entering the tower and the liquid medicine, The gas-liquid mixing effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com