Patents

Literature

64results about How to "Save packaging material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

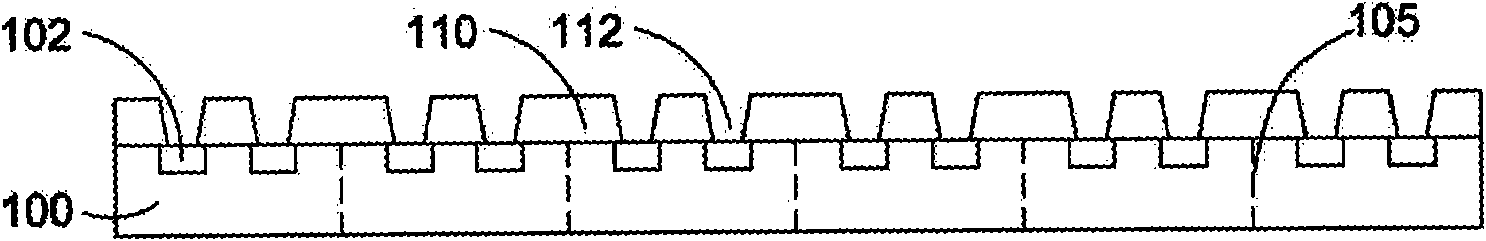

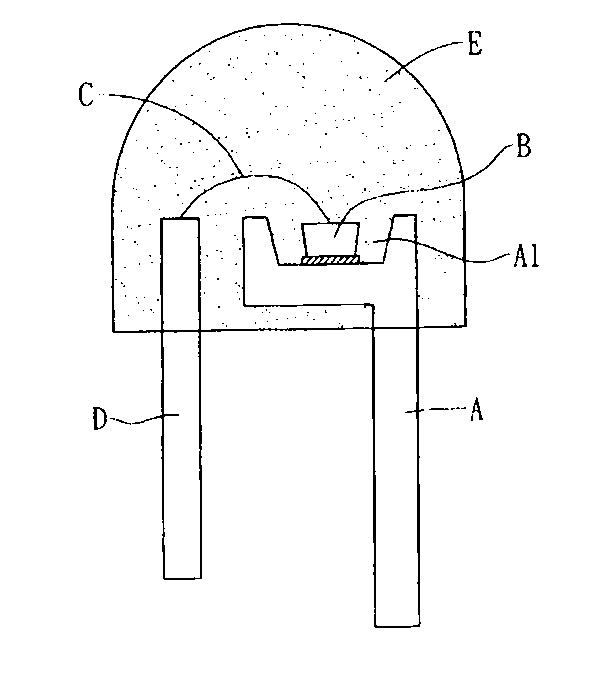

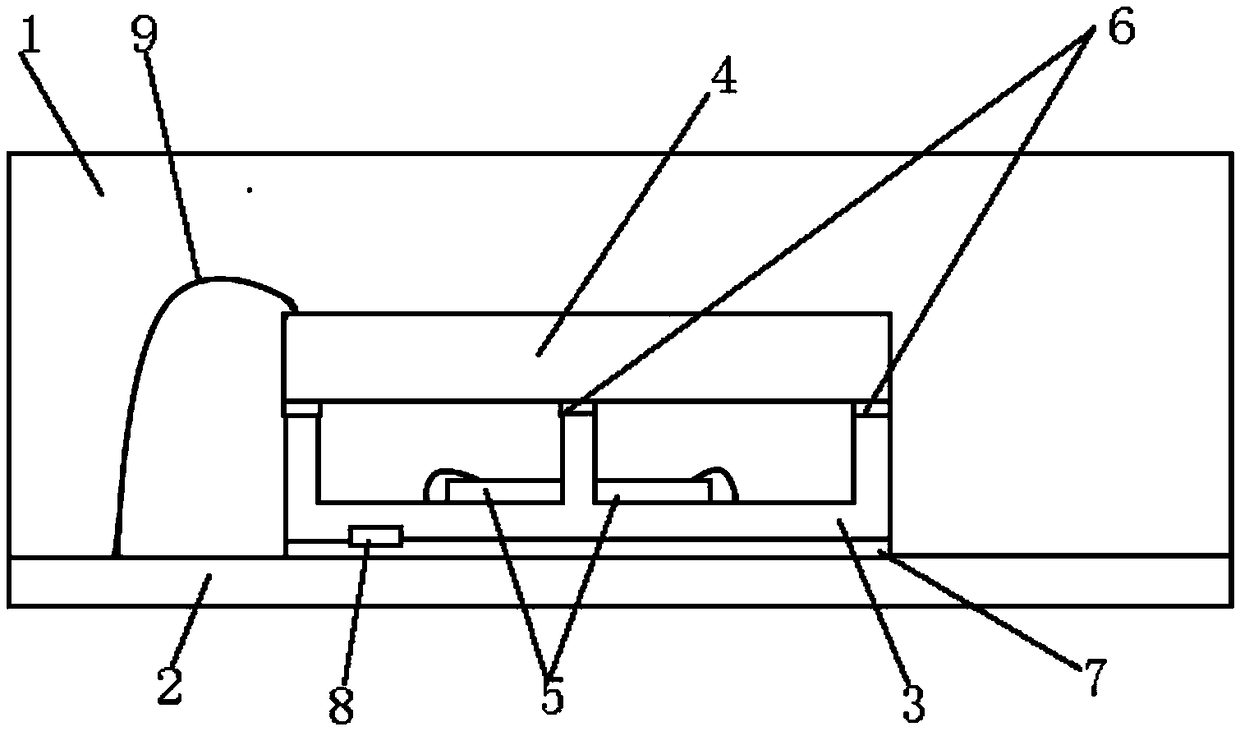

High-efficiency radiating LED illumination light source and manufacture method

InactiveCN101614333AImprove thermal conductivityPrecise thickness controlPoint-like light sourceElectric circuit arrangementsOptoelectronicsSilicon dioxide

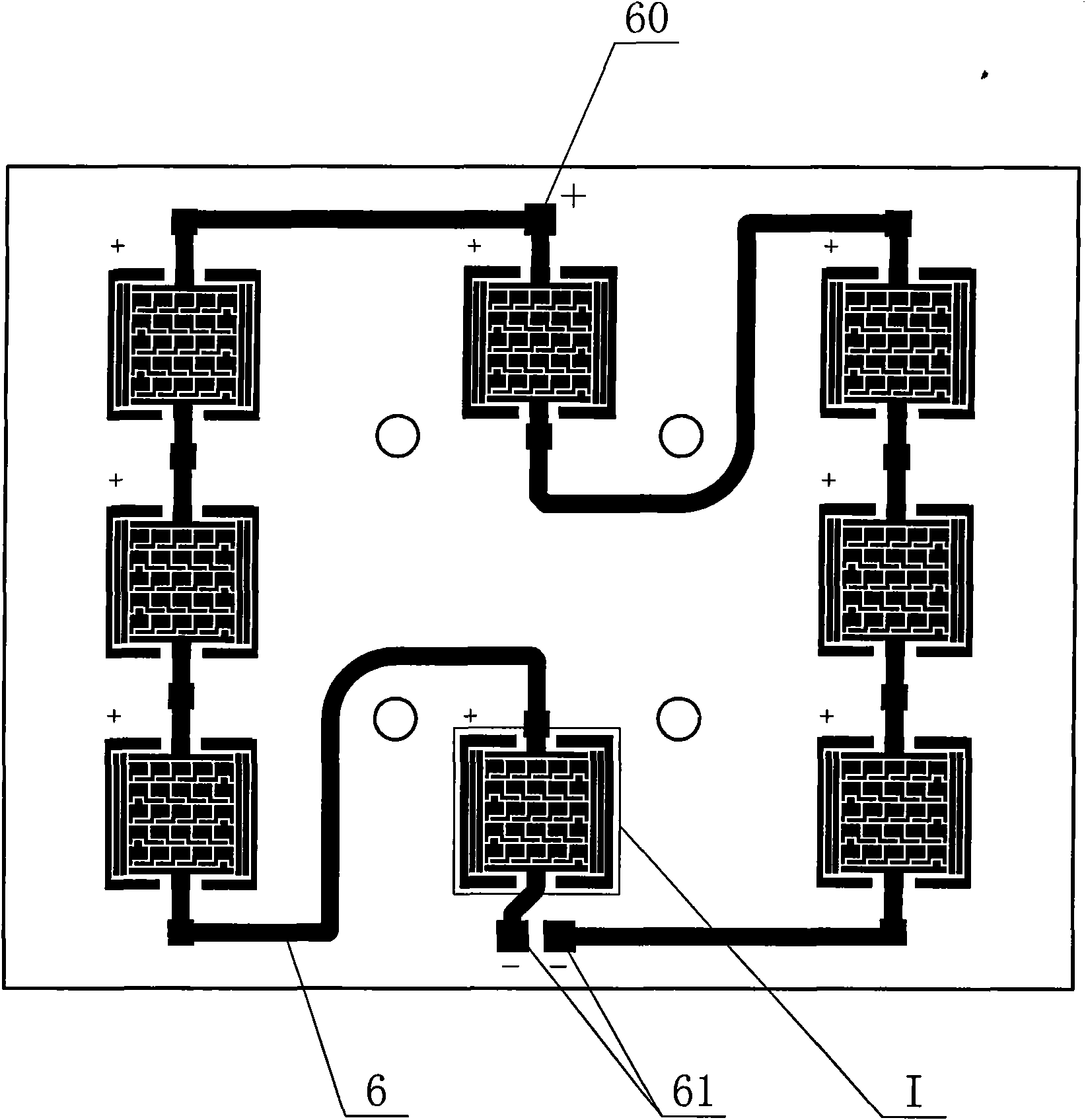

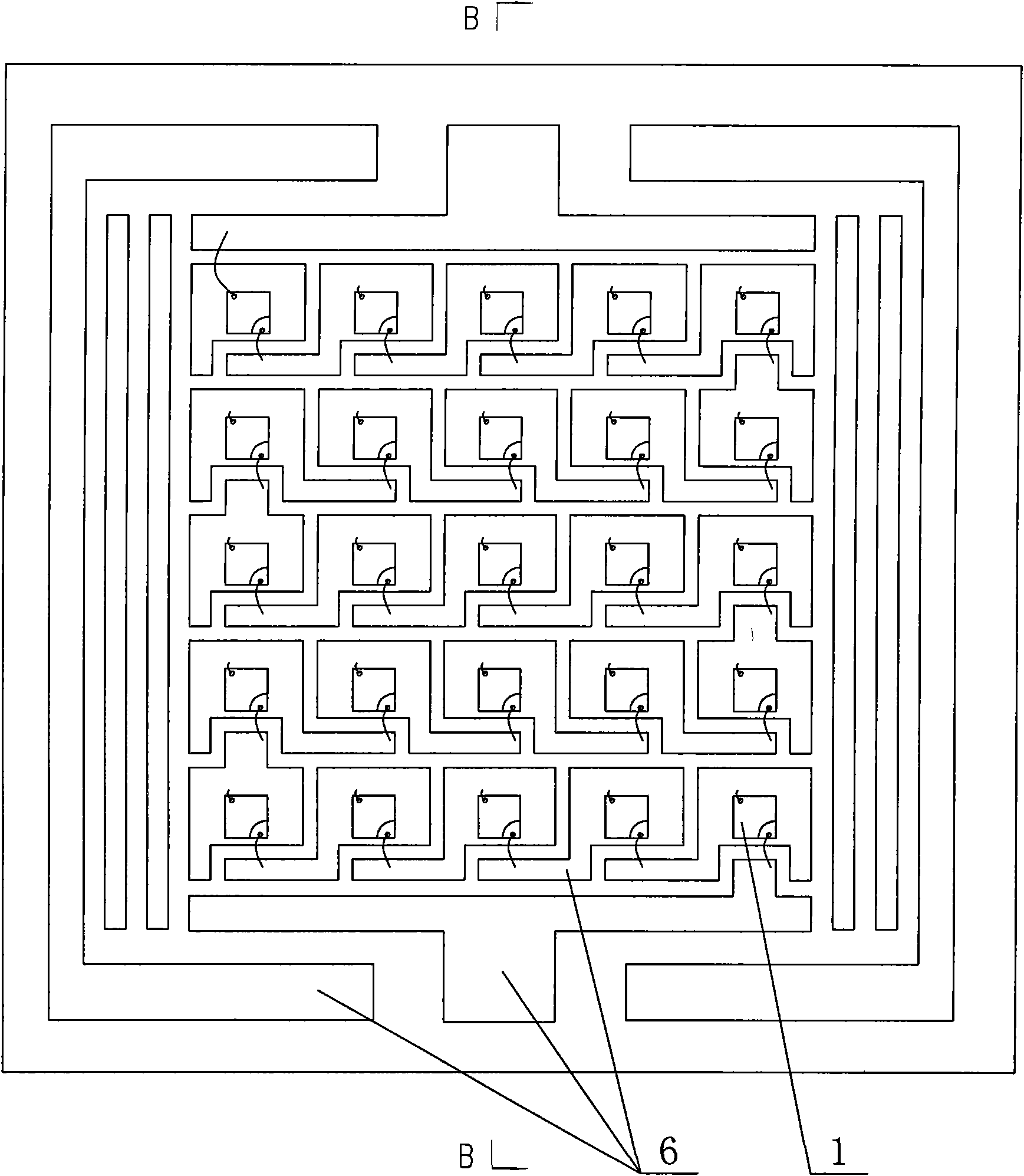

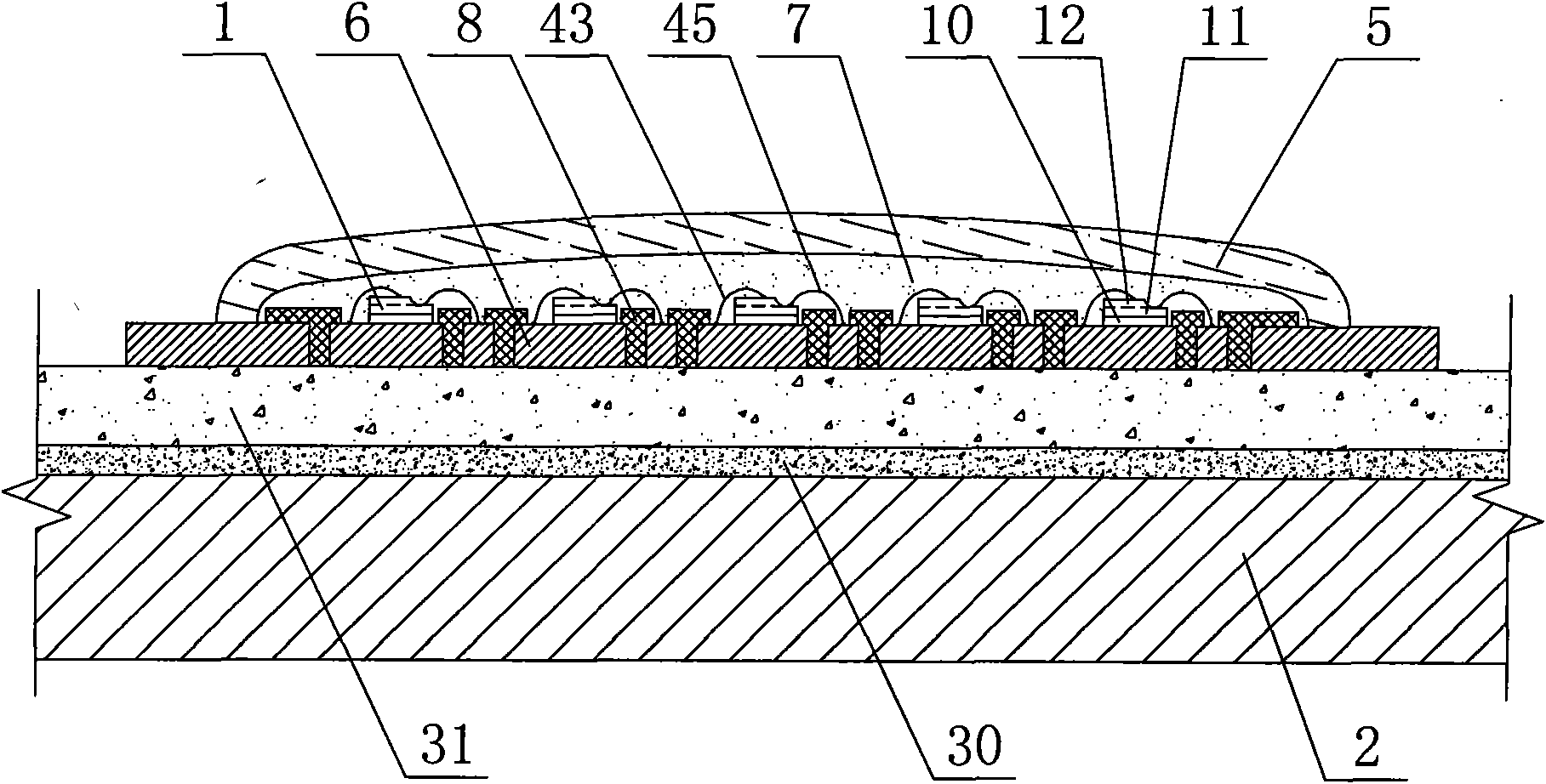

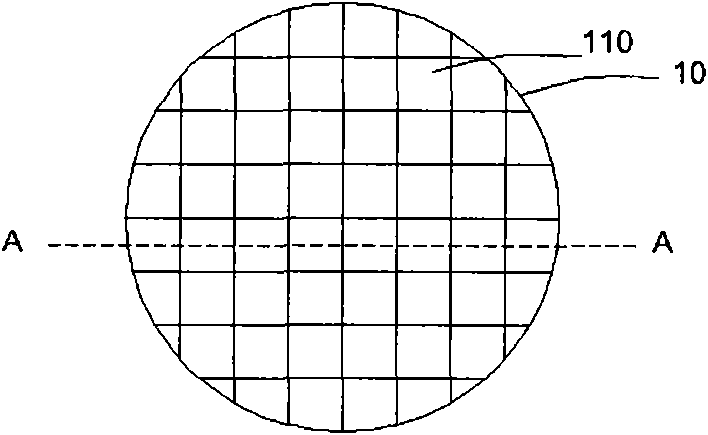

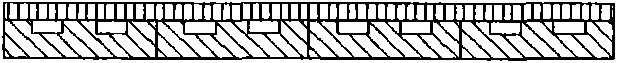

The invention discloses a high-efficiency radiating LED illumination light source with low cost, good radiating effect, high production efficiency and high manufacture precision and a manufacture method. The high-efficiency radiating LED illumination light source comprises LED bare chips (1) and a metal substrate (2), wherein a heat conduction insulating layer is deposited on the metal substrate (2); metal layers (6) are deposited on the heat conduction insulating layer; the metal layers (6)are covered by a welding prevention layer (8); the heat conduction insulating layer is combined by a silicon dioxide layer (30) or a silicon nitride (31) or the combination of the silicon dioxide layer (30) and the silicon nitride (31); a preset circuit connection and a preset figure are formed on each metal layer (6) according to the serial connection and parallel connection relation of the LED bare chip (1); the LED bare chips (1) are divided into a plurality of groups and are mounted on each metal layer (6) normally or inversely; and the LED bare chips (1) in each group and the LED bare chips in the plurality of groups are connected through the metal layers (6) to form circuits. The manufacture method comprises the steps of pretreatment of the metal substrate, formation of the heat conduction insulating layer, the metal layers and the welding prevention layer as well as the encapsulation of the LED bare chips.

Owner:NANKER GUANGZHOU SEMICON MFG

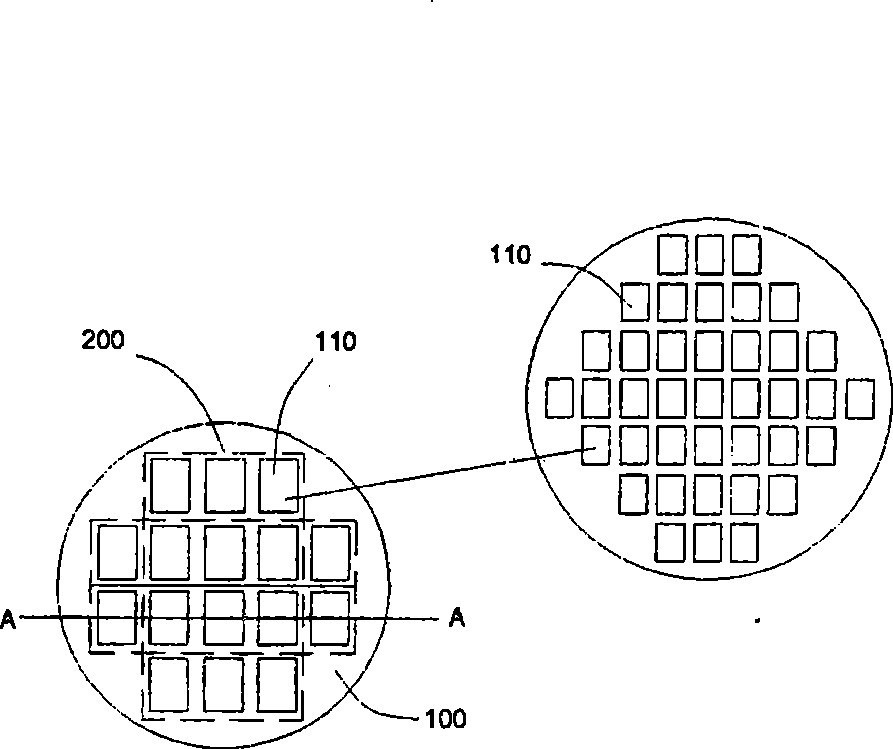

Packaging structure with reconfiguration chip and method thereof

ActiveCN101621041AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

The invention discloses a packaging structure with a reconfiguration chip, comprising a chip, a first high polymer material layer, a sealing compound body, a second high polymer material layer and a base plate; wherein, the active surface of the chip is configured with a plurality of solder pads; the first high polymer material layer covers the active surface of the chip and is electrically connected with the solder pads by a plurality of conducting posts; the sealing compound body is used for covering the four surfaces of the chip; the second high polymer material layer covers the sealing compound body and the first high polymer material layer and exposes out of a plurality of conducting posts; a plurality of fan-shaped metal wire sections cover the second high polymer material layer, and one end of each metal wire section is electrically connected with each conducting post; a plurality of conducting elements are electrically connected with the other end of each metal wire section; the base plate is fixedly connected with the lower surface of the chip by an adhesion layer.

