Rail tread defect rapid scanning and detecting method and device thereof

A technology for scanning devices and rails, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve the problems of slow detection speed and difficulty in detection, and achieve long detection distance, simple structure, and environmental adaptation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

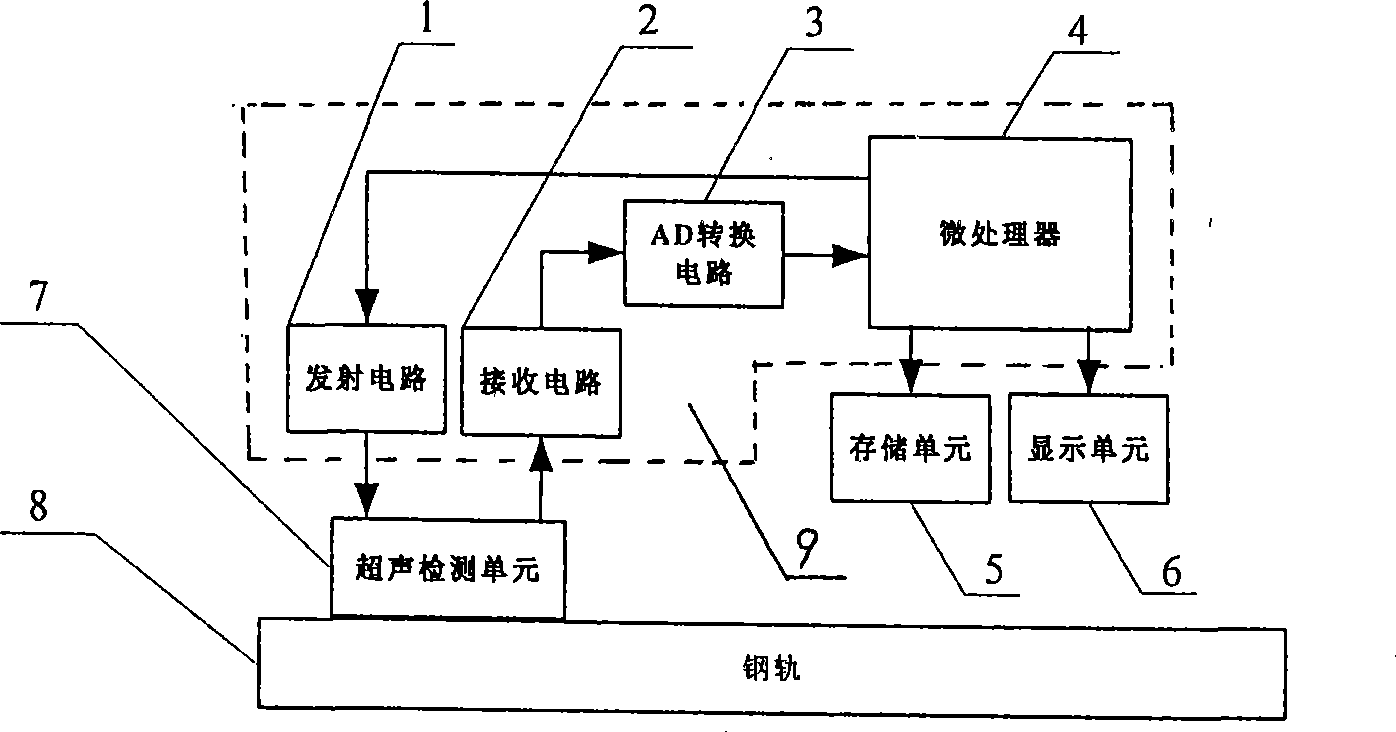

[0036] Embodiment 1, combining figure 1 , the present invention is a rapid scanning device for rail tread defects, which is composed of an ultrasonic detection unit (7), a circuit system (9), a storage unit (5) and a display unit (6). The ultrasonic detection unit (7) is connected to the circuit system (9), and the circuit system (9) is respectively connected to the storage unit (5) and the display unit (6). The circuit system (9) includes a transmitting circuit (1), a receiving circuit (2), an AD conversion circuit (3) and a microprocessor (4). The transmitting circuit (1) is connected to the microprocessor (4), the microprocessor (4) is connected to the AD conversion circuit (3), and the AD conversion circuit (3) is connected to the receiving circuit (2). The ultrasonic detection unit 7 is composed of an ultrasonic probe A and an ultrasonic probe B, and the ultrasonic probe A and the ultrasonic probe B are arranged on the rail tread.

[0037] The present invention provides...

