Crystal particle reconfigure encapsulation method

A packaging method and reconfiguration technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of increasing the difficulty of cutting process and warping of the sealant, so as to save packaging materials and reduce packaging costs , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

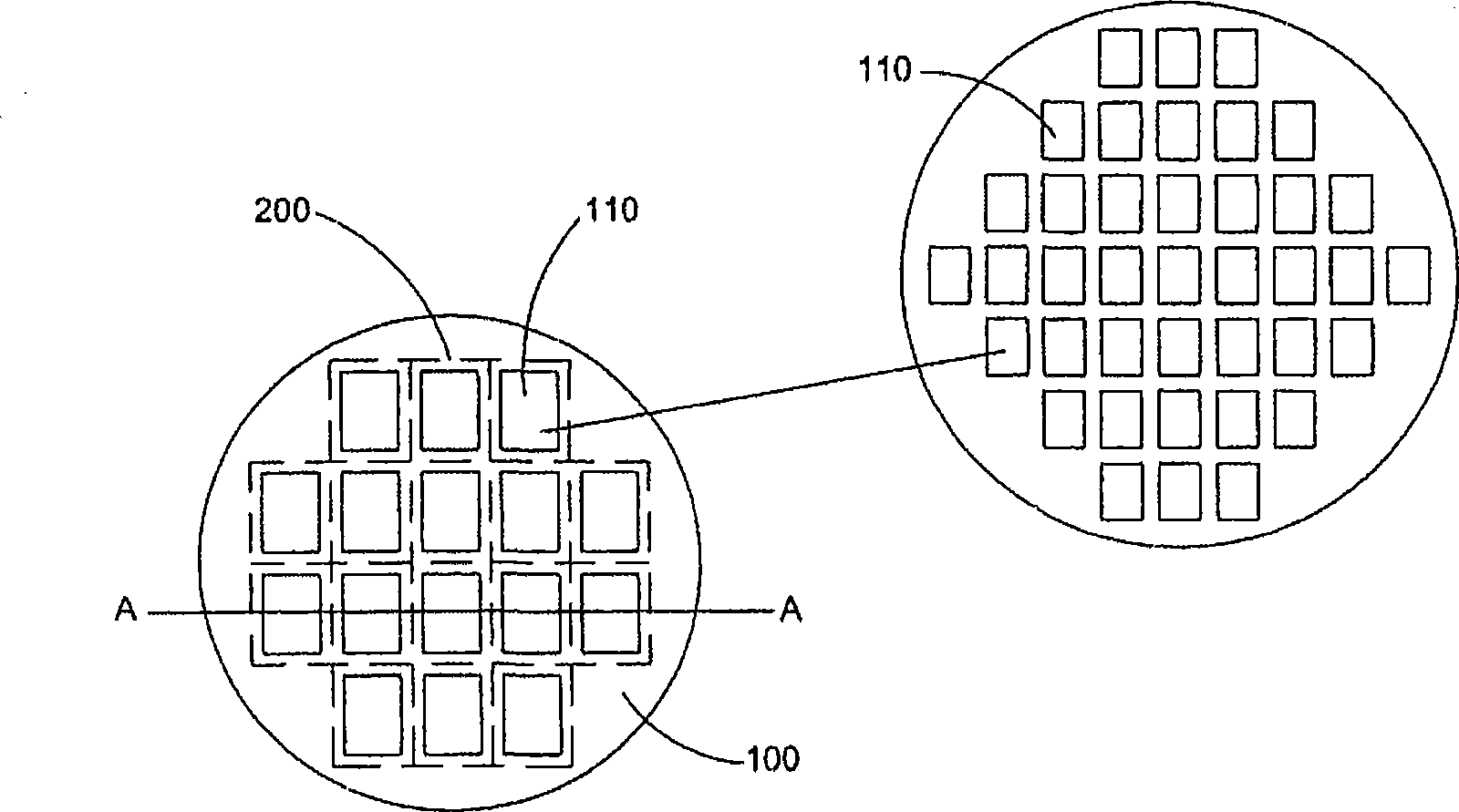

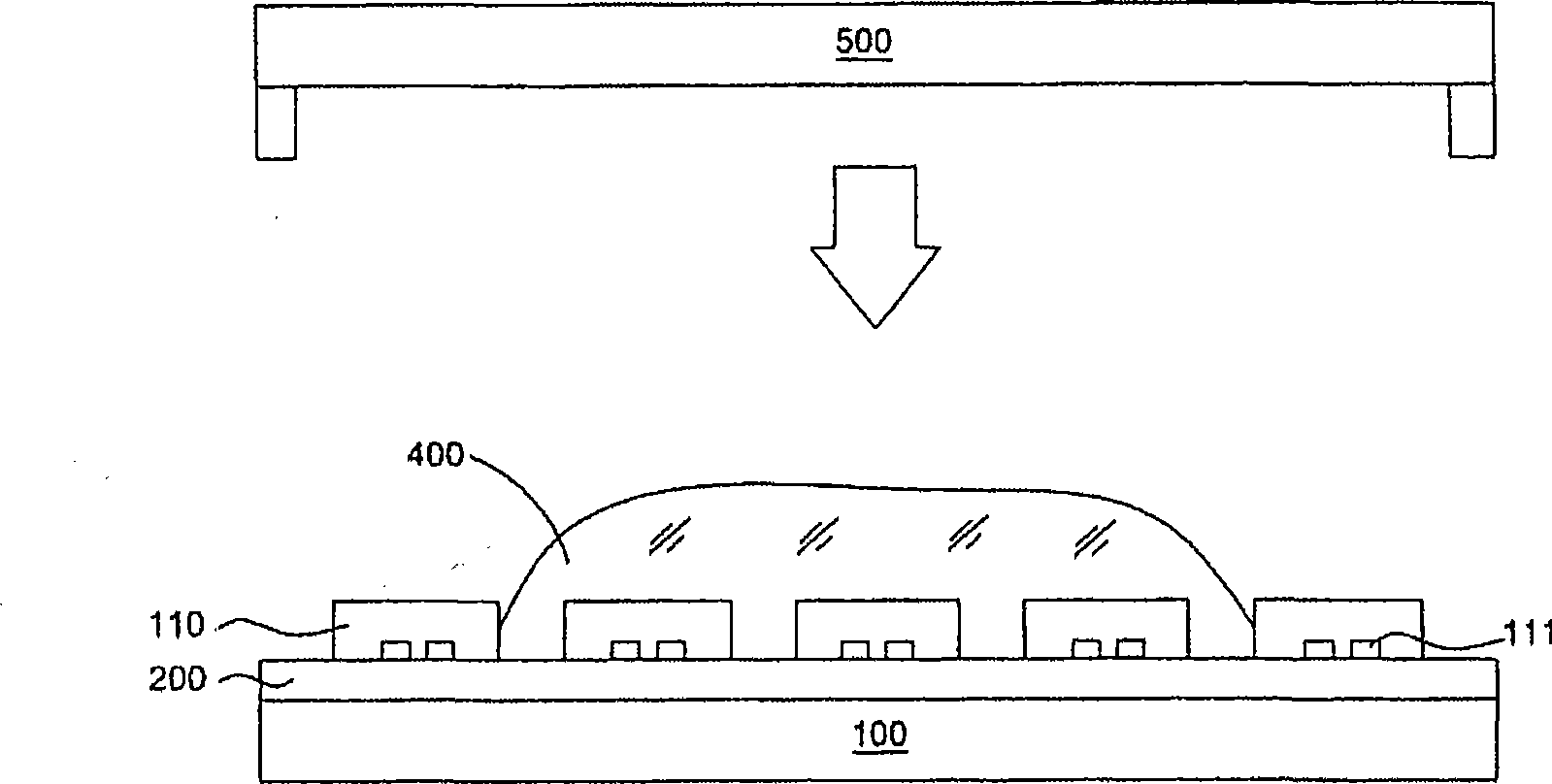

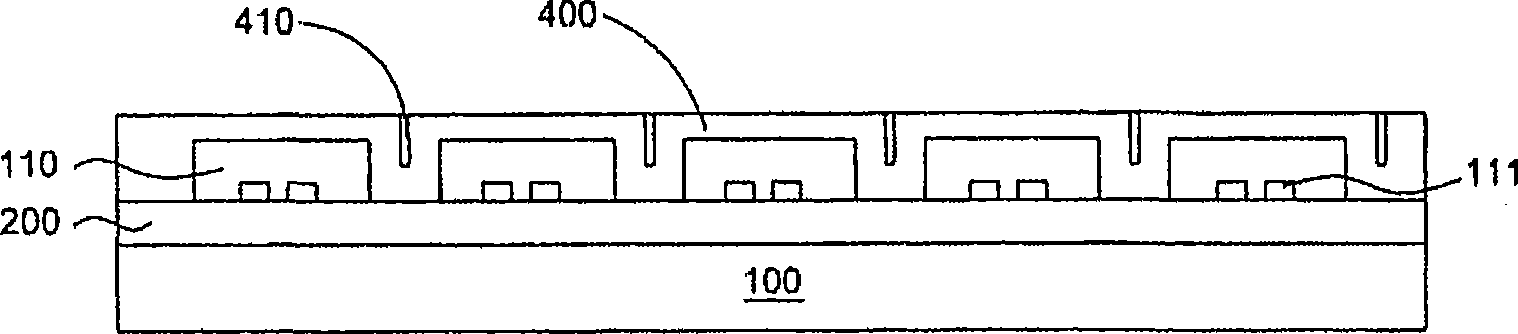

[0098] The direction of the present invention discussed here is a packaging method for reconfiguration of dies, in which a plurality of dies are redistributed on another substrate and then packaged. In order to provide a thorough understanding of the present invention, detailed steps and their components will be set forth in the following description. Obviously, the practice of the invention is not limited to specific details familiar to those skilled in the chip stacking scheme. On the other hand, well-known chip formation methods and detailed steps of back-end processes such as chip thinning are not described in detail to avoid unnecessary limitations of the present invention. However, for the preferred embodiments of the present invention, it will be described in detail as follows, but in addition to these detailed descriptions, the present invention can also be widely implemented in other embodiments, and the scope of the present invention is not limited. The scope of rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com