Bored pile control method, control system and drill using the control system

A control system and control method technology, applied to the automatic control system of drilling, drilling equipment and methods, sheet pile walls, etc., can solve the problems of deviation of measurement results, failure of CFG drilling rigs to provide effective prompts, and influence on construction quality, etc., to achieve The effect of high accuracy, reducing the number of construction personnel and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

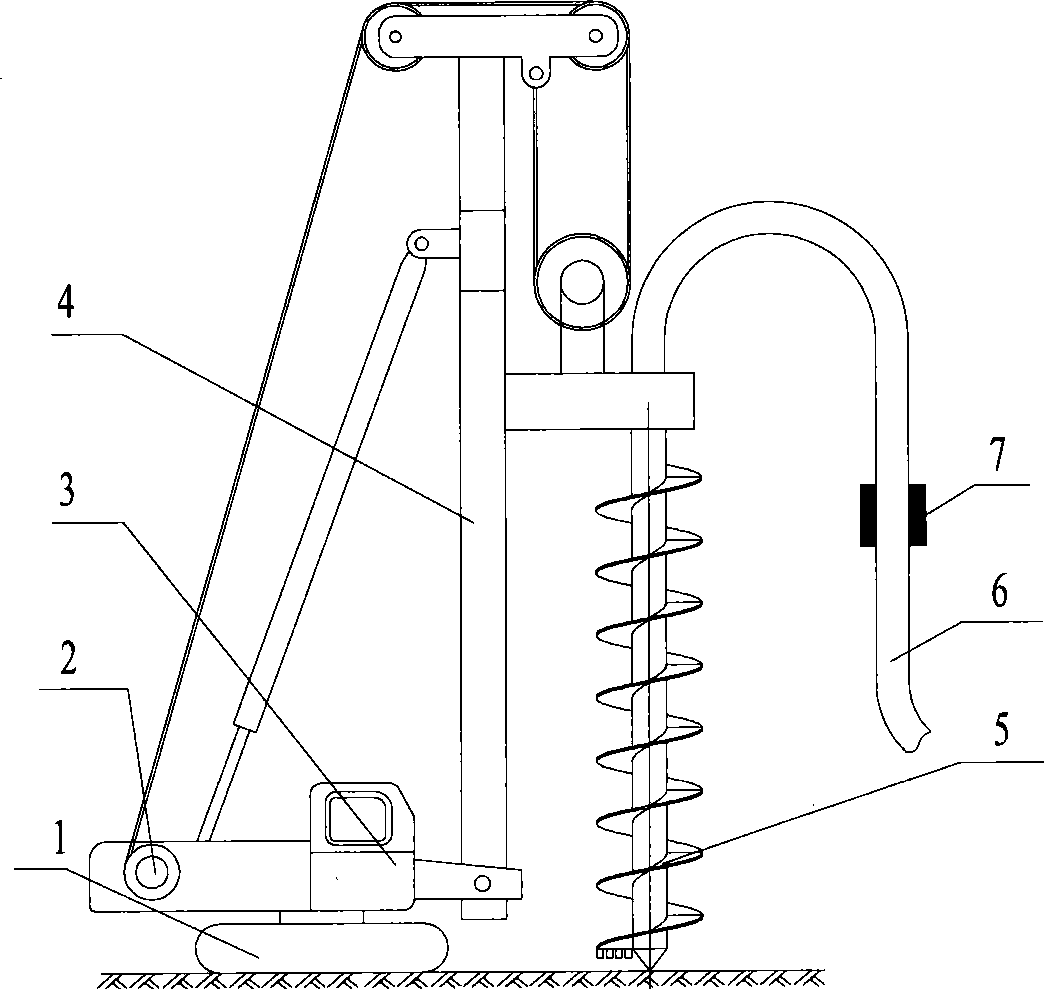

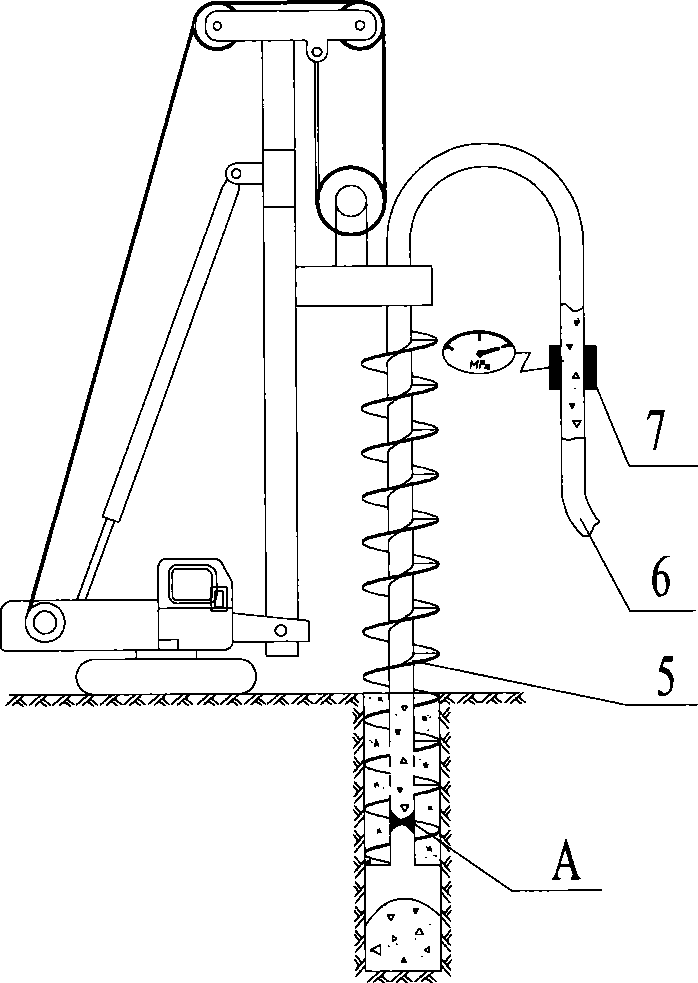

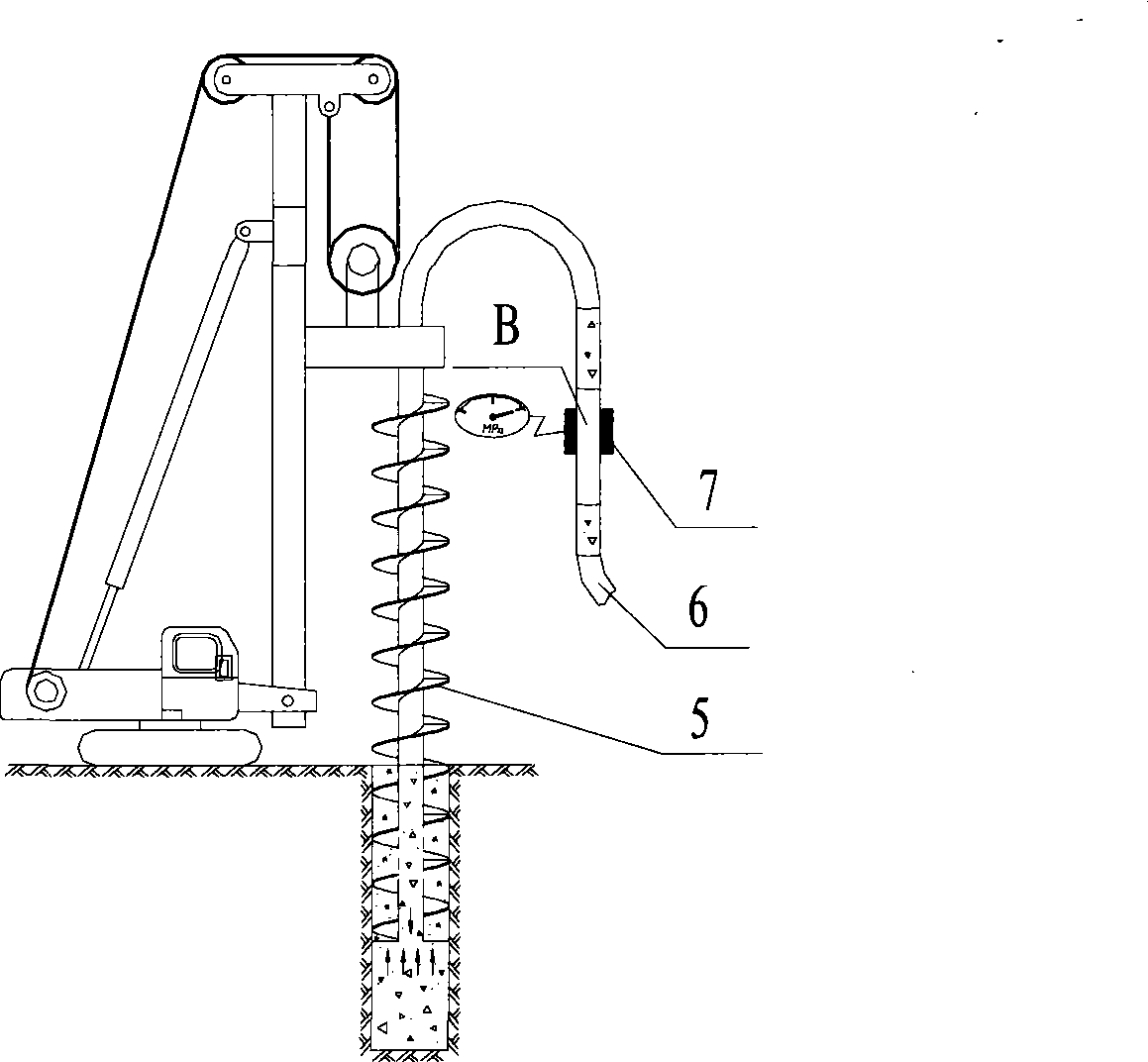

[0059] The basic idea of the present invention is to automatically control the drilling and pulling back of the drill pipe; obtain reliable mud pressure at the bottom of the drill pipe by detecting the pull force of the main winch, obtain the mud pressure deviation at the bottom of the drill pipe and control it as the control object, and realize The drill pipe is pulled back at the expected speed, and an appropriate and stable pressure is maintained at the concrete outlet at the bottom of the drill pipe.

[0060] For the convenience of describing the present invention, relevant terms are explained as follows:

[0061] PID control, that is, proportional, integral, differential control, also known as PID regulation. Among them, P represents the proportional gain, the proportional adjustment setting is large, and when the system deviates, the adjustment can be accelerated to reduce the error, but too large proportional gain will cause the system to be unstable; I represents the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com