Motor rotor position sensor and method for measuring position of motor rotor

A technology of motor rotor and sensor, applied in the direction of converting sensor output, measuring device, using electromagnetic/magnetic device to transmit sensing components, etc., can solve the problem of low measurement accuracy, eliminate distance changes and temperature changes, low cost, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

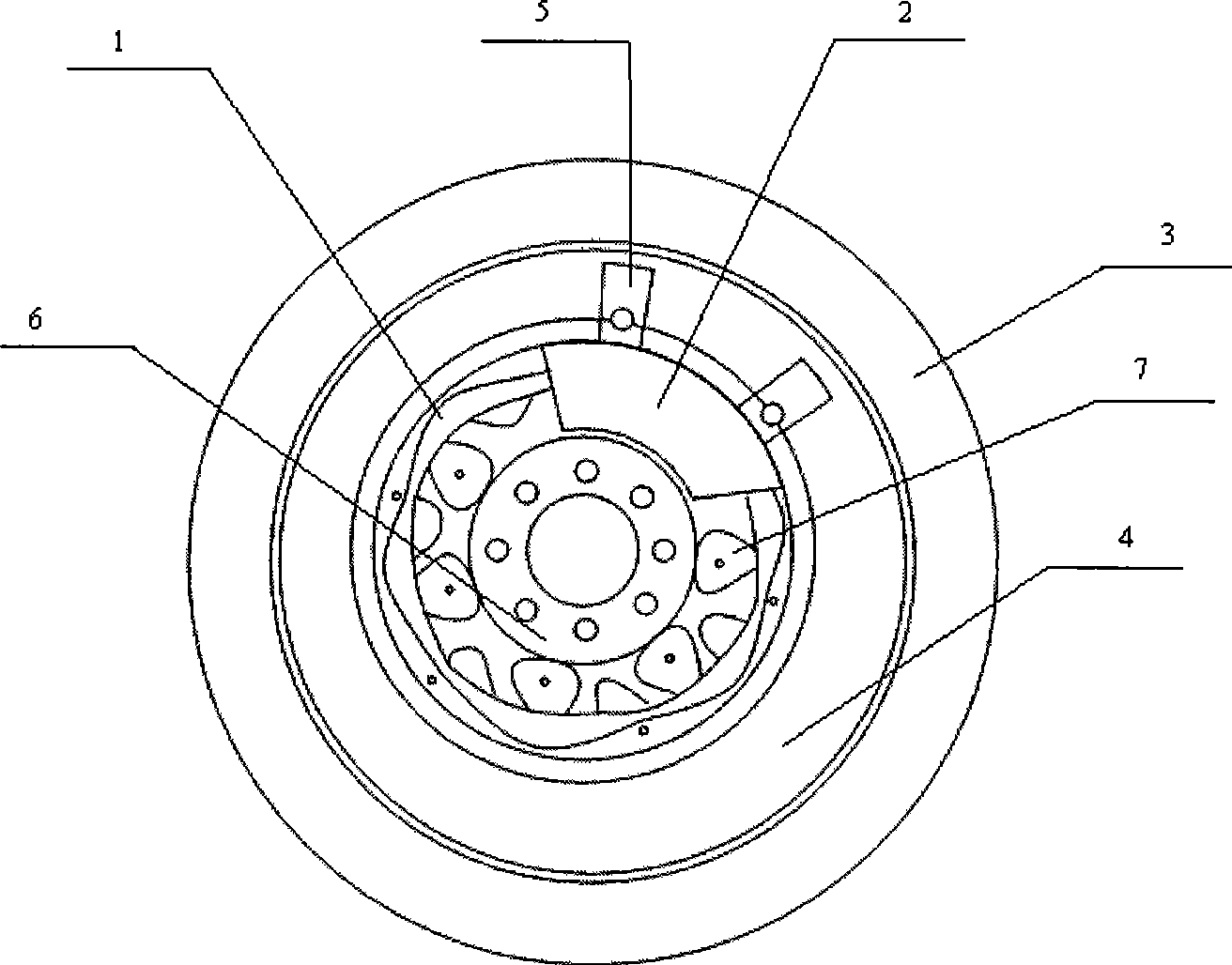

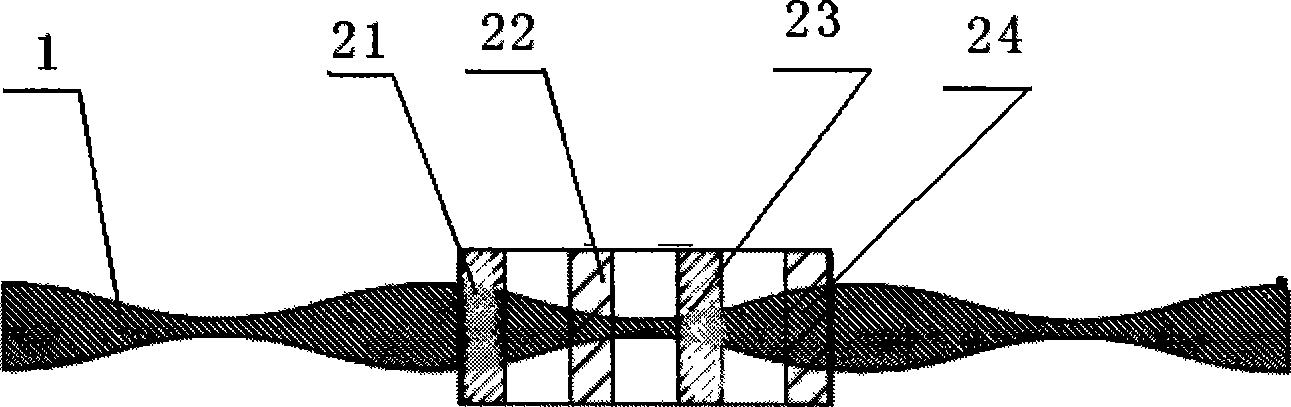

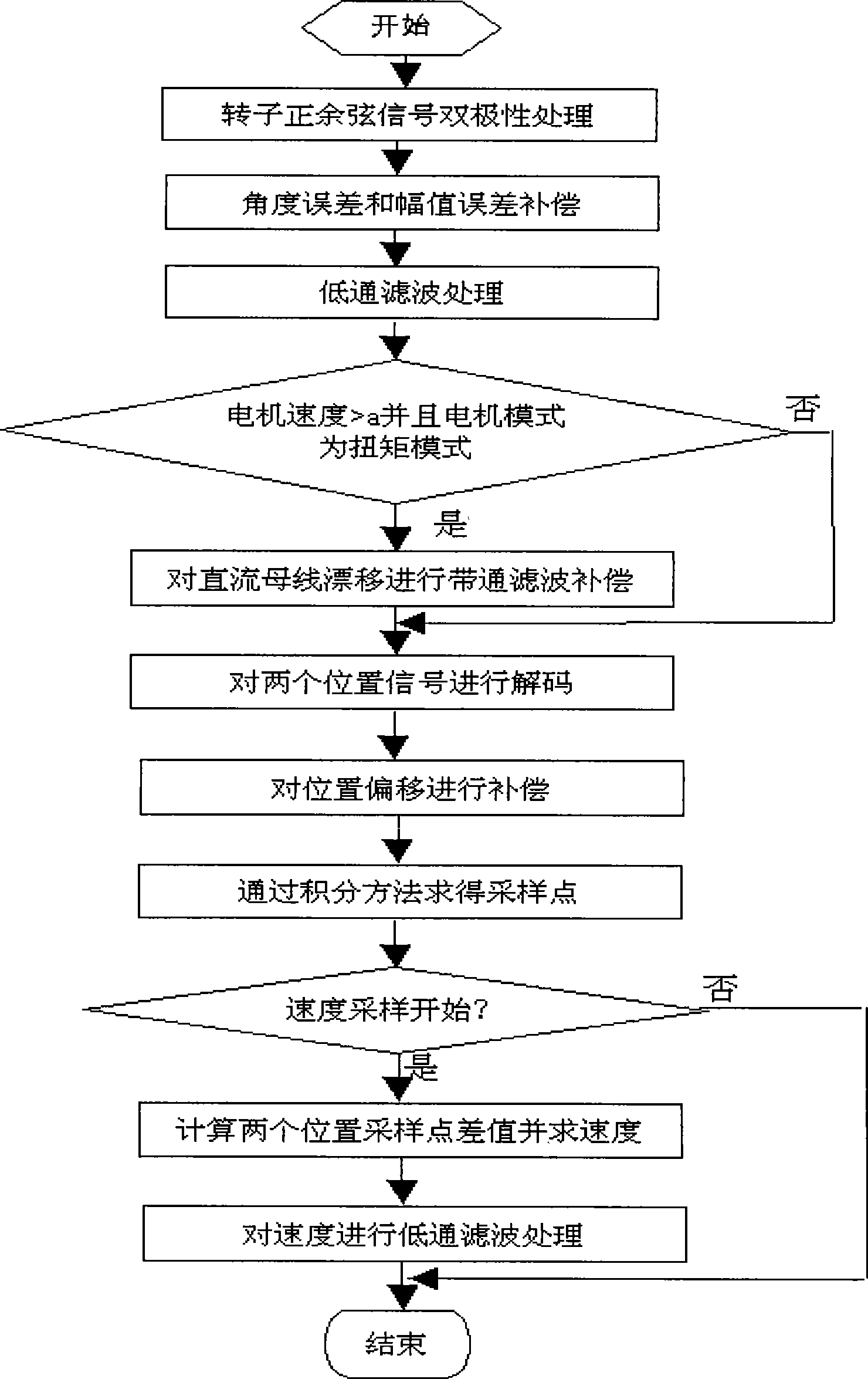

[0025] like figure 1 It is a schematic diagram of the installation of the rotor position sensor in an embodiment of the present invention, as shown in the figure: the rotor position sensor of the present invention includes an inductor 2 and a target disk 1, which are installed at one end of the motor, and the target disk 1 is an annular disk, which is The shape of the outer pattern is a sine curve or a cosine curve, and is made of metal materials such as aluminum or iron. It is installed and fixed on the rotor 4 bracket 7 and rotates around the rotor bracket axis 6 together with the rotor 4. The sensor 2 is installed through the sensor mounting bracket 5 On one side of the stator 3, the inductor 2 includes a planar winding and an ASIC (Application Specific Integrated Circuit) that processes the signals induced by the planar winding. The ASIC circuit is designed, manufactured and commercialized by Chery Automobile Company. The output is connected to TMS320f2808 DSP chip.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com