Owner:CHIPMOS TECH INC

Encapsulation structure and method for tablet reconfiguration

ActiveCN101477955AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesProtection layerLine segment

The invention relates to a chip reallocated packaging structure which comprises a chip with an active surface and a lower surface, and a plurality of weld pads allocated on the active surface; a packaging body is used for packaging the chip and exposing the weld pads on the active surface; one ends of a plurality of fanned-out wire sections are electrically connected every weld pad; a protective layer is used for covering the active surface of the chip and every wire section and exposing the other ends of the wire sections; and a plurality of electrically connected elements are electrically connected with the other ends of the wire sections, wherein, the packaging body adopts a two-stage thermosetting cement material.

Owner:CHIPMOS TECH INC

Encapsulation structure and method for tablet reconfiguration

ActiveCN101477956AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesLine segmentElectrical and Electronics engineering

The invention relates to a chip reallocated packaging structure which comprises a chip and a plurality of weld pads allocated on the active surface of the chip; a packaging body is used for packaging the chip and exposing the weld pads; a polymer material layer with at least one seam covers the active surface of the chip, and each weld pad is exposed from the seam; one ends of a plurality of fanned-out wire sections are electrically connected every weld pad; a protective layer is used for covering the active surface of the chip and every wire section and exposing the other ends of the wire sections; and a plurality of electrically connected elements are electrically connected with the other ends of the wire sections, wherein, the packaging body adopts a two-stage thermosetting cement material.

Owner:CHIPMOS TECH INC

Encapsulating structure and encapsulating method of chip

ActiveCN101567322AReduce packaging costsLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringLine segment

The invention relates to an encapsulating structure of a chip, which comprises a chip holding shelf, the chip, an encapsulating body, a plurality of patterning metal line sections, a plurality of patterning protective layers, a plurality of patterning UBM layers and a plurality of conducting elements, wherein the chip holding shelf is provided with a chip holding area, the front face of the chip holding area is provided with an adhesion layer; the active face of the chip is provided with a plurality of weld pads, and the back face of the chip is formed on the adhesion layer of the chip holding shelf; the encapsulating body is covered around the chip holding shelf provided with the chip and exposes the weld pads on the active face of the chip, and the height of the encapsulating body is larger than that of the chip; one end of the patterning metal line section is electrically connected with the weld pads, and the other end extends outside and is covered on one surface of the encapsulating body; the patterning protective layers are covered on the patterning metal line sections and expose the part of a surface of a fan-out structure formed in such a way that the patterning metal line sections extend outside the active face of the chip; the patterning UBM layers are respectively formed on the part of the surface of each fan-out structure and electrically connected with the patterning metal line sections; and the conducting elements are electrically connected with the patterning metal line sections by the UBM layers.

