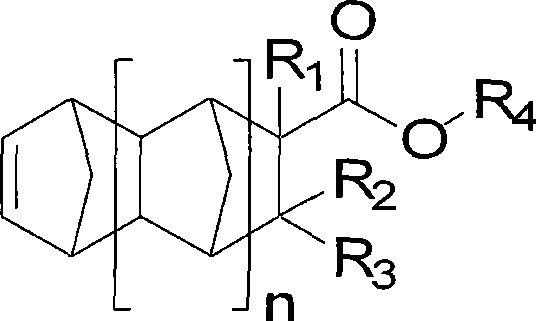

Norbornene-ester polymer containing bulky substituents

A norbornene and polymer technology, applied in the field of norbornene-ester polymers, can solve problems such as difficult to ensure and unsuitable, and achieve the effects of improving light transmittance, good metal adhesion, and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] The present invention can be better understood through the following examples, which are set forth for illustration and should not be construed as limiting the present invention.

[0054] Synthesis of Norbornene-Ester Monomer (Synthesis Examples 1-8, Comparative Synthesis Examples 1-2)

Synthetic example 1

[0055] Synthesis of 2-methyl-2-adamantyl-5-norbornene-2-methyl-2-carboxylate

[0056] Into a 0.25 L autoclave, DCPD (dicyclopentadiene, Aldrich, 10.2 ml, 0.0757 mol), 2-methyl-2-adamantyl methacrylate (42.6 g, 0.18 mol) and hydroquinone ( 0.83g, 0.1mol), then it was reacted at 180°C for 12 hours, after the reaction product was cooled, it was transferred to a distillation apparatus, and then a vacuum pump was used to distill under a reduced pressure of 1 torr, thereby obtaining the final product at 110°C (product rate: 25%). The molar ratio (mol%) of exo isomer to endoisomer of this product was 48.5:51.5.

[0057] 1 H-NMR (500MHz, CDCl 3 ), inner shape: δ 6.20(dd, 1H), 6.18(dd, 1H); outer shape: δ 6.12(m, 2H)

Synthetic example 2

[0058] Synthesis of 2-ethyl-2-adamantyl-5-norbornene-2-methyl-2-carboxylate

[0059] Into a 0.25 L autoclave, DCPD (dicyclopentadiene, Aldrich, 10.2 ml, 0.0757 mol), 2-ethyl-2-adamantyl methacrylate (44.3 g, 0.18 mol) and hydroquinone ( 0.83g, 0.1mol), then it was reacted at 200°C for 12 hours, after the reaction product was cooled, it was transferred to a distillation apparatus, and then a vacuum pump was used to distill under a reduced pressure of 1 torr, thereby obtaining the final product (product) at 120°C rate: 27%). The molar ratio (mol%) of exo isomer to endo isomer of this product is 45.5:54.2.

[0060] 1 H-NMR (500MHz, CDCl 3 ), inner shape: δ 6.22(dd, 1H), 6.19(dd, 1H); outer shape: δ 6.18(m, 2H)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com