Embodiment 2

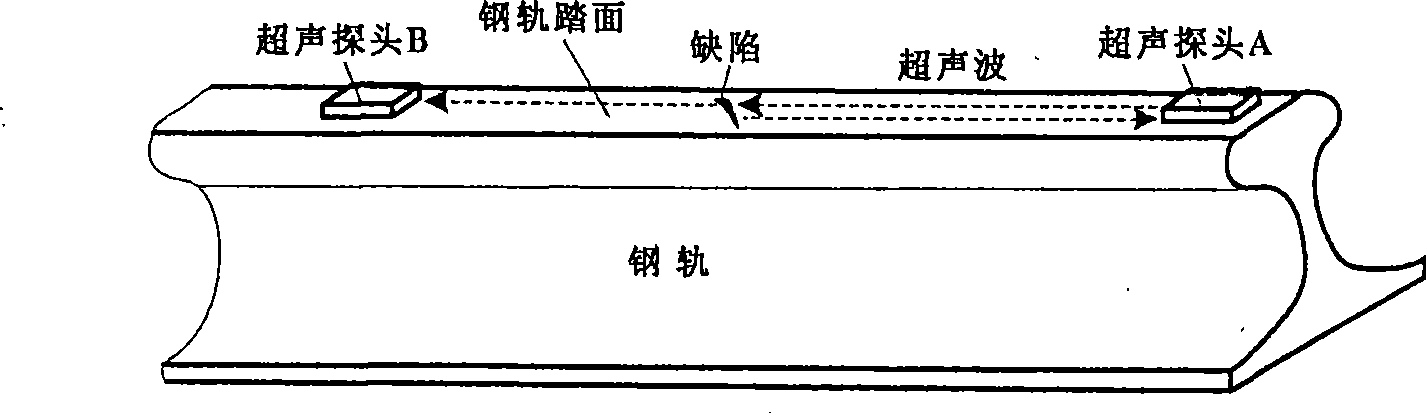

[0050] Example 2, combined with figure 2 , the ultrasonic detection unit (7) is composed of an ultrasonic probe A with a function of transmitting and receiving and an ultrasonic probe B with a receiving function, and has a function of sending and receiving twice. Among them, ultrasonic probe A is designed according to phased array technology, which can ensure that ultrasonic surface waves are emitted to one side, and avoid misjudgment of defect identification caused by ultrasonic waves emitted in two directions.

[0051] The working process of the detection device is as follows: the microprocessor (4) sends a control signal to the transmitting circuit (1), and the transmitting circuit (1) drives the ultrasonic probe A to emit ultrasonic surface waves. The ultrasonic surface wave propagates in the rail with a propagation speed of about 3000m / s, and will attenuate when it encounters a defect. Ultrasonic probe A receives reflected echoes, and ultrasonic probe B receives transmi...

Embodiment 3

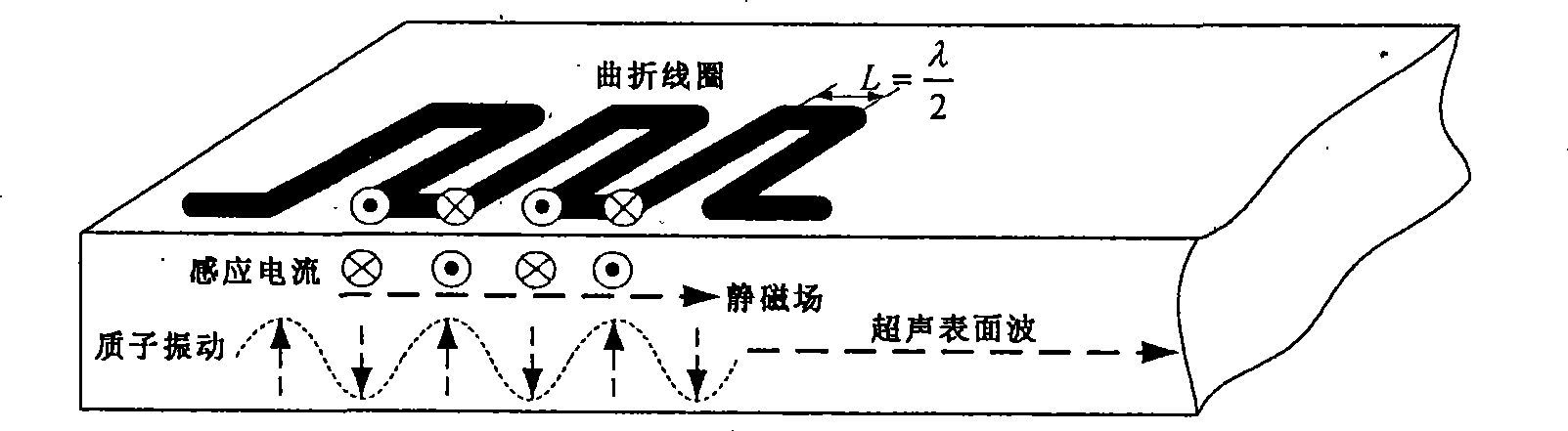

[0052] Example 3, combined with figure 2 , image 3 , The working principle of the ultrasonic surface wave described in the present invention is that the ultrasonic surface wave propagating along the surface of the measured object can be conveniently generated by using a special meandering coil. Such as figure 2 As shown, the ultrasonic transducer is placed on the rail tread, and the periodically transformed current is passed through the transmitting coil, and the tread can generate ultrasonic surface waves that propagate along the length of the rail; Attenuation occurs on the surface, and the position and size of the defect can be easily determined by measuring the time and intensity of the reflected echo and the attenuation degree of the transmitted wave. The propagation speed of ultrasonic surface wave in the rail is about 3000m / s, and the attenuation is small during the propagation process, which can realize the rapid scanning of rail tread defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com