Owner:CHIPMOS TECH INC

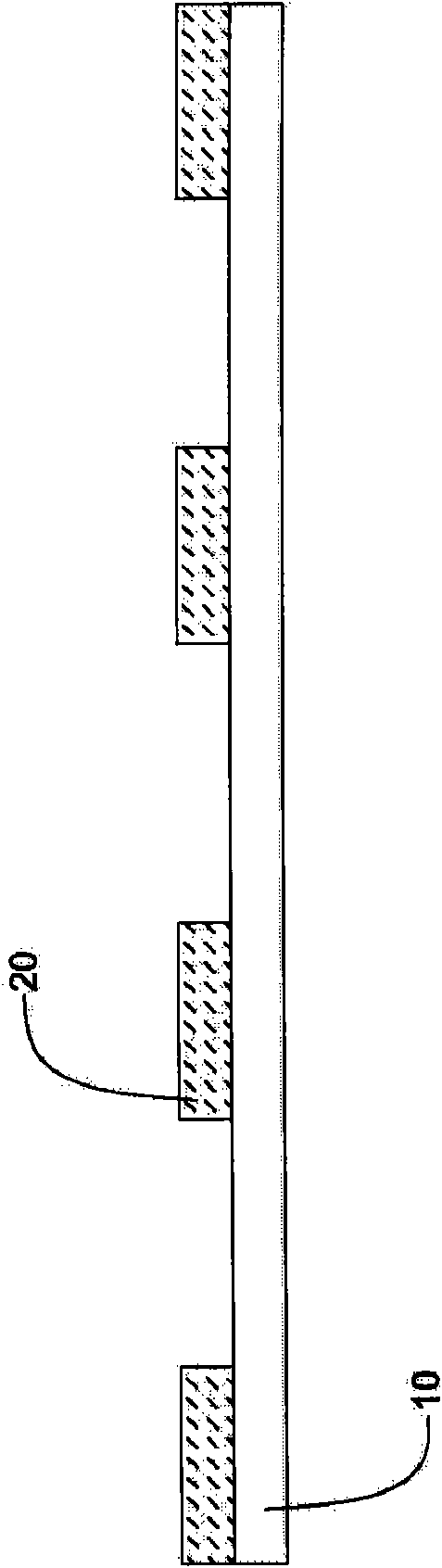

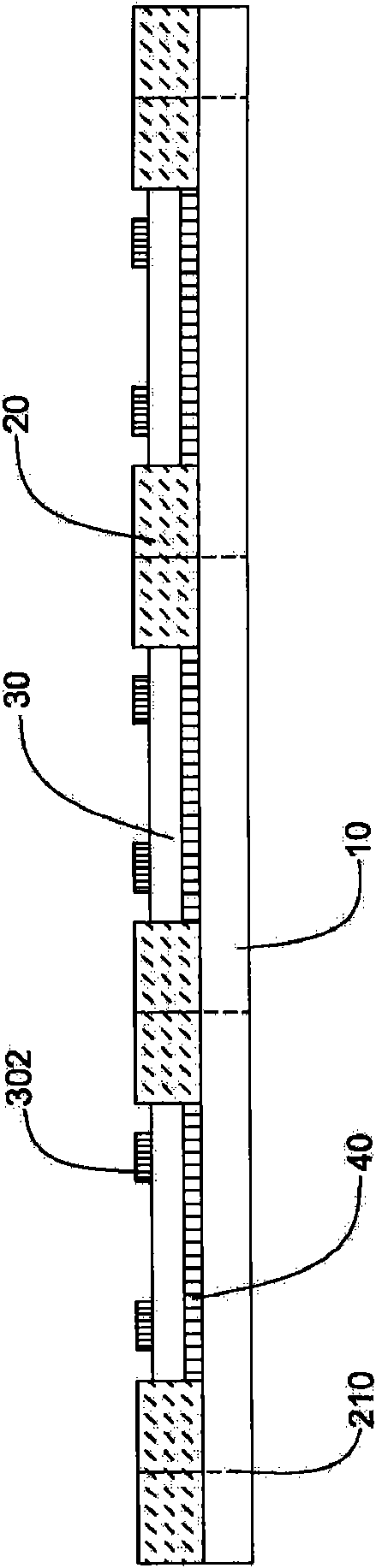

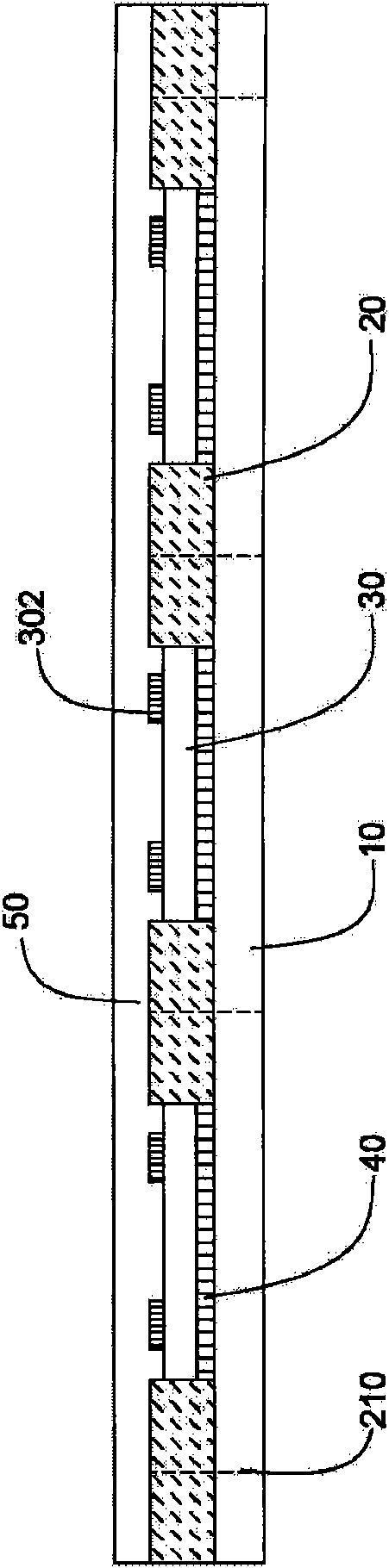

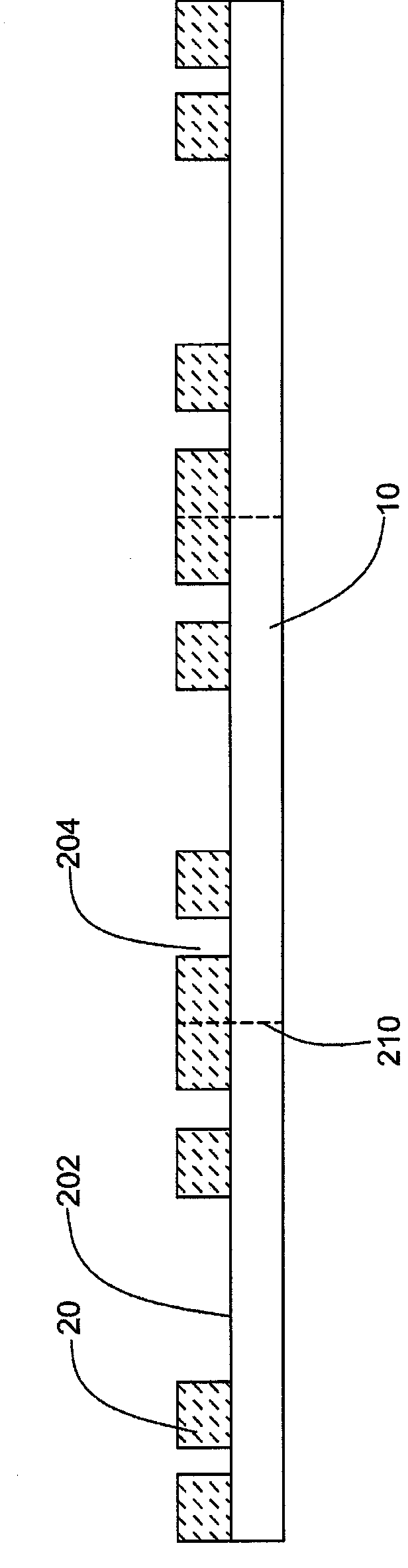

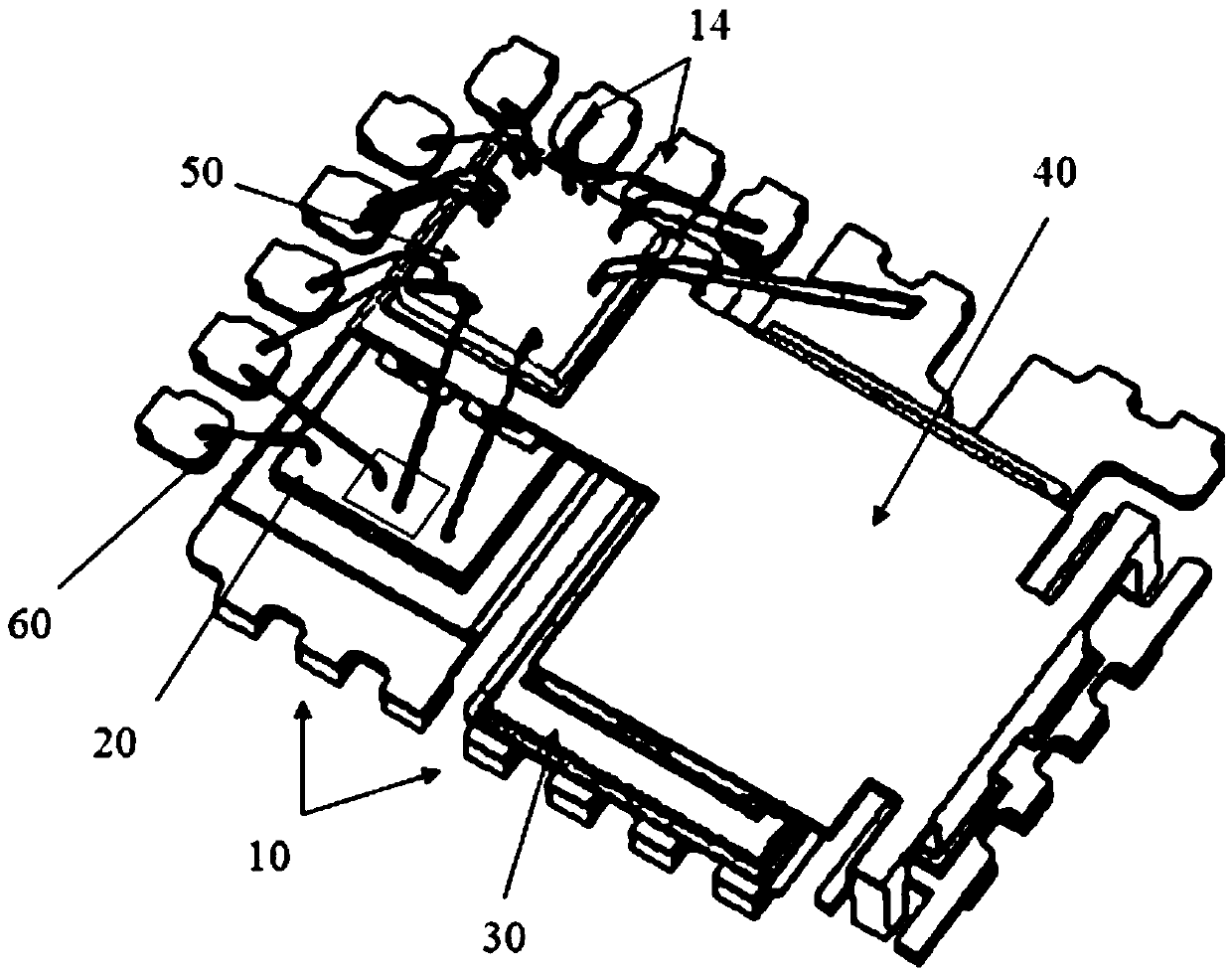

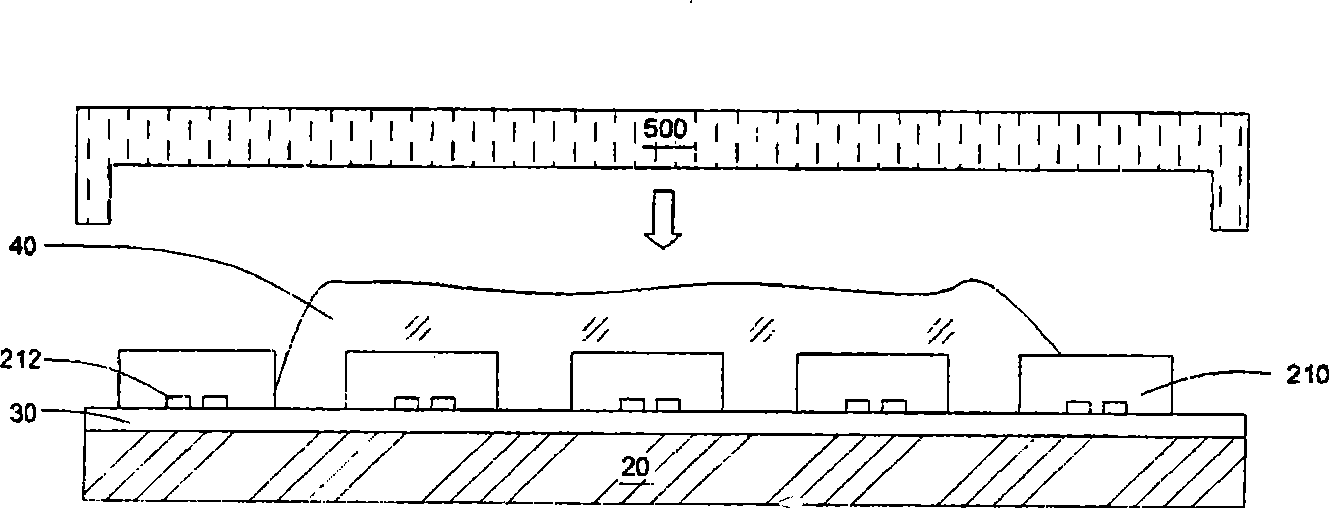

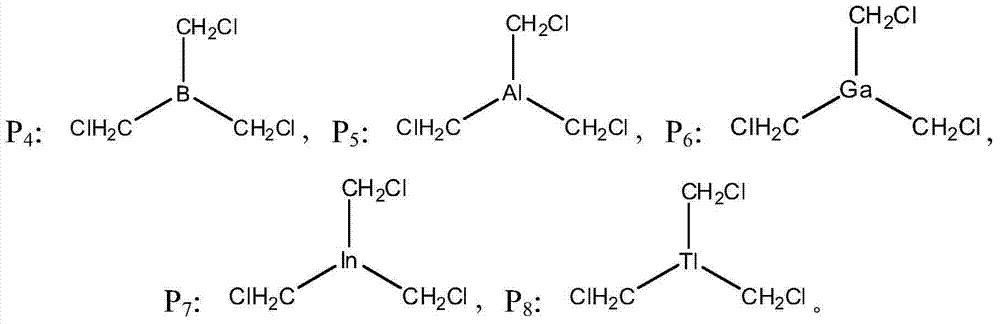

Chip stacking structure and forming method thereof

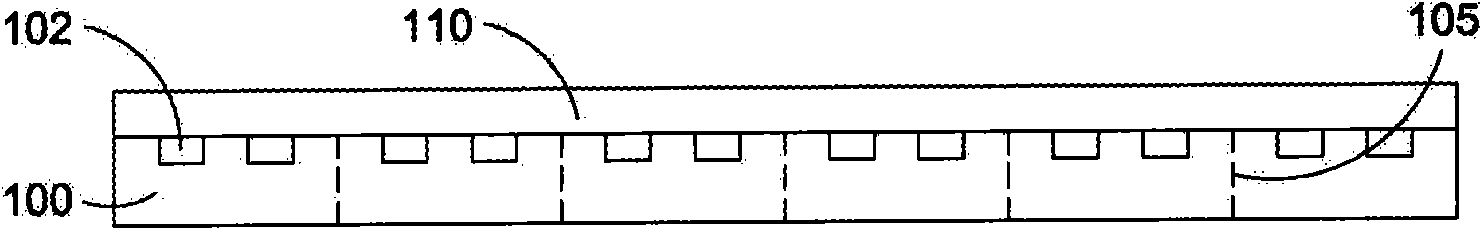

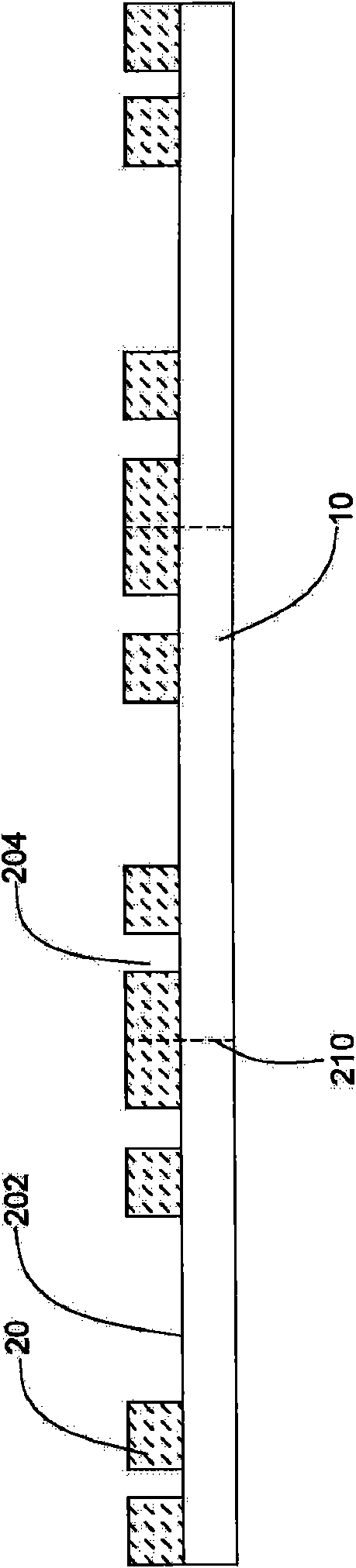

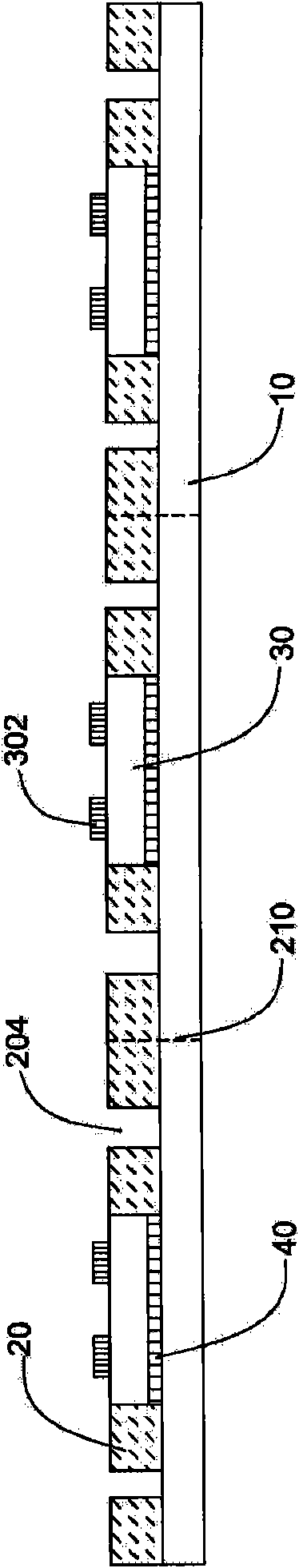

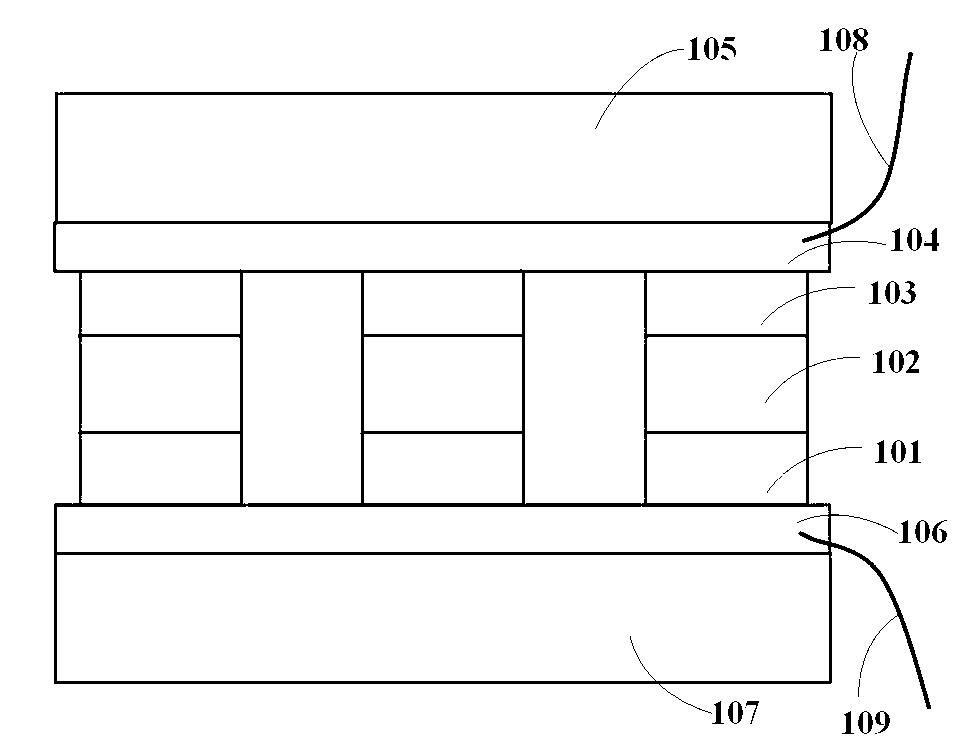

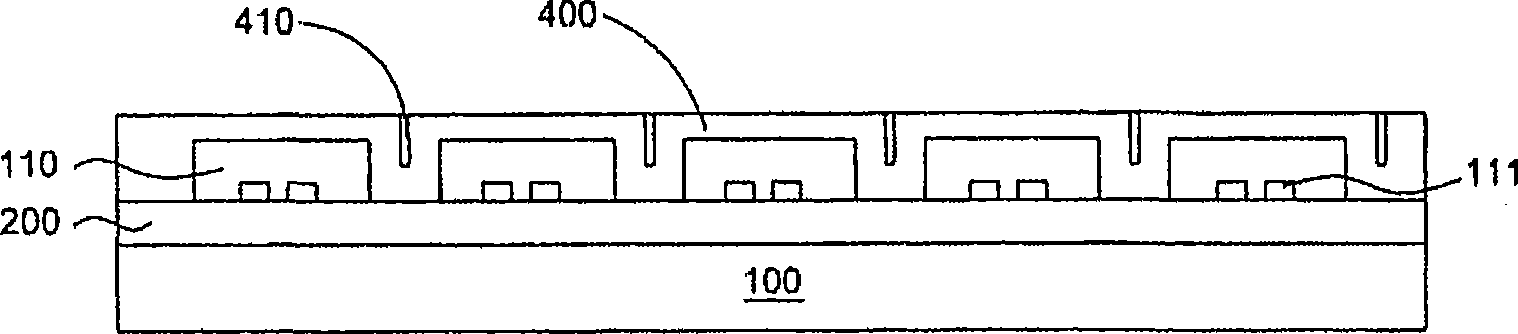

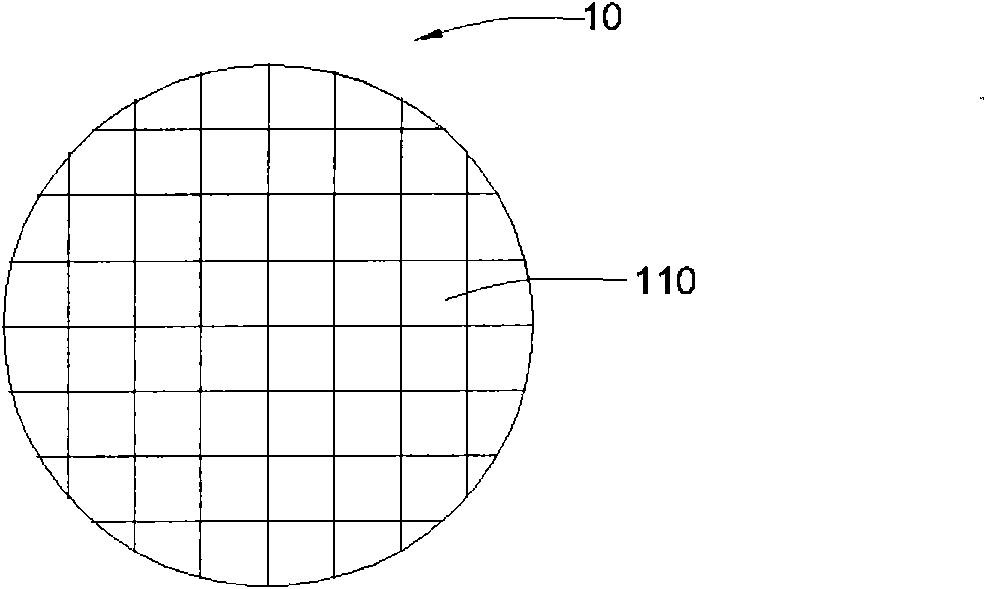

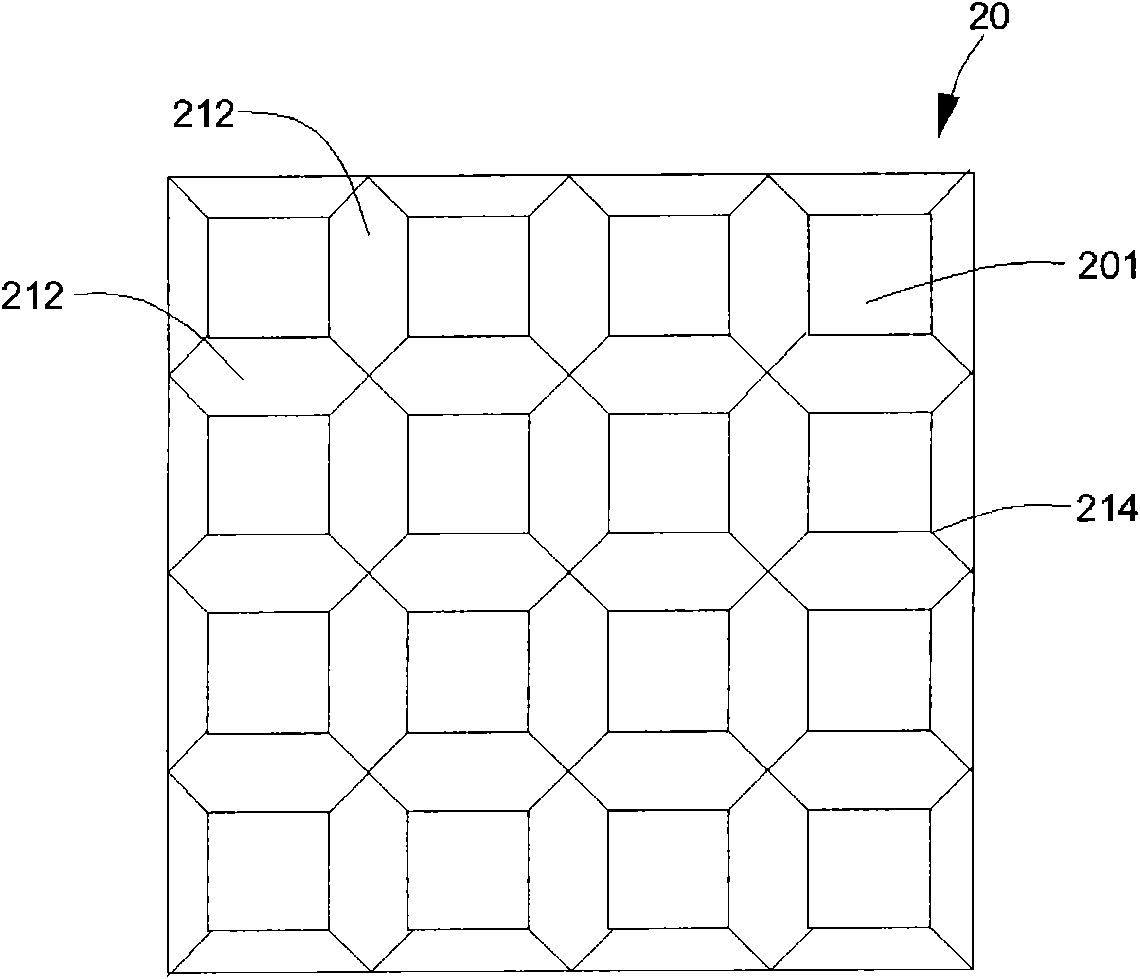

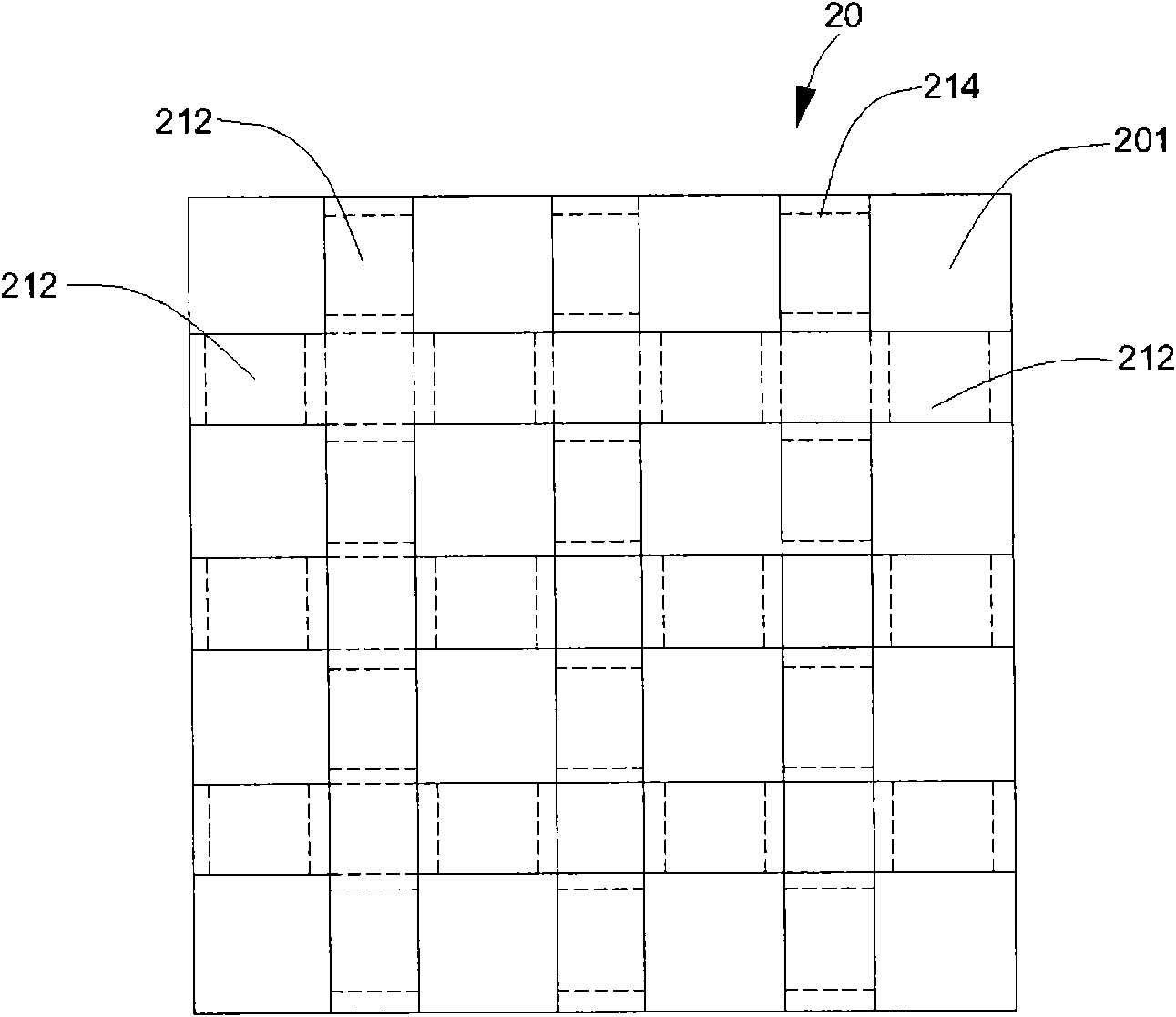

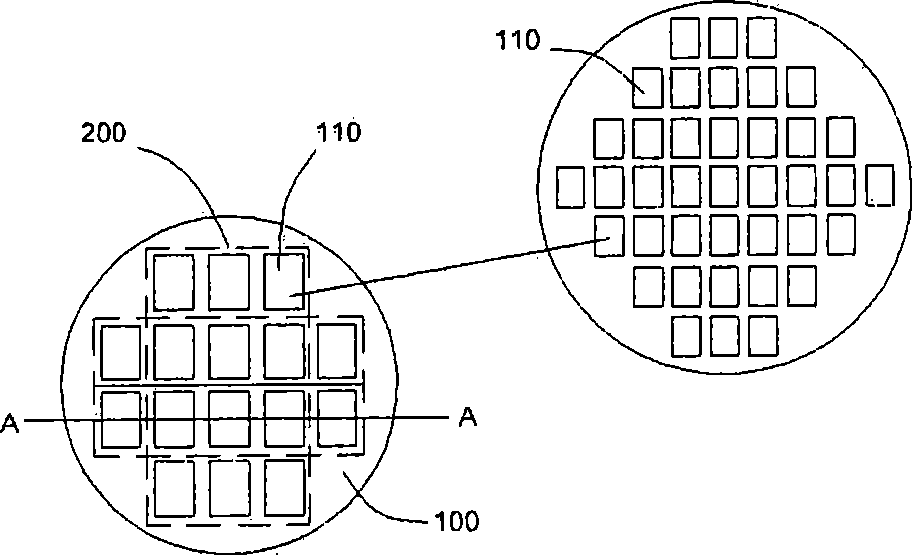

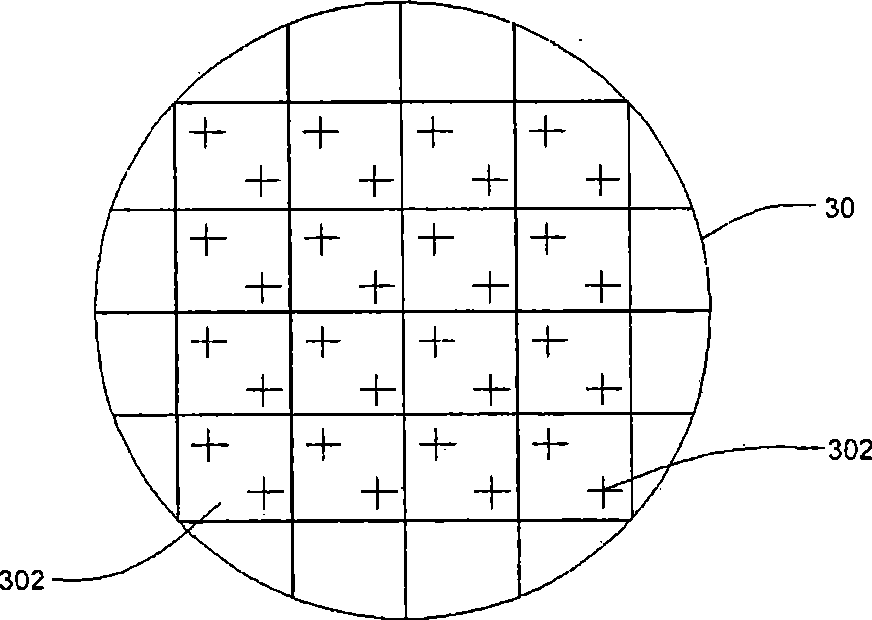

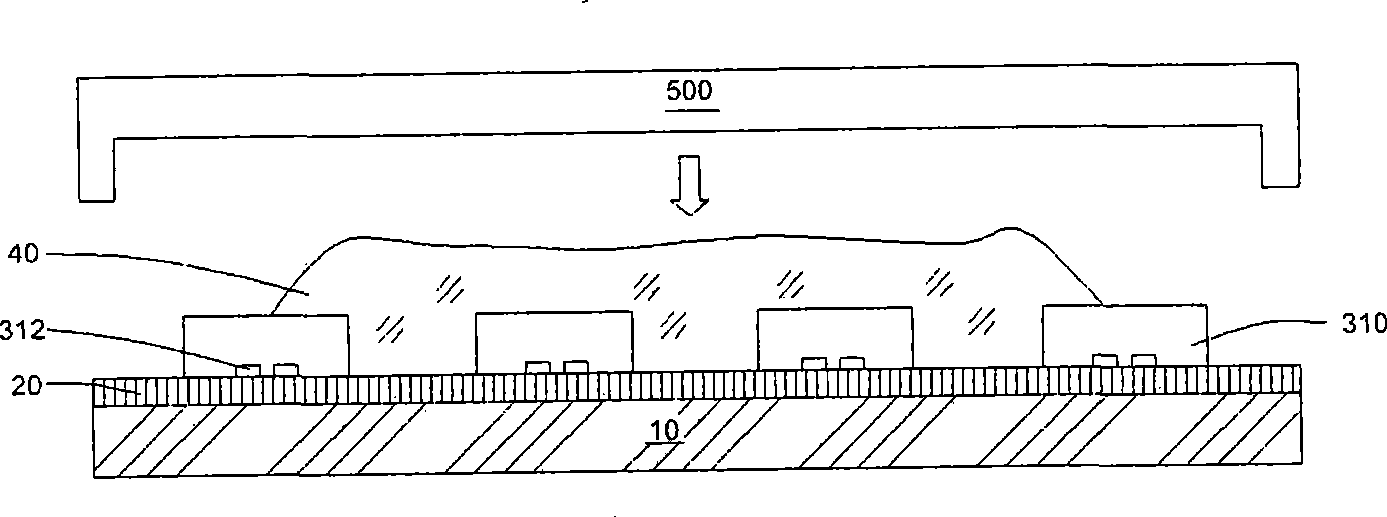

ActiveCN101615583AReduce packaging costsSave packaging materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringSoldering

The invention relates to a chip packaging structure and a forming method thereof. The packaging structure comprises a chip, a packaging body, a first patterned protection layer, a metal layer, a second patterned protection layer, a plurality of patterned UBM layers and a plurality of conductive assemblies, wherein a plurality of soldering pads and adhesion layers are respectively arranged on an active surface and a back surface of the chip; the packaging body is annularly covered on four surfaces of the chip so as to expose the soldering pads of the chip out and is provided with a plurality of through holes; the first patterned protection layer is formed on the partial surface of the packaging body and the active surface of the partial chip and exposes the soldering pads and the through holes out; the metal layer is covered on the partial surface of the first patterned protection layer, and is electrically connected with the soldering pads and filled in the through holes; the second patterned protection layer is covered on the first patterned protection layer and a part of metal layer and exposes the partial surface of the metal layer out; the patterned UBM layers are formed on the partial surface of the exposed metal layer and the partial surface of the second patterned protection layer and are electrically connected with the metal layer; and the conductive assemblies are formed on the patterned UBM layers and electrically connected with the metal layer through the patterned UBM layers.

Owner:CHIPMOS TECH INC

Stack encapsulation method with grains reconfigured and stack construction thereof

ActiveCN101452862AAvoid damageImprove yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringLine segment

The invention relates to an encapsulation structure for reconfiguring crystal grains. The encapsulation structure comprises a crystal grain, an encapsulating body, a plurality of conduction columns, a plurality of patternized metal wire sections, a patternized protective layer and a plurality of conduction elements, wherein the active surface of the crystal grain is provided with a plurality of welding pads; the encapsulating body covers the crystal grain and exposes the plurality of the welding pads on the crystal grain; the plurality of the conduction columns run through the encapsulating body to form a first conduction end and a second conduction end at two ends respectively; the plurality of the welding pads of the crystal grain are in electric connection with each first conduction end of the plurality of the conduction columns through each patternized metal wire section; the patternized protective layer is used for covering the plurality of the welding pads of each crystal grain and the plurality of the patternized metal wire sections and exposes one surface outwards extended from part of the plurality of the patternized metal wire sections; and the plurality of the conduction elements are in electric connection with the exposed surface outwards extended from part of the patternized metal wire sections.

Owner:CHIPMOS TECH INC

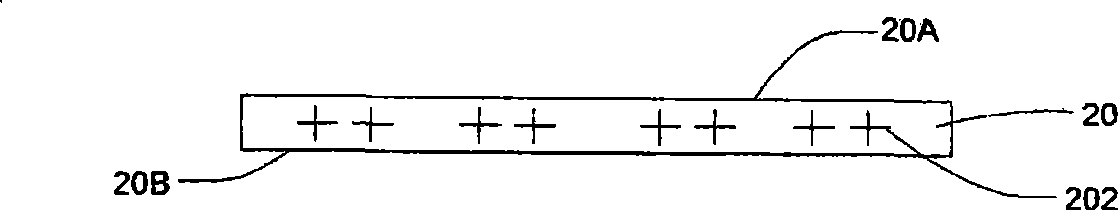

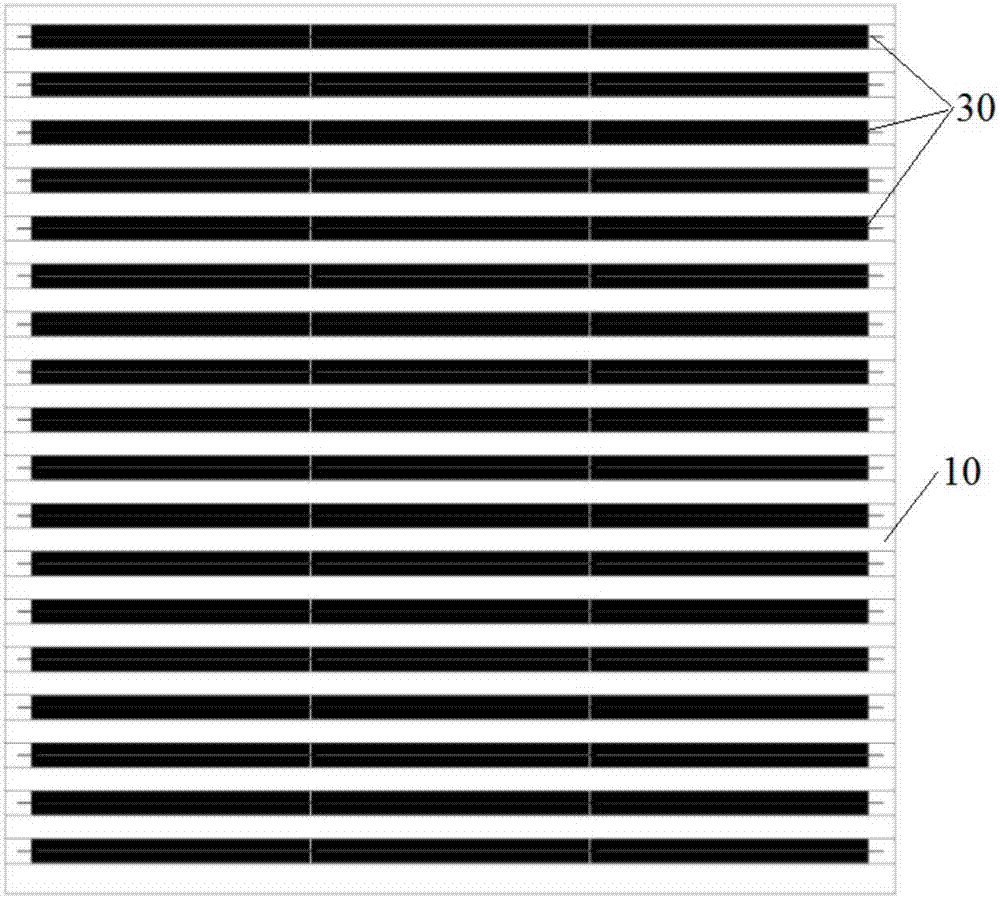

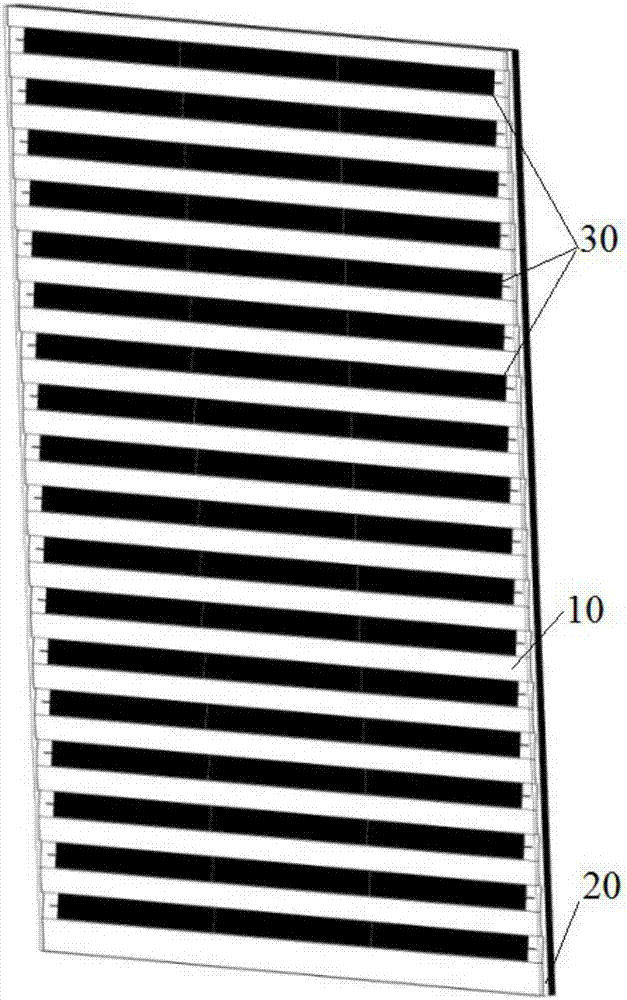

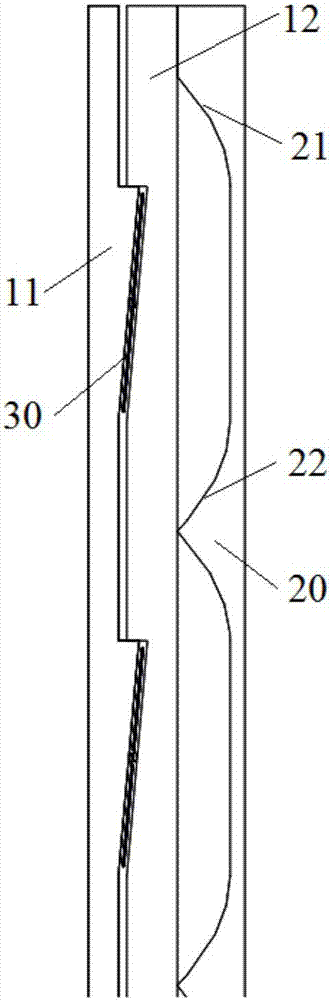

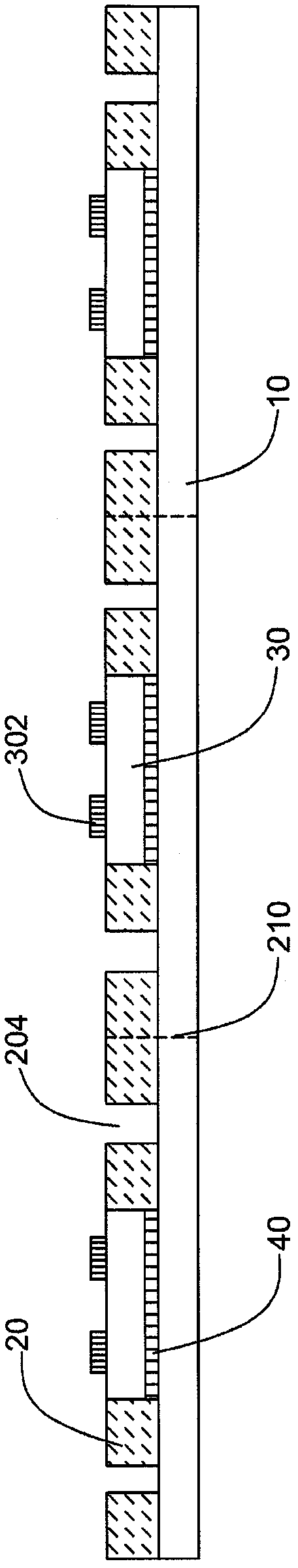

Double-sided photovoltaic assembly

PendingCN107425805AImprove power generation efficiencyReduce usagePhotovoltaicsPhotovoltaic energy generationGenerating capacityEngineering

The invention discloses a double-sided photovoltaic assembly, which comprises a front panel and a back panel, and is characterized in that the front panel is made of a light transmitting material, a plurality of double-sided photovoltaic cells are fixedly arranged on the front panel, the double-sided photovoltaic cells are arranged in an inclined manner, the plurality of double-sided photovoltaic cells are arranged in parallel, the adjacent double-sided photovoltaic cells are provided with an interval, the back panel is provided with a plurality of reflecting surface units, each reflecting surface unit corresponds to one double-sided photovoltaic cell, the reflecting surface unit comprises a first reflecting surface and a second reflecting surface, the first reflecting surface and the second reflecting surface are respectively located at two sides of the double-sided photovoltaic cell, and the first reflecting surface and the second reflecting surface face towards the back of the double-sided photovoltaic cell. The double-sided photovoltaic assembly is compact in structure, can reduce the usage of the cells, improves the generating capacity of the sytem and facilitates a root to automatically clean the photovoltaic assembly.

Owner:ARCTECH SOLAR HLDG CO LTD

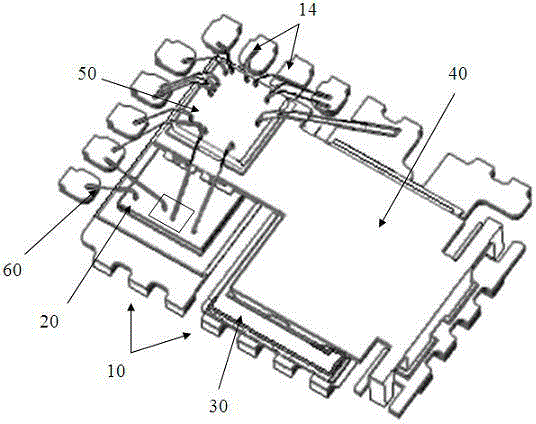

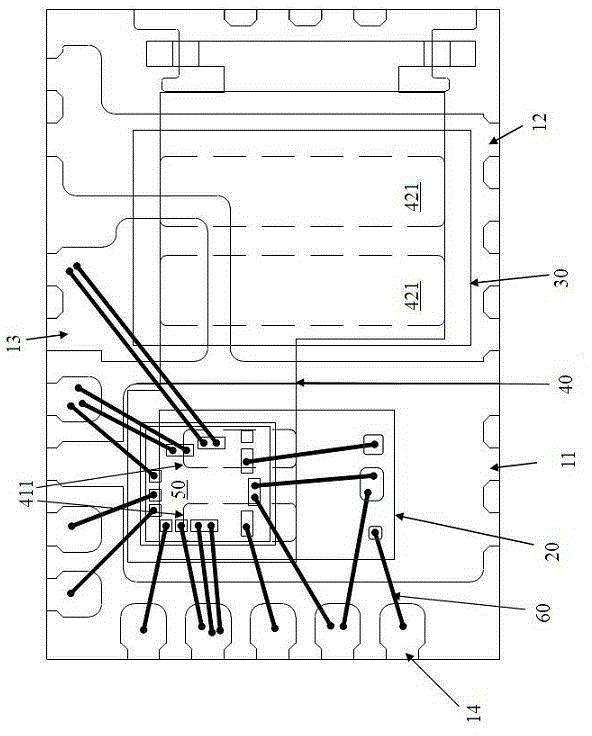

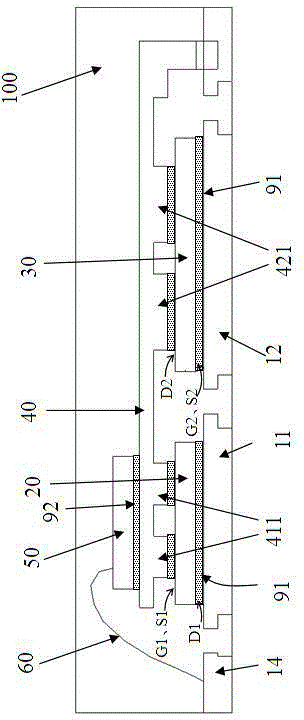

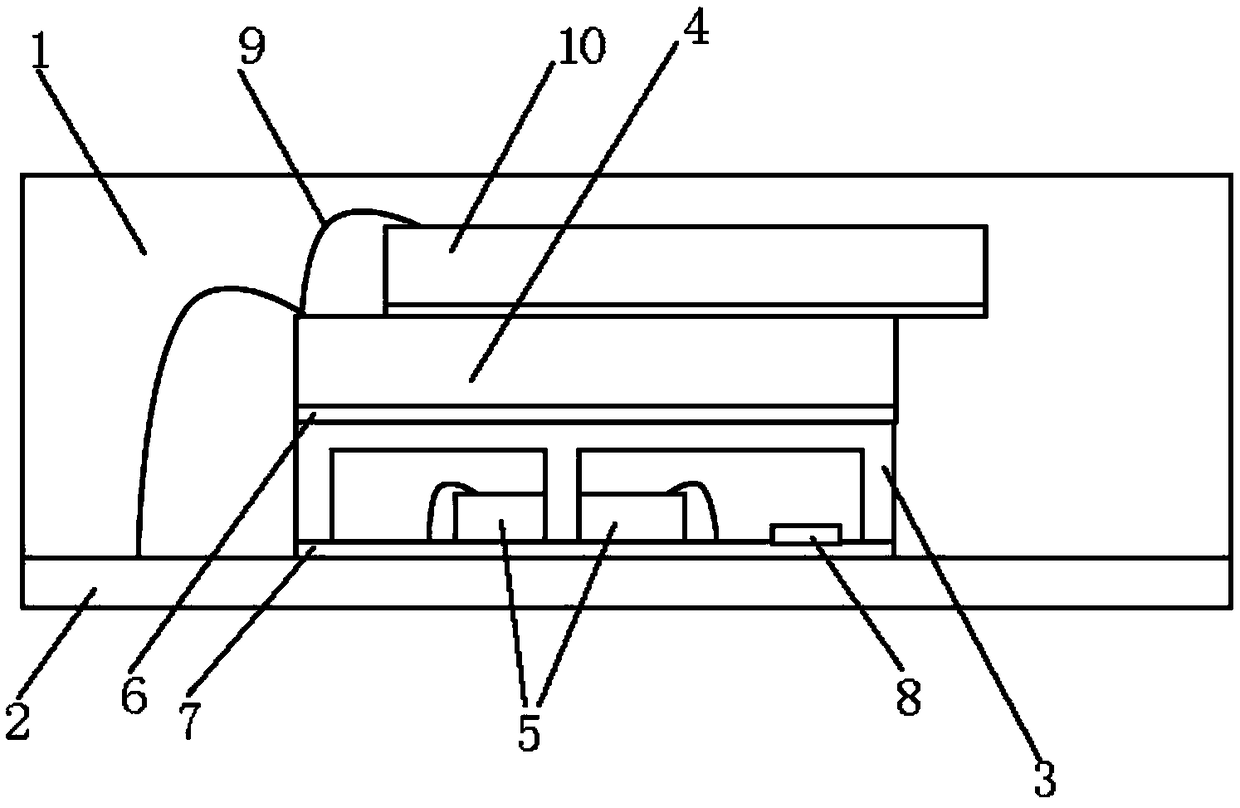

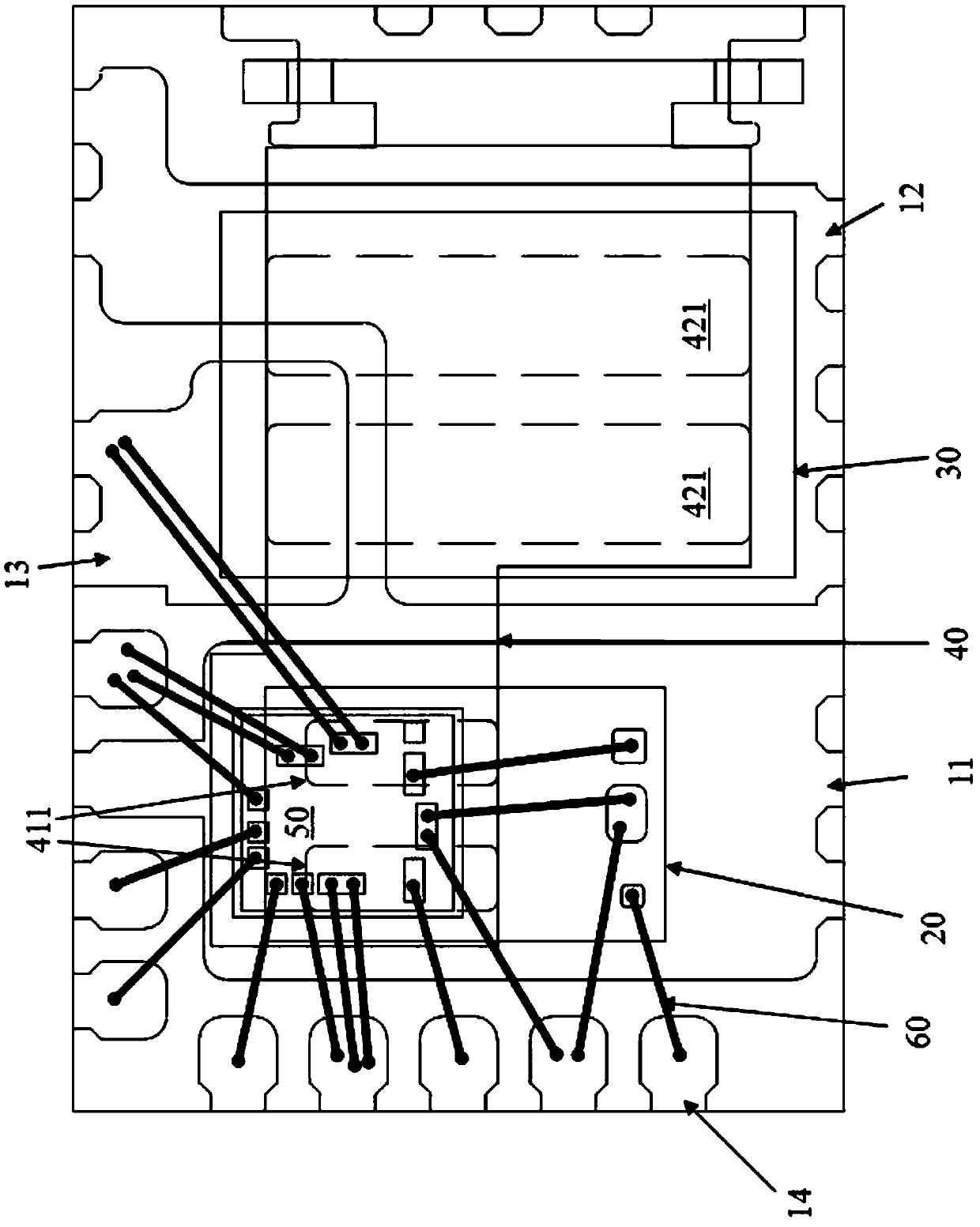

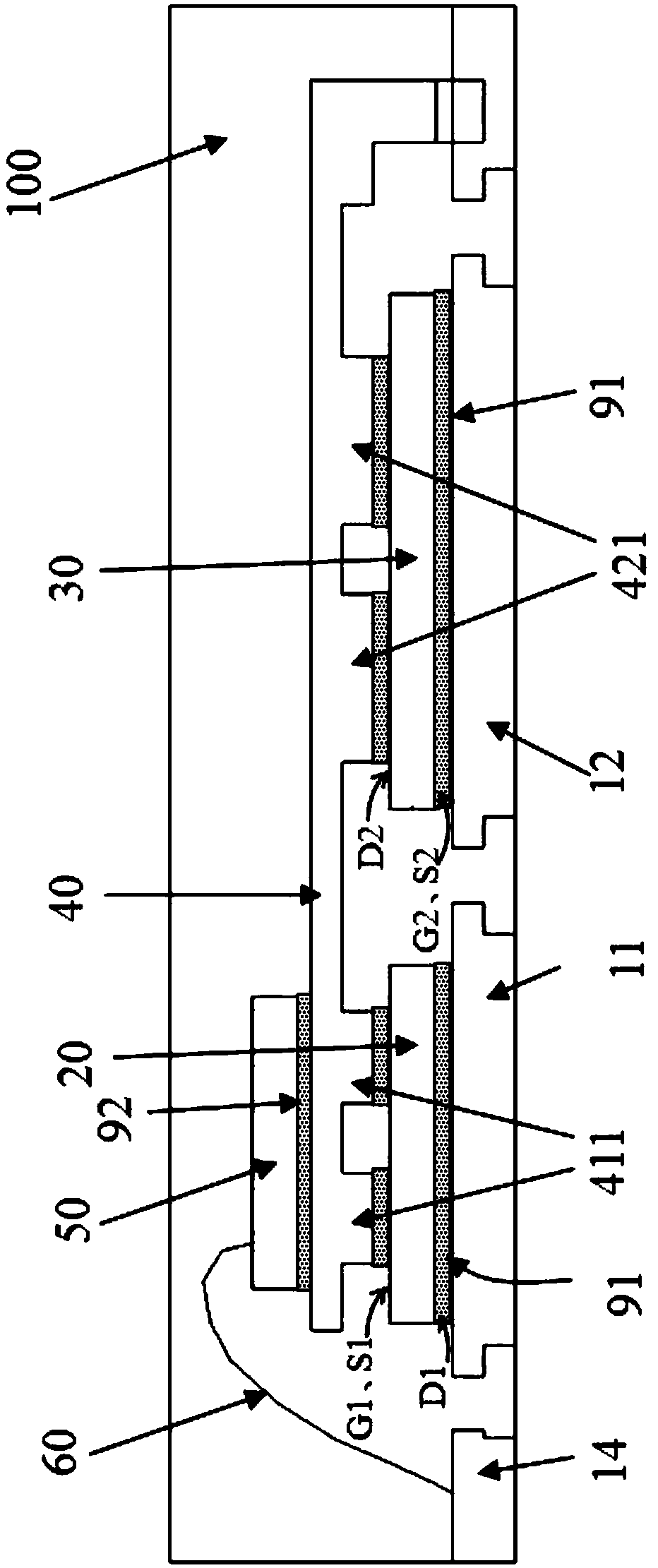

Multi-chip laminating type packaging structure and packaging method thereof

ActiveCN104681525AImprove performanceSimple processSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingIntegrated circuit

The invention relates to a multi-chip laminating type packaging structure and a packaging method thereof. The packaging structure has the advantages that a source of an HS chip and a drain of an LS chip are electrically connected by a connecting sheet, so the conductive loss and switch loss are reduced, and the heat dissipation efficiency is improved; an IC (integrated circuit) chip is connected with the connecting sheet in an insulating way, and the IC chip can be laminated above the planes of the HS chip and the LS chip, so as to effectively reduce the size of the packaged device; the bottom surfaces of a first chip carrying table and a second chip carrying table are exposed out of a plastic packaging body; multiple methods are set, and the surface of one part, not connecting with the IC chip, of the connecting sheet is exposed out of the plastic packaging body; or the connecting sheet is further connected with a heat radiating plate, and the surface of one part of the heat radiating plate is exposed out of the plastic packaging body; or the heat insulating plate is inserted into a reserved notch of the plastic packaging body, so as to touch the connecting sheet and radiate the heat.

Owner:ALPHA & OMEGA SEMICON INT LP

Method for manufacturing package structure with reconfigured chip by metal projection

ActiveCN101436553AAvoid damageImprove pass rateSemiconductor/solid-state device detailsSolid-state devicesArray data structureLine segment

The invention relates to an encapsulating structure for rearranging a chip, which comprises a chip, a plurality of patterning metal segments, an encapsulating body, a plurality of conducive poles, a pattering protective layer and a plurality of conductive components, wherein one active surface of the chip is provided with a plurality of welding pads, each of the plurality of the patterning metal segments is electrically connected with the plurality of the welding pads on the active surface of the chip, the plurality of the conducive poles are formed on the plurality of the patterning metal segments, the encapsulating body is used for wrapping five surfaces of the chip and exposing the plurality of the patterning metal segments, the plurality of the conducive poles are formed at the other ends of the plurality of the patterning metal segments, a pattering protective layer is used for wrapping the plurality of the patterning metal segments and exposing one surface of the plurality of the conducive poles as a conductive end point, and the plurality of the conductive components are electrically connected with the surfaces of the exposed plurality of the conducive poles in a mode of array arrangement.

Owner:CHIPMOS TECH INC

Encapsulating structure and encapsulating method for reconfiguring chip

InactiveCN101609822AImprove yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention relates to an encapsulating structure and an encapsulating method for reconfiguring a chip. The encapsulating structure comprises a plurality of welding pads configured on an active surface of the chip; first polymer material layers covering on the active surface of the chip and exposing the plurality of the welding pads; a plurality of conductive columns configured among the first polymer material layers and electrically connected with each welding pad; a sealing compound body for coating the chip and exposing the polymer material layers and the conductive columns; a second polymer material layer covering on the first polymer material layers and the sealing compound body and exposing the plurality of the conductive columns; a plurality of fan-out metal wire sections which are configured above the second polymer material layer and of which one ends of the metal wire sections electrically are connected with the conductive columns; and a plurality of conductive elements electrically connected with the other ends of the metal wire sections.

Owner:CHIPMOS TECH INC

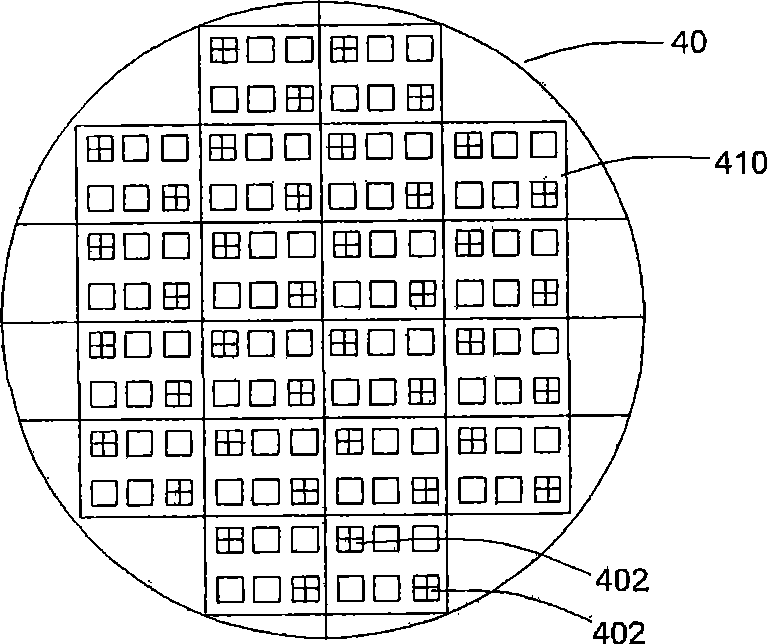

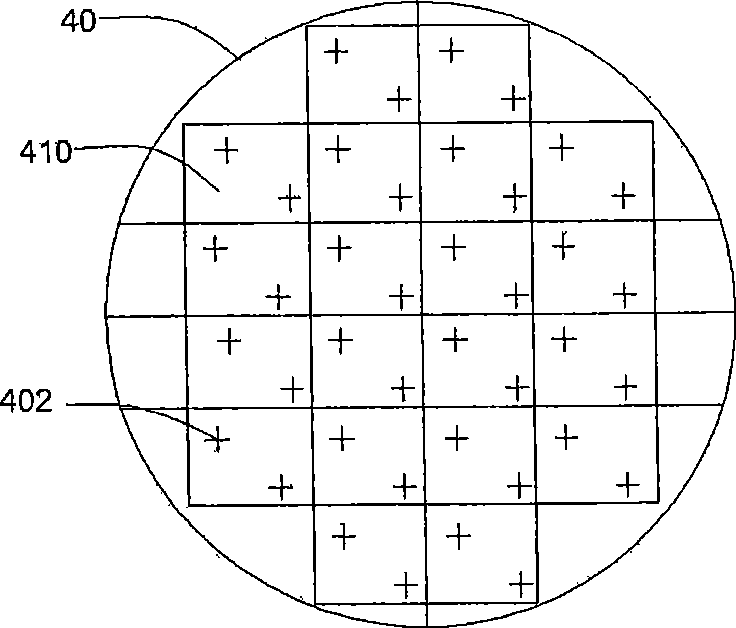

Chip reconfiguration structure provided with analog baseplate and packaging method thereof

ActiveCN101615584AAccurate configurationReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

The invention relates to a packaging structure of chip reconfiguration, which comprises a chip, a packaging body, a patterned protection layer, a fan-out patterned metal segment, a second patterned protection layer, a patterned UBM layer and a conductive assembly, wherein the packaging body is annularly covered on four surfaces of the chip so as to expose an active surface and a back surface of the chip out; the patterned protection layer is formed on the surface of the packaging body and covered on the active surface of the chip and exposes a plurality of soldering pads of the chip out; one end of the fan-out patterned metal segment is electrically connected with soldering pads of the chip, and the other end of the fan-out patterned metal segment extends towards the outer side and is covered on the first patterned protection layer; the second patterned protection layer is covered on the patterned metal segment and exposes the partial surface of the patterned metal segment out; the patterned UBM layer is formed on the partial surface of the exposed patterned metal segment; and the conductive assembly is formed on the pattern UBM layer and is electrically connected with the patterned metal segment through the patterned UBM layer.

Owner:CHIPMOS TECH INC

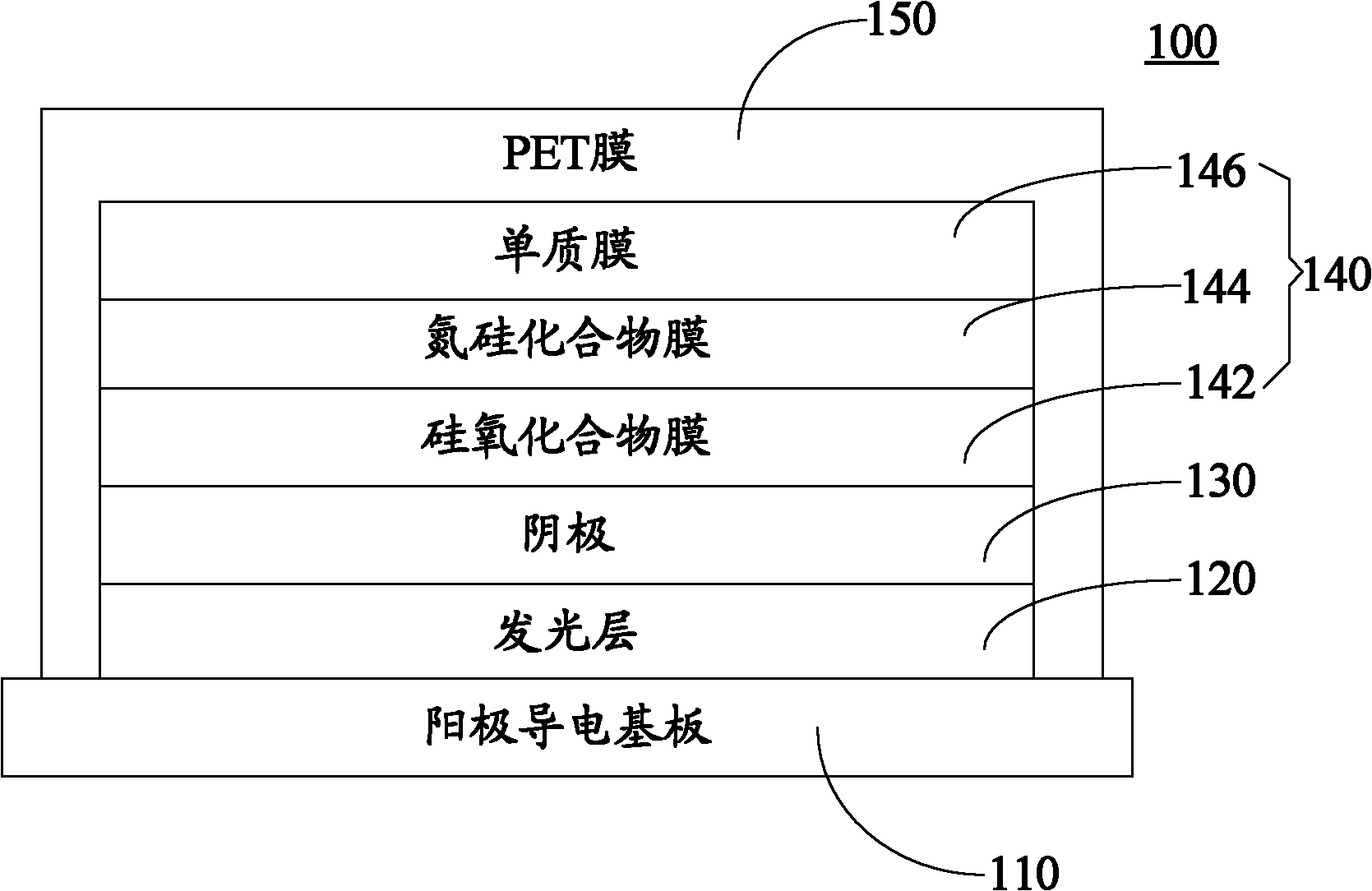

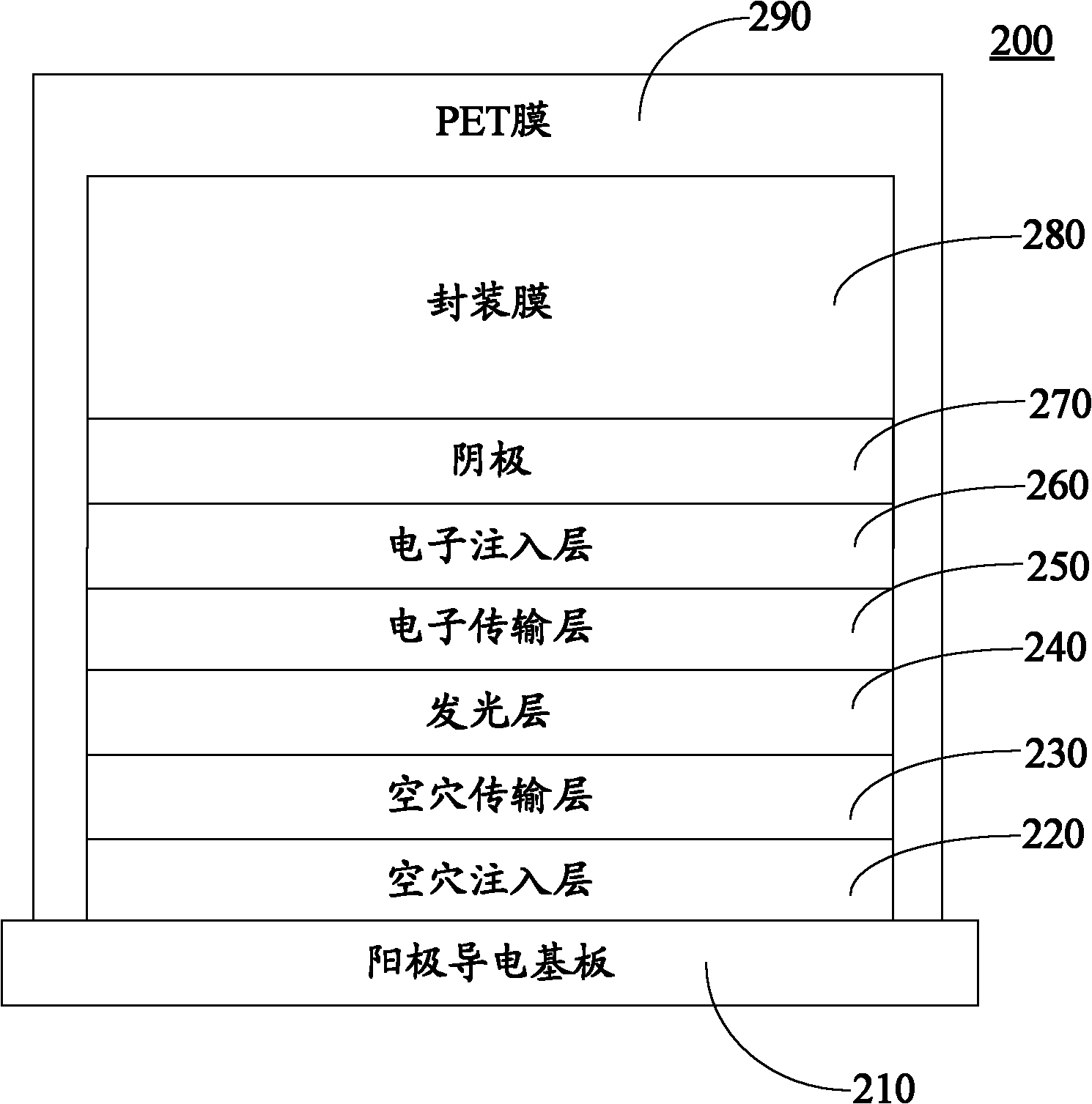

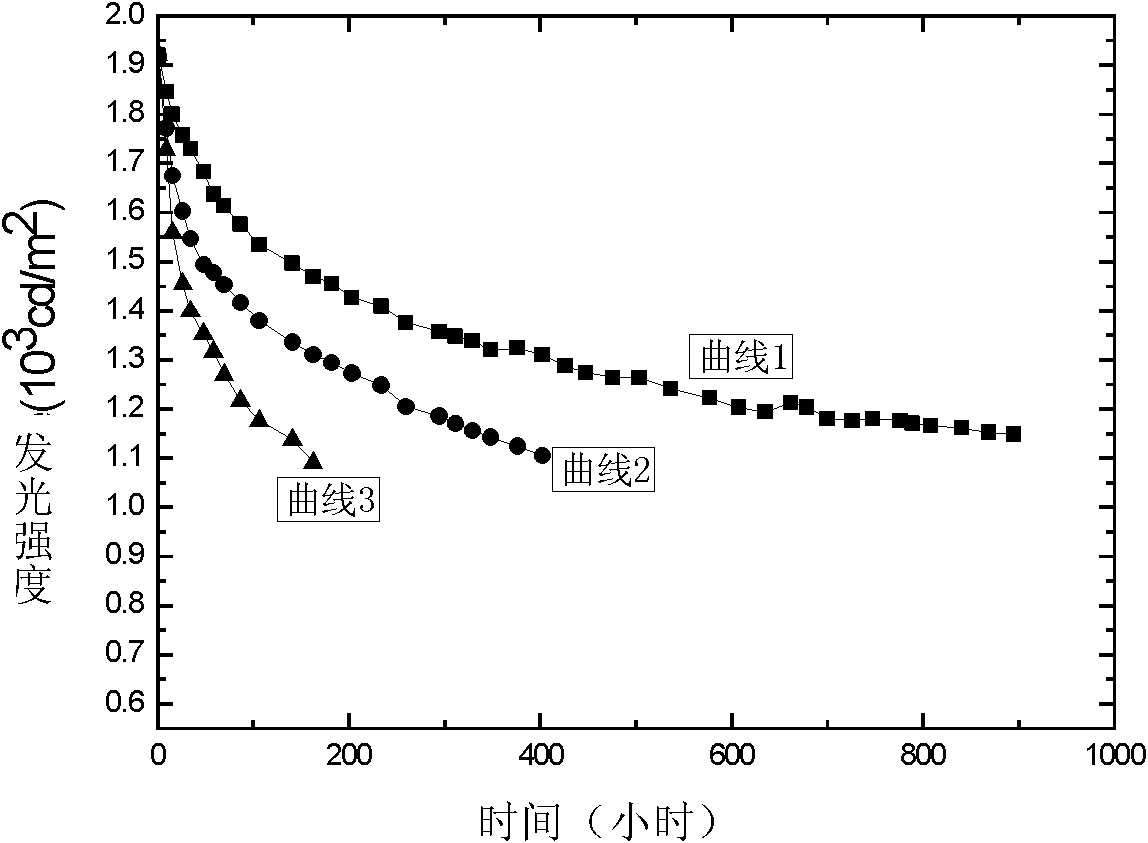

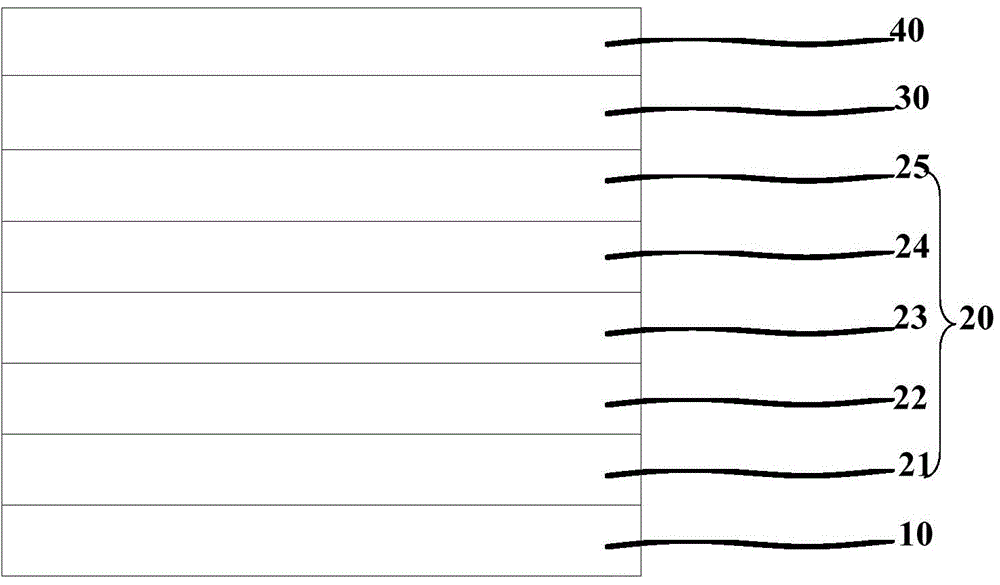

Organic electroluminescence device and manufacturing method thereof

InactiveCN102842683AExtend your lifeSave packaging materialSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSilicon oxygen

The invention relates to an organic electroluminescence device. The organic electroluminescence device comprises an anode conducting substrate, a light-emitting layer, a cathode, and at least one layer of packaging film, wherein the anode conducting substrate, the light-emitting layer and the cathode are stacked in sequence; the packaging films comprise a silicon-oxygen compound film formed on the cathode, a nitrogen-silicon compound film formed on the silicon-oxygen compound film, and an elementary substance film formed on the nitrogen-silicon compound film and formed by metal or like metal of sulfur group or nitrogen group. According to the organic electroluminescence device, the high water and oxygen resistance of the silicon-oxygen compound film, the nitrogen-silicon compound film and the elementary substance film is made full use of, and the erosion of active substances such as external water, oxygen and the like on the organic electroluminescence device is effectively reduced, so that the organic function materials and the electrodes of the device are effectively protected, and the service life of the organic electroluminescence device is remarkably prolonged. In addition, the invention further relates to a manufacturing method for the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

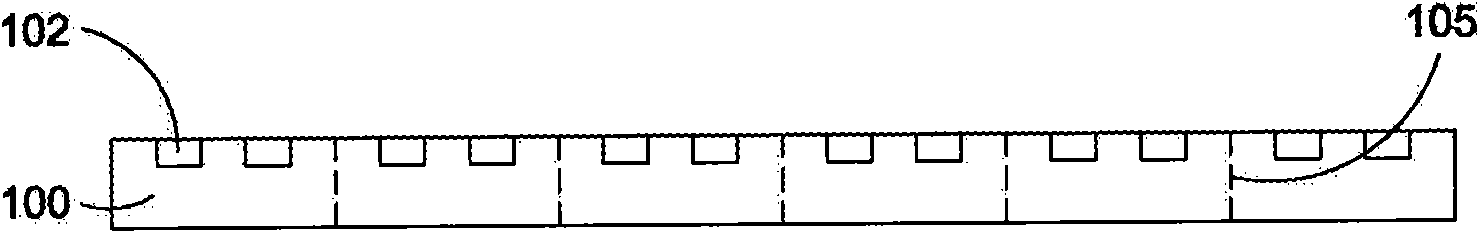

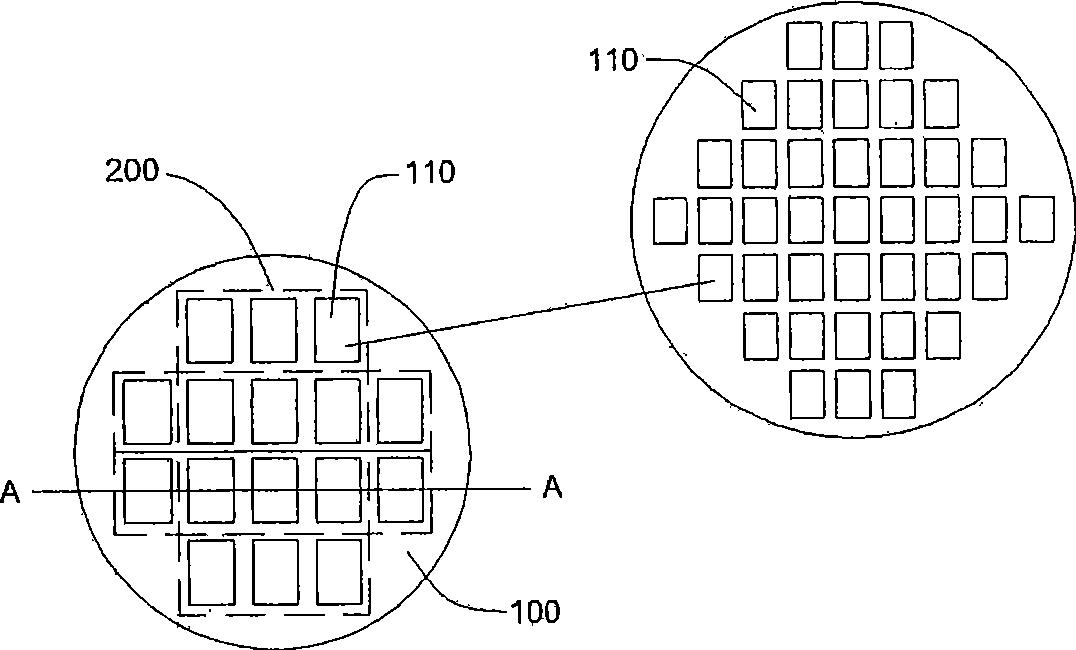

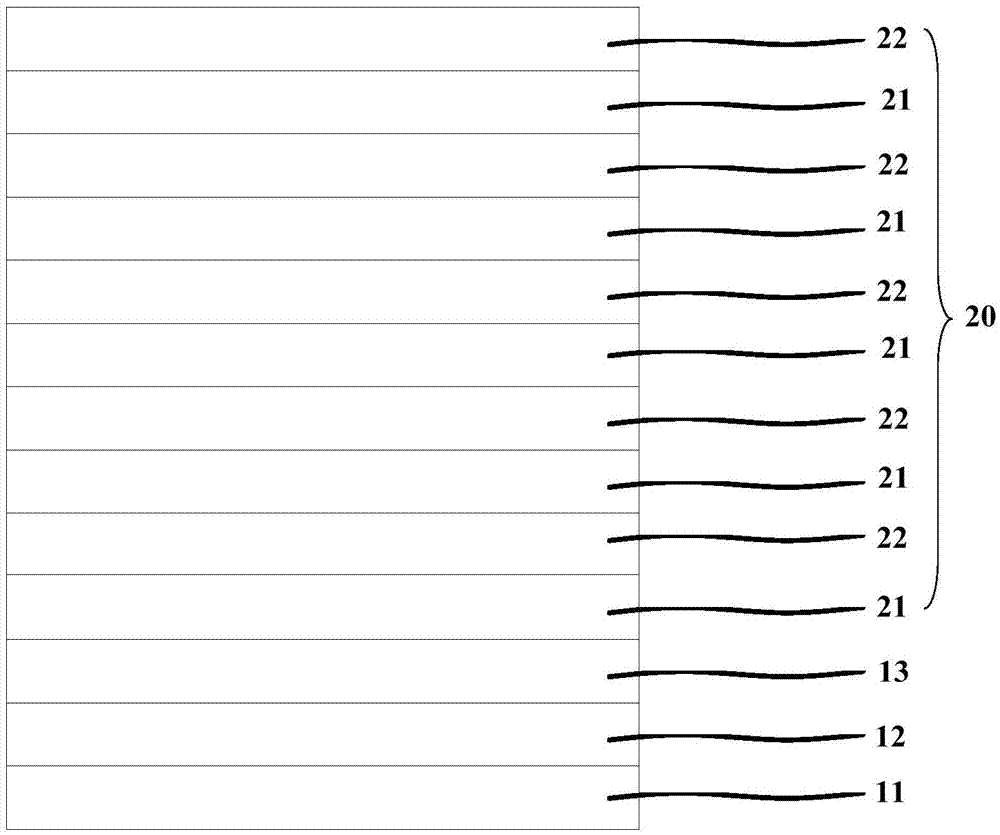

Light-emitting diode device and production method thereof

InactiveCN102800800AExtended service lifeReduce light absorptionSolid-state devicesSemiconductor devicesMetal electrodesLight-emitting diode

The invention discloses a light-emitting diode device and a production method thereof. The production method comprises the following steps of: arranging a first conducting substrate and a second light-transmitting conducting structure respectively on the bottom surface and the top surface of a light-emitting epitaxial structure which at least comprises two light-emitting epitaxial units, so as to form light-emitting diodes arrayed with a high density, without a positive metal electrode and a negative metal electrode, and capable of increasing light emission, wherein the light rays emitted by a light-emitting layer can be effectively taken out, the light absorption phenomena of the metal electrodes can be reduced, the light-emitting efficiency can be increased, heat resistance can be reduced, the service lives of the light-emitting diodes can be prolonged, packaging materials can be saved, and technological processes can be simplified.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

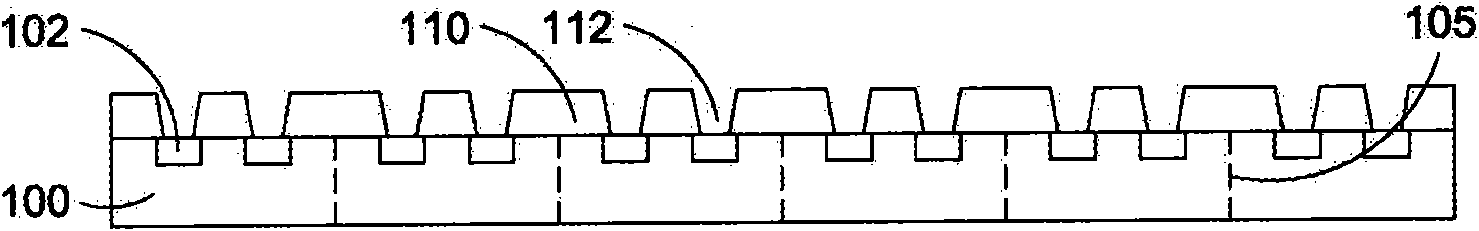

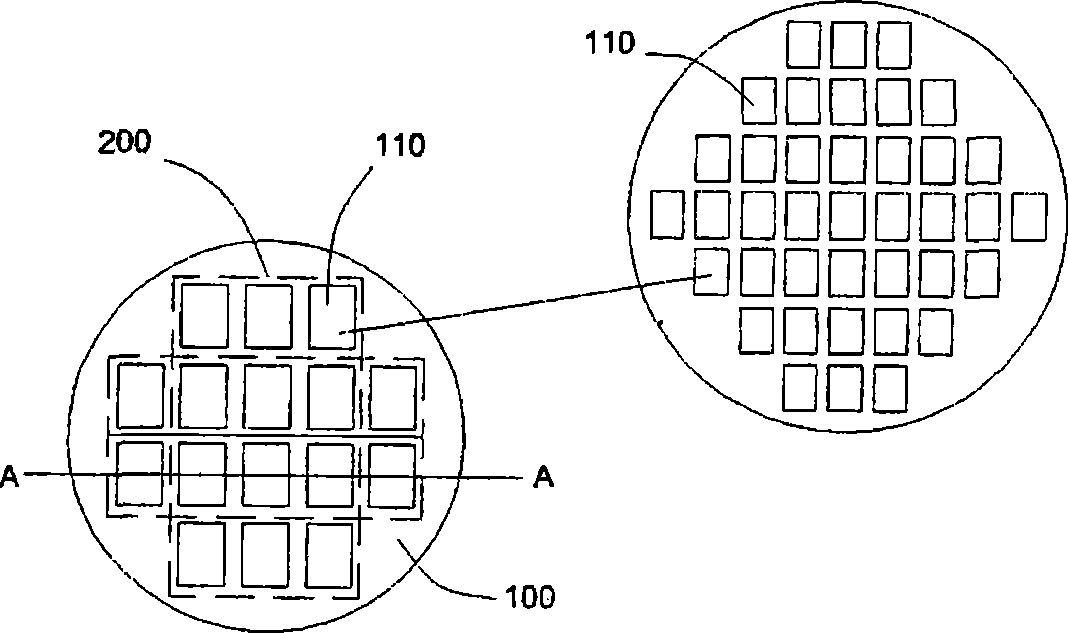

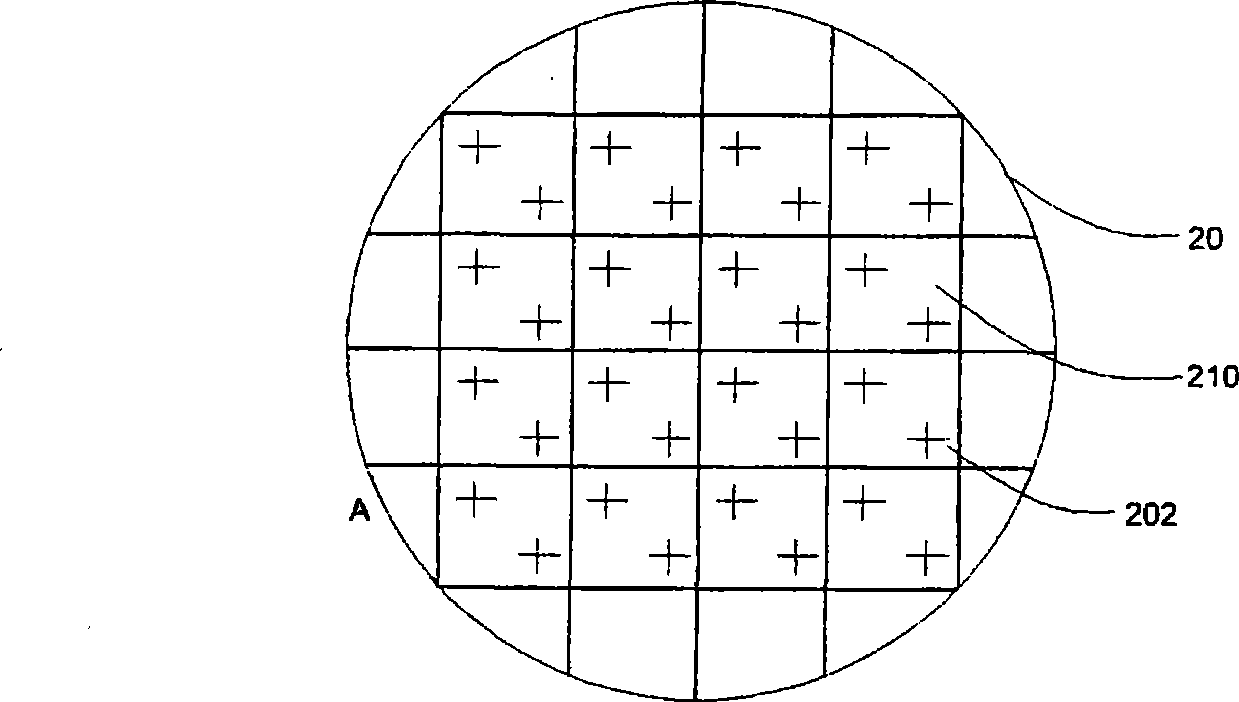

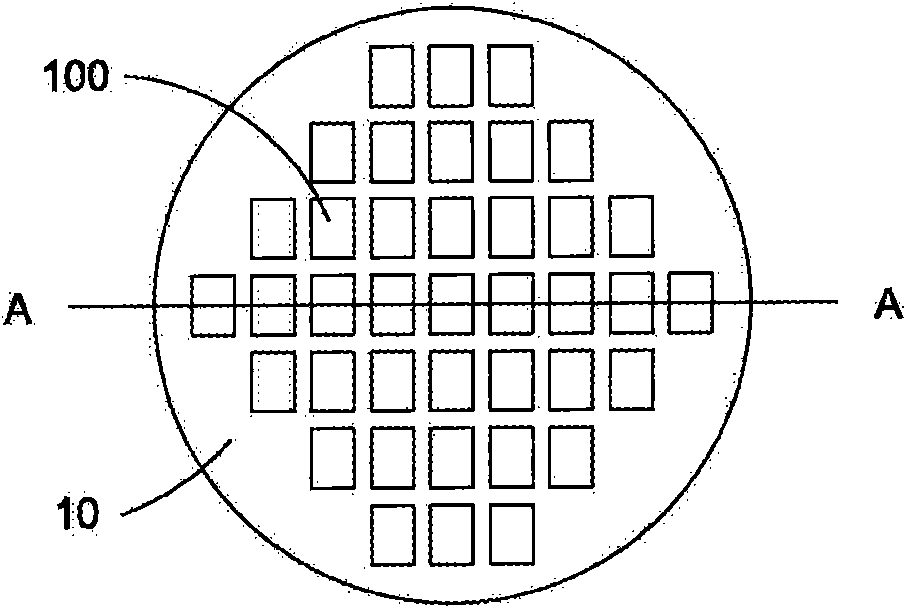

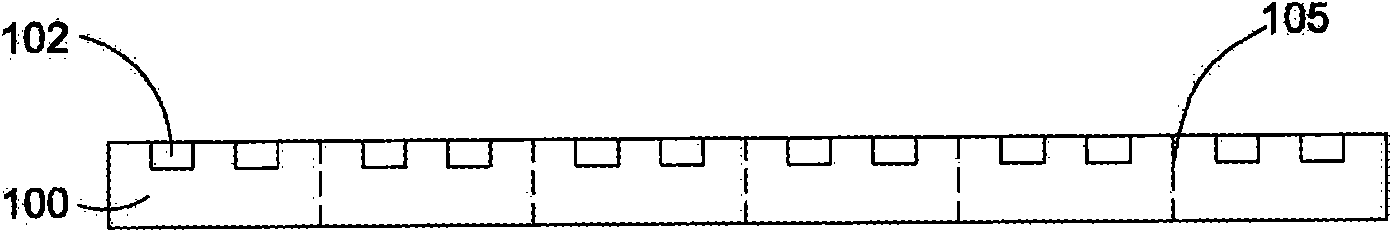

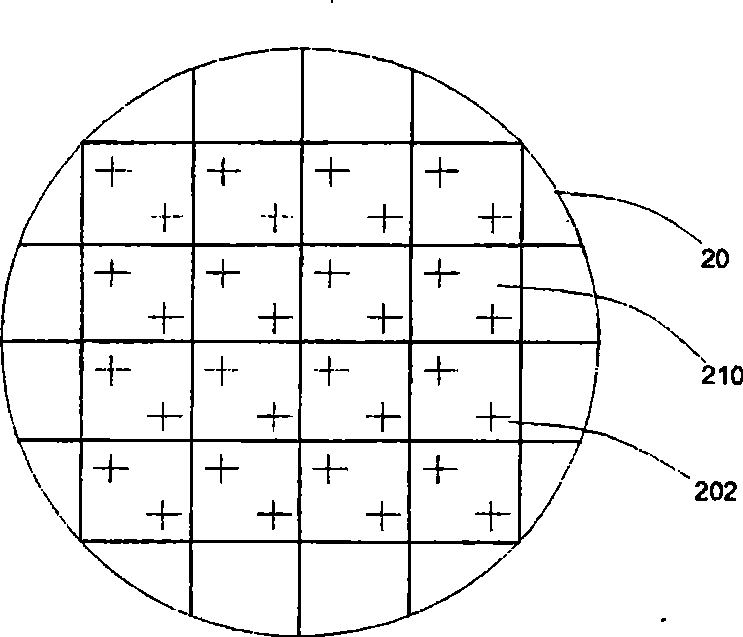

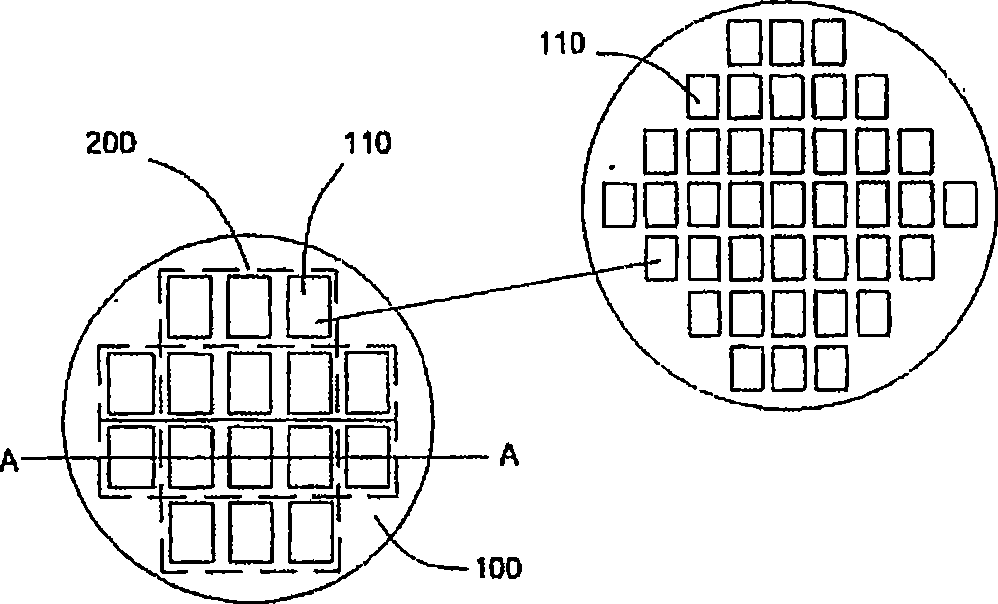

Crystal particle reconfigure encapsulation method

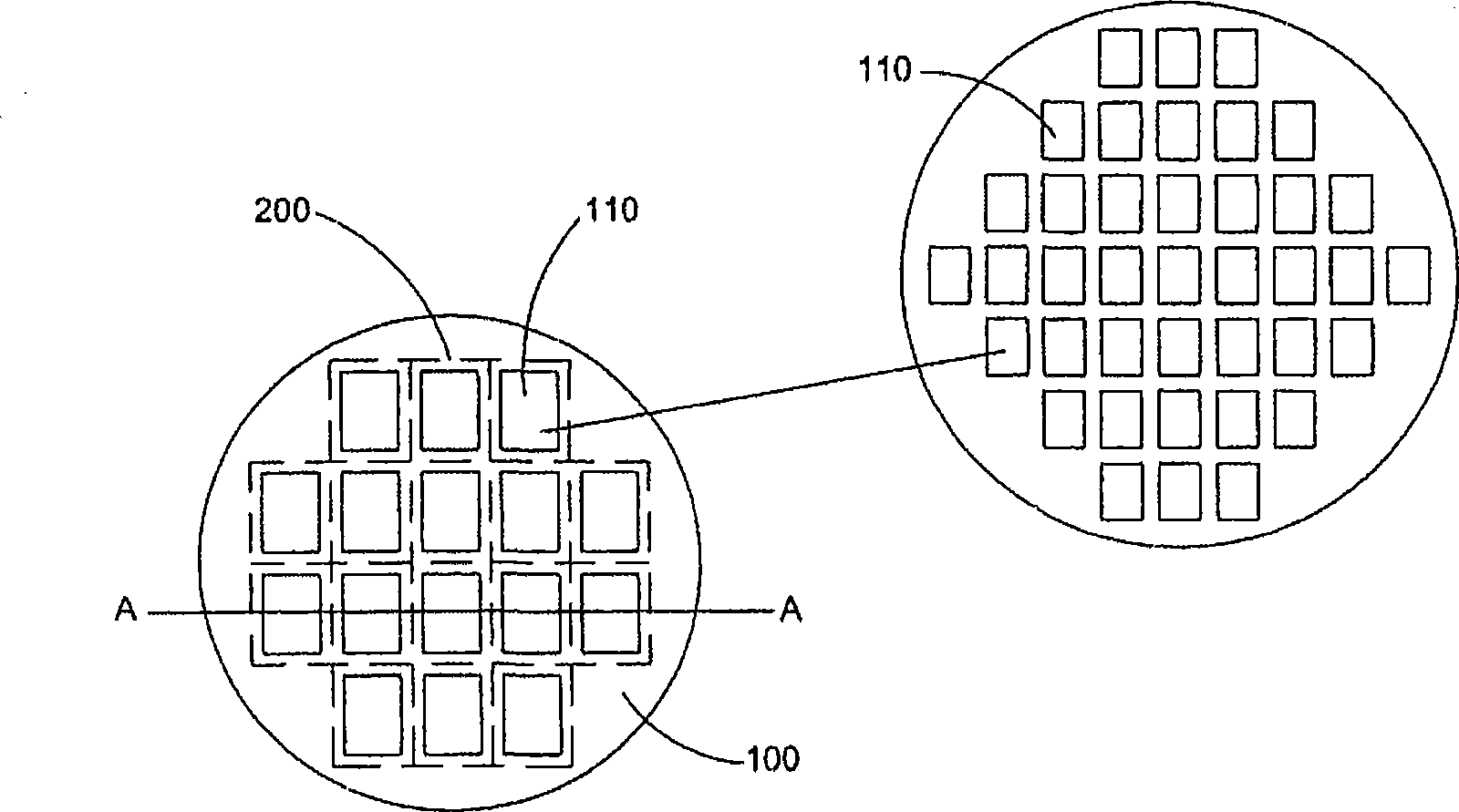

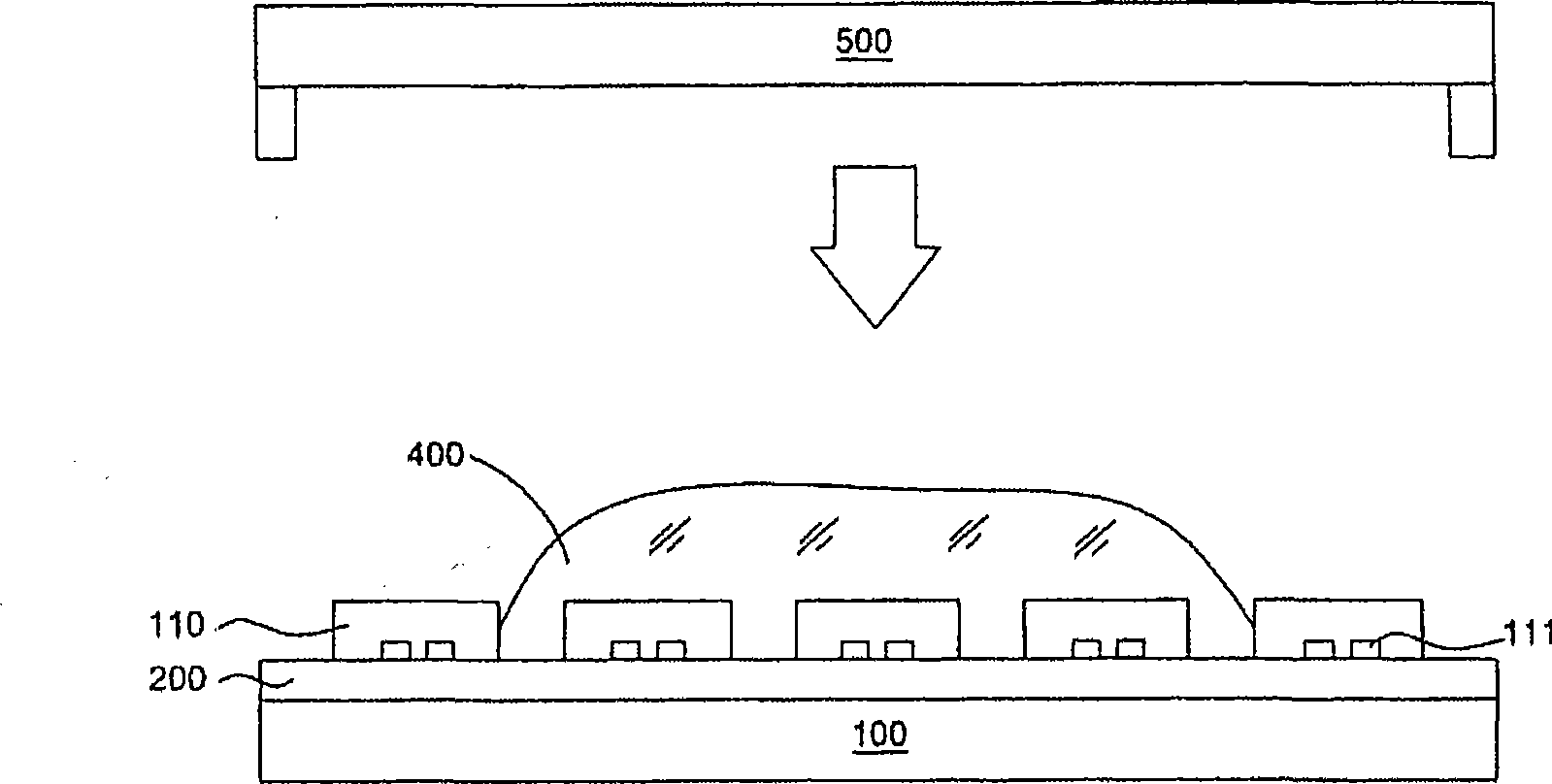

ActiveCN101399212AImprove yieldImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePolymer

An encapsulation method of reconfiguration of crystal grains comprises: a plurality of crystal grains are provided, and each of the crystal grains is provided with an active surface which is configured with a plurality of pads; the crystal grains are attached to a base plate, and each of the crystal grains connects the active surface and an adhesive layer configured on the base plate in a way of flip chip; polymer material is formed on the base plate and part of the crystal grains; and then, the polymer material is covered with the a die device in order to lead the polymer material to be flat, so that the polymer material is filled among the crystal grains and covers the crystal grains; after that, the polymer material is separated from the die device to lead the surface of the polymer material to be exposed; a plurality of scribe lines are formed on the exposed polymer material; at last, the polymer material is separated from the base plate to expose the active surface of each crystal grain, so that an encapsulation body is formed.

Owner:CHIPMOS TECH INC

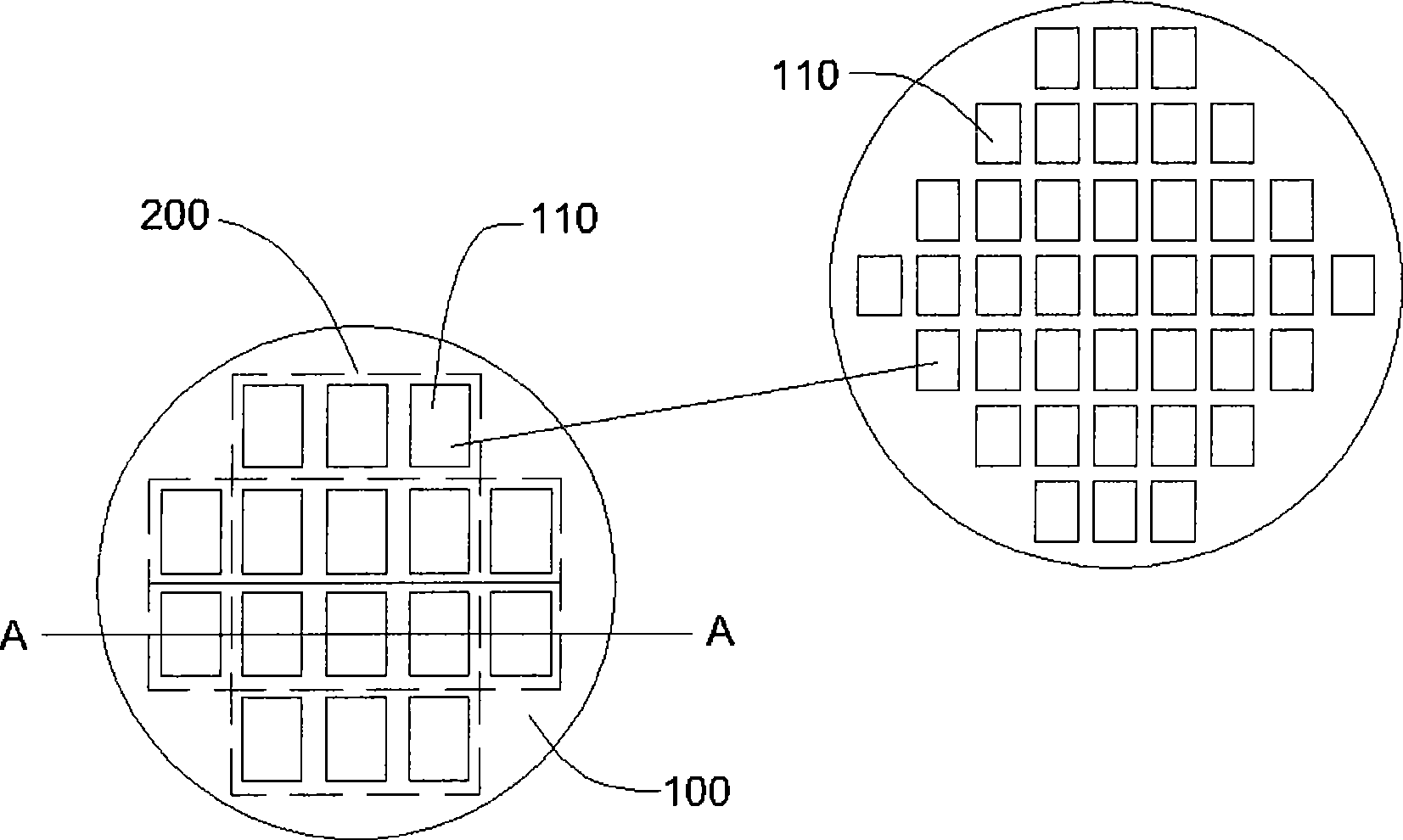

Encapsulation structure and encapsulation method for modularization crystal grains

ActiveCN101572237AReduce packaging costsLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

The invention relates to an encapsulation structure for modularization crystal grains, comprising a crystal grain accommodation bracket, an encapsulation body, a plurality of patterning first protection layers, a plurality of patterning metal line segments, a plurality of patterning second protection layers, a plurality of patterning UBM layers and a plurality of conductive elements, wherein the crystal grain accommodation bracket is provided with a plurality of crystal grain accommodation areas and a plurality of crystal grains, an active face of each crystal grain is provided with a plurality of welding disks, and the back face of each crystal grain is fixedly connected on the front faces of the crystal grain accommodation areas; the encapsulation body annually covers the crystal grain accommodation bracket with the plurality of crystal grains and the four faces of every crystal grain with the welding disks exposed; the patterning first protection layers covers the active faces of the crystal grains, with the welding disks exposed; one end of every patterning metal line segment is electrically connected with the welding disks, and the other end covers the surfaces of the first protection layers; the patterning second protection layers cover the metal line segments, parts of the surfaces of the fanning-out structures of the metal line segments are exposed, and the fanning-out structures are extended towards the exterior sides of the active faces of the crystal grains; the patterning UBM layers are formed on the surface of the fanning-out structure of every metal line segment, the fanning-out structure is extended towards the exterior side, and the patterning UBM layers are electrically connected with the metal line segments; and the conductive elements are electrically connected with the metal line segments by the UBM layers.

Owner:CHIPMOS TECH INC

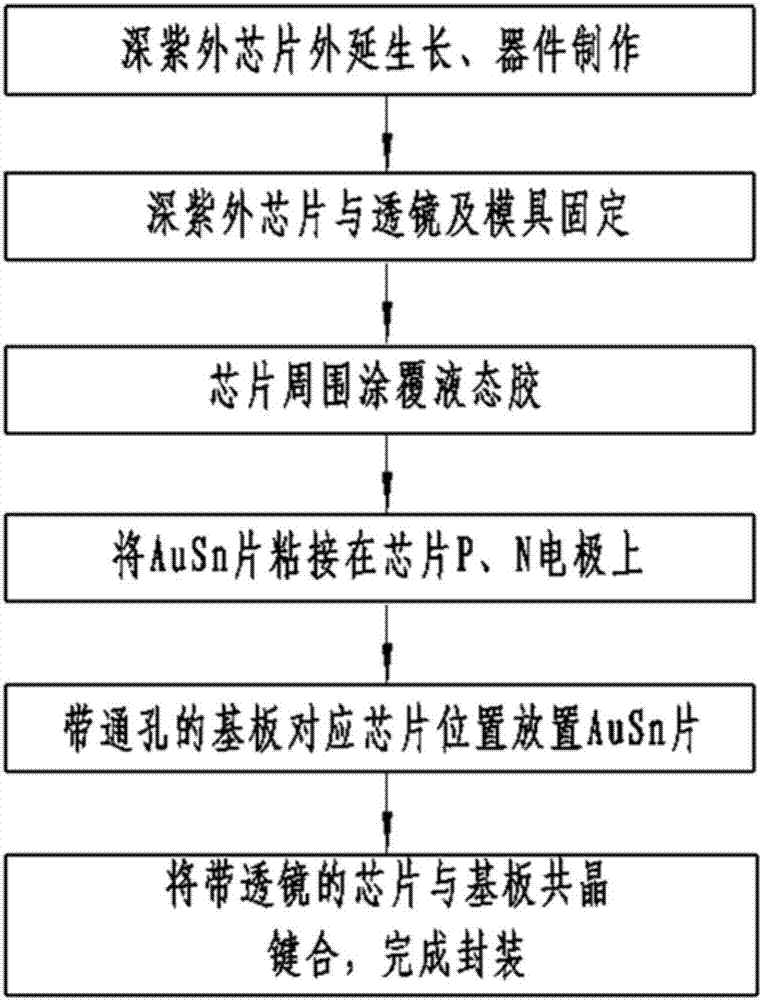

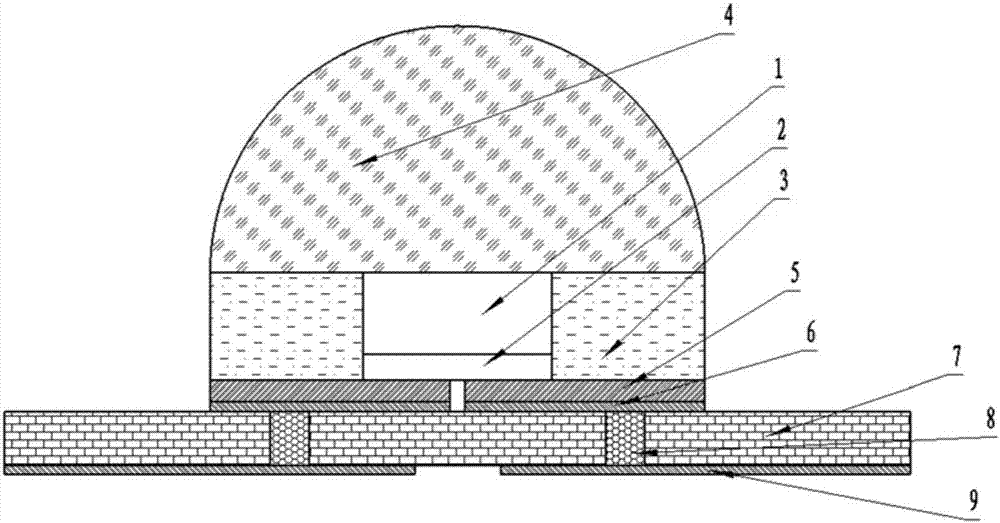

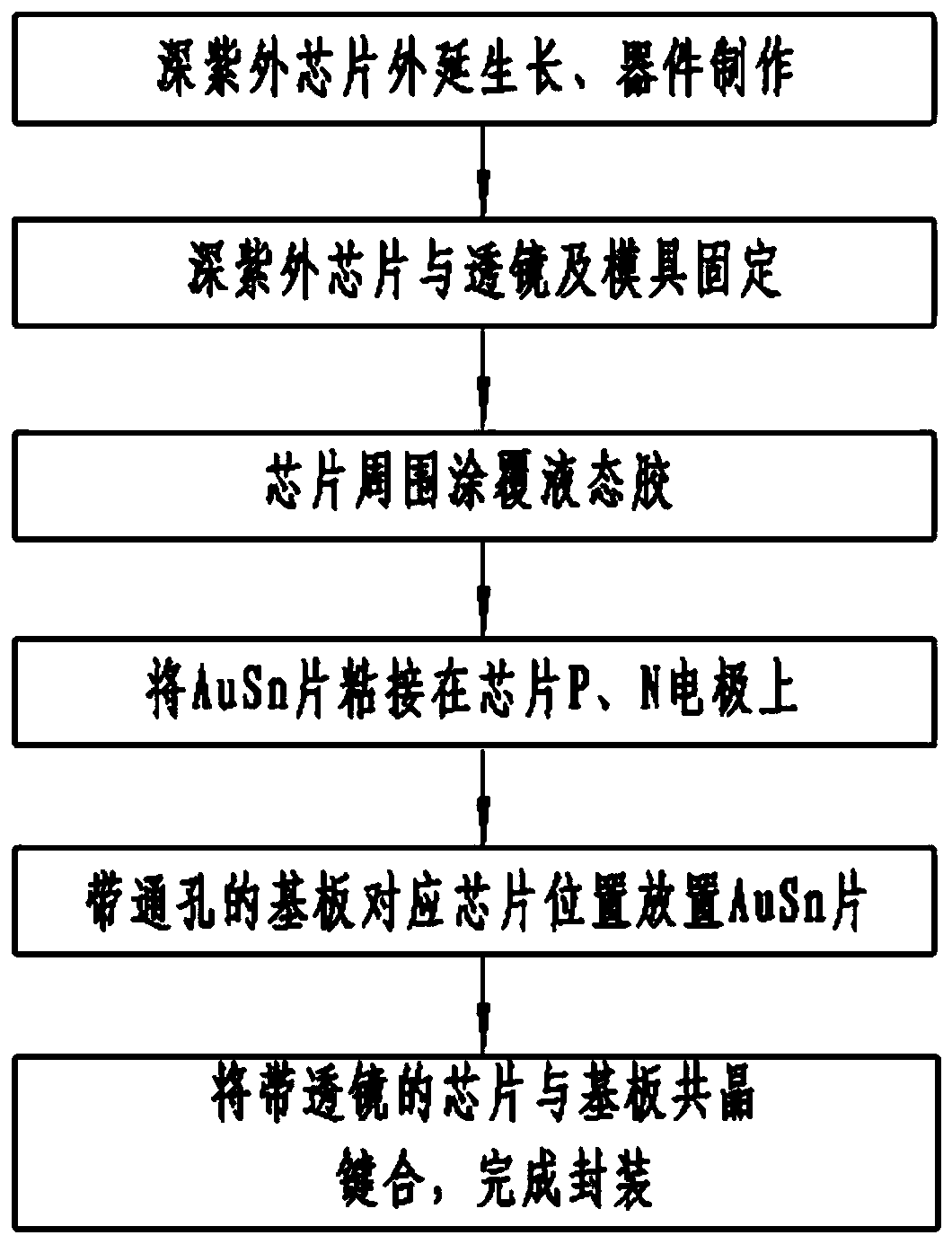

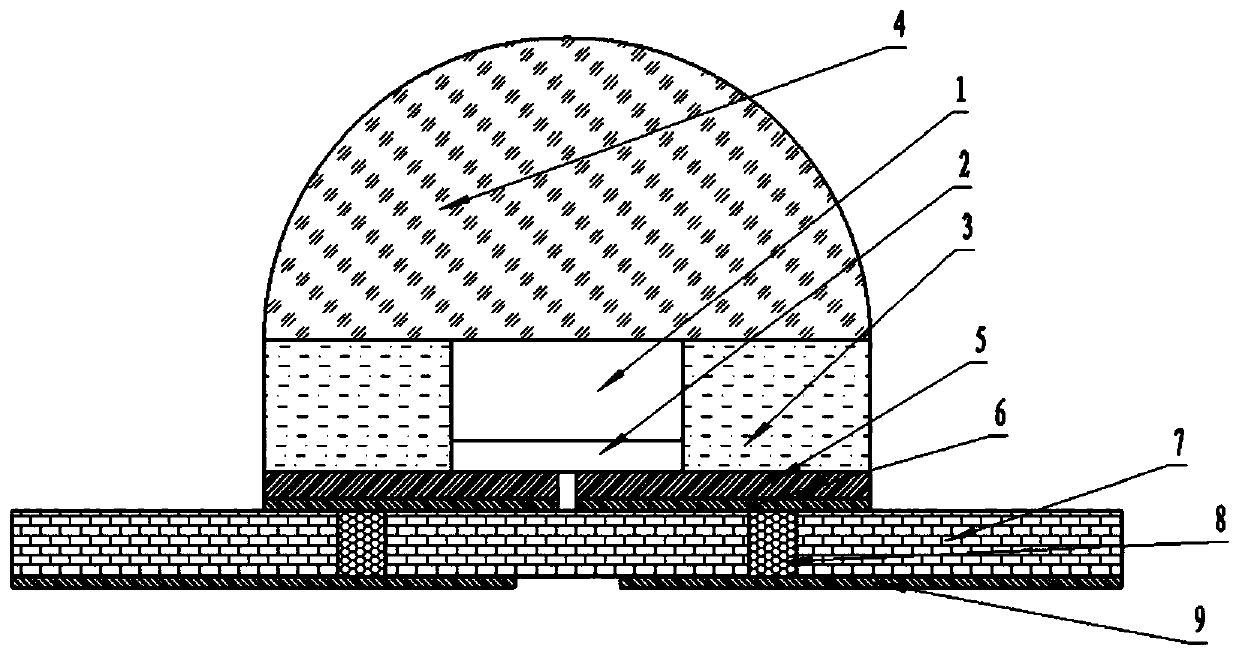

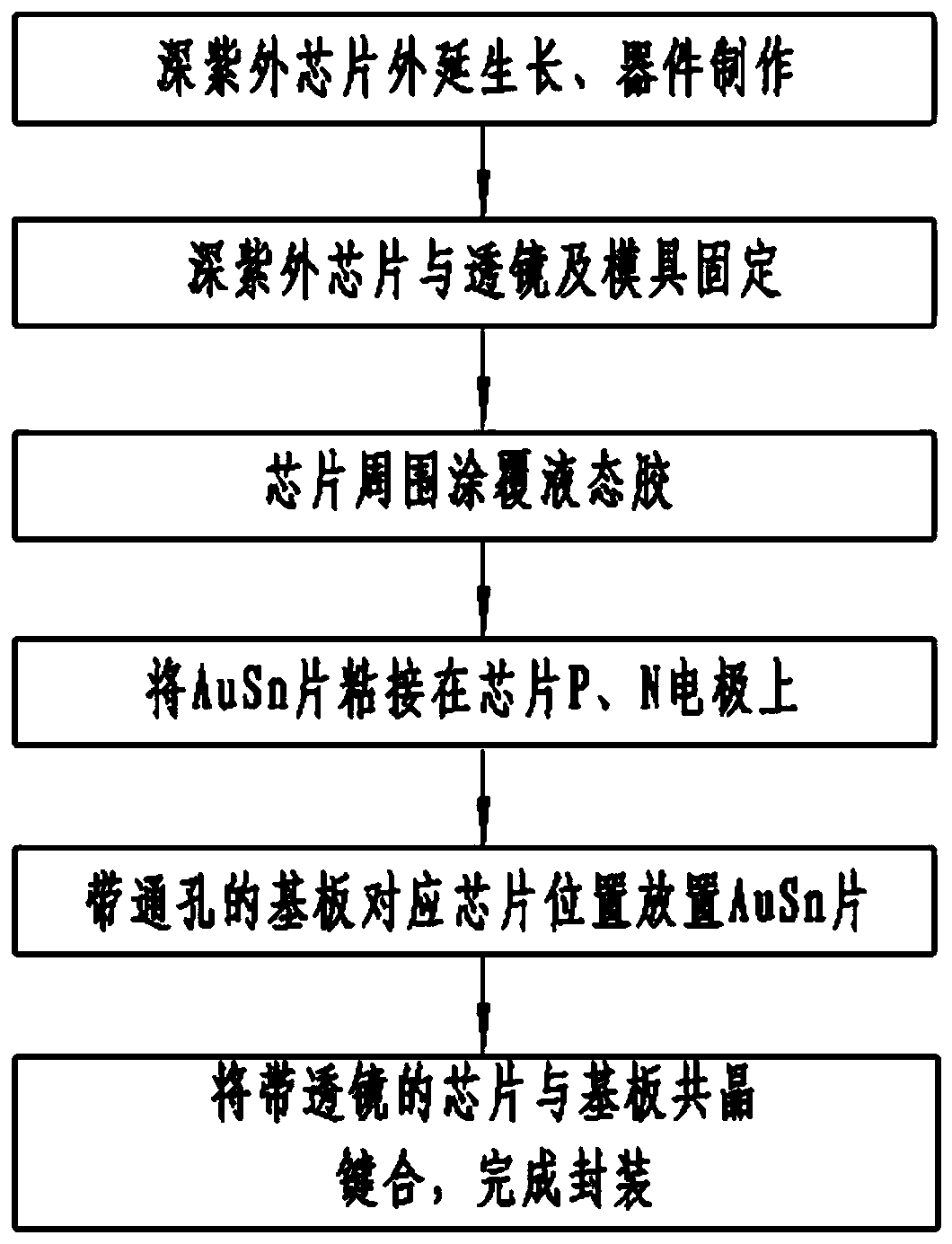

Chip sized deep ultraviolet light emitting diode eutectic packaging method

ActiveCN107256911AReduce package sizeReduce packaging costsSemiconductor devicesChip sizeUltraviolet light emitting diodes

The invention provides a chip sized deep ultraviolet light emitting diode eutectic packaging method. The method includes the steps of fixing a deep ultraviolet chip with separated P and N electrodes to a quartz lens; filling a liquid glue to the side surface of the deep ultraviolet chip to make the upper surface of the liquid glue be flushed with the P and N electrodes of the deep ultraviolet chip, and solidifying the liquid glue; fixing a first AuSn sheet above the P and N electrodes of the deep ultraviolet chip to cover the upper surface of the liquid glue, and reserving the isolation channel of the P and N electrodes; fixing a second AuSn sheet to a substrate, wherein the second AuSn sheet is aligned with the first AuSn sheet vertically; and performing the eutectic fusion of the first AuSn sheet and the second AuSn sheet to complete the packaging. The chip size technology is applied to the deep ultraviolet LED packaging, so that the packaging efficiency is improved, the packaging cost is reduced, the cooling problem of the deep ultraviolet LED chip is solved by the eutectic packaging technology, and the service life of the deep ultraviolet LED can be prolonged.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

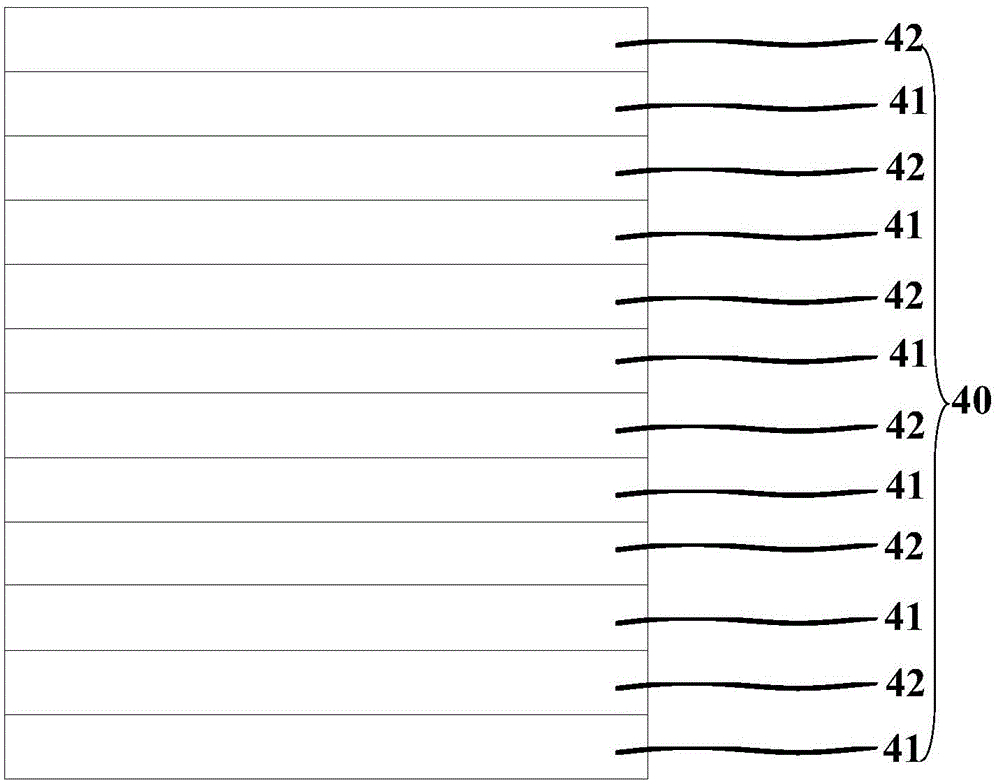

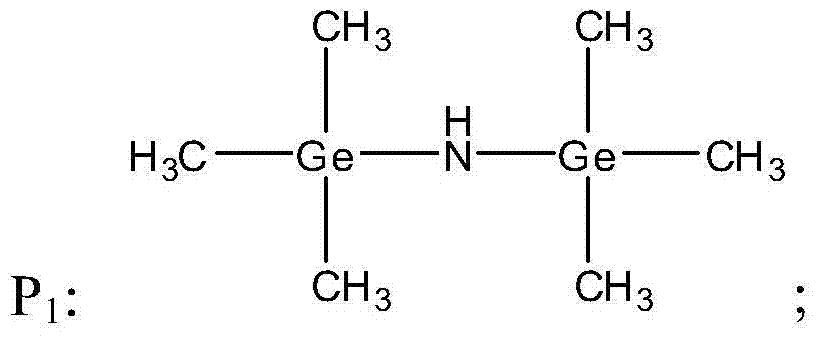

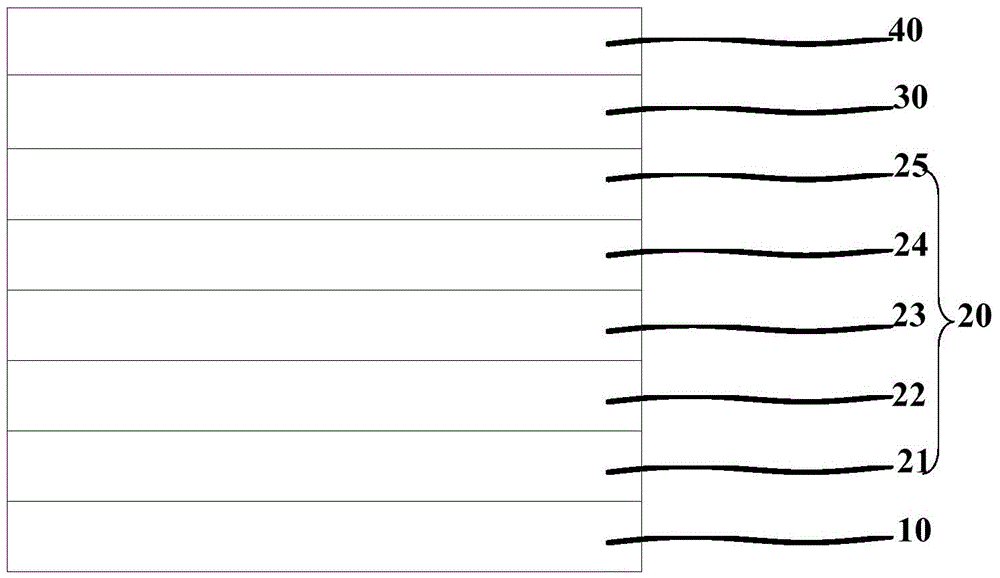

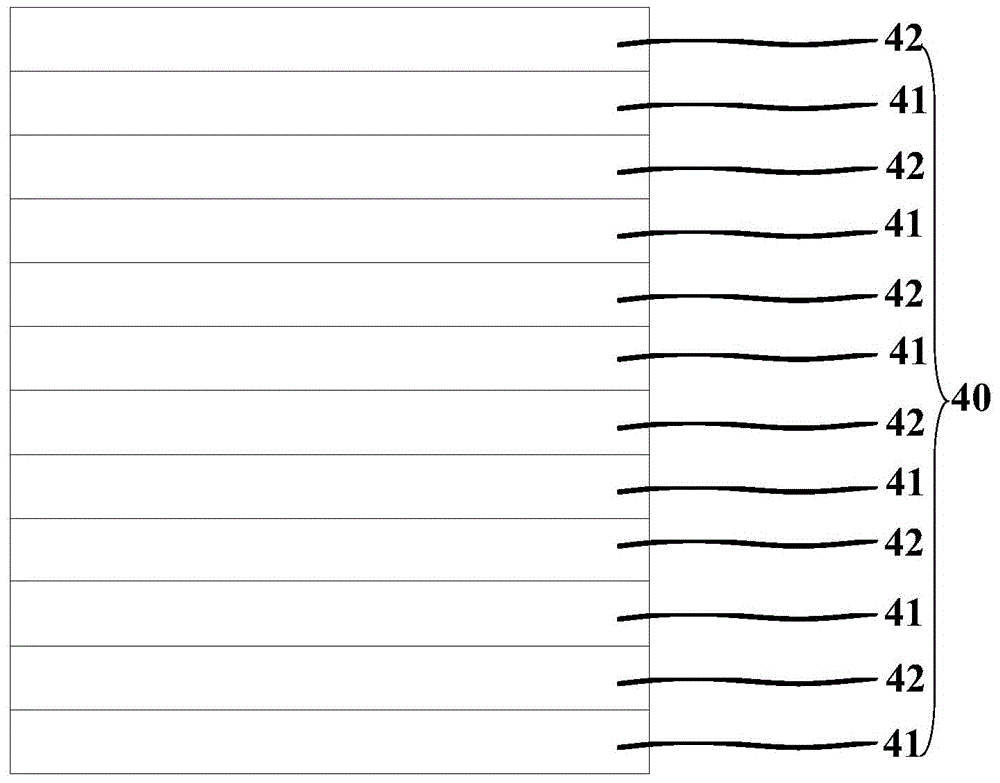

Organic light-emitting device and preparation method thereof

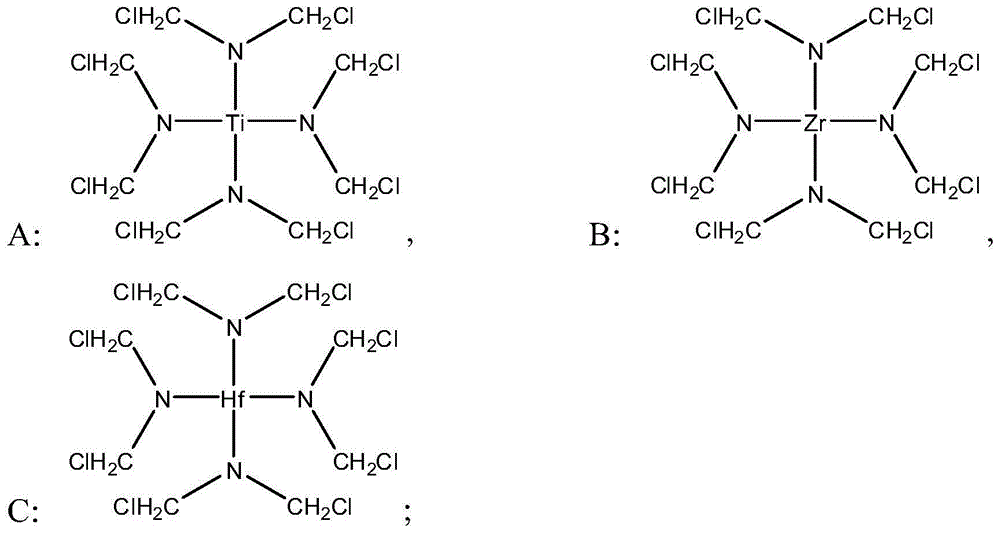

InactiveCN104638117APrecise thickness controlPrecise control of ingredientsSolid-state devicesSemiconductor/solid-state device manufacturingCarbon numberOrganic light emitting device

The invention provides an organic light-emitting device. The organic light-emitting device comprises an anode conductive substrate, an organic light-emitting functional layer, a cathode and a packaging layer in sequentially overlapped arrangement. The packaging layer comprises inorganic barrier layers and organic barrier layers, and the inorganic barrier layers and the organic barrier layers are sequentially overlapped on the surface of the cathode. The inorganic barrier layers are made of TiO2:Cl, ZrO2:Cl or HfO2:Cl. The organic barrier layers are made of loop-chain borane with a structural formula shown in the original text, wherein R1 refers to same or different naphthene bases, branched alkyls or straight-chain alkyls with carbon number being 1-6, l refers to an integer ranging from 1 to 10, m refers to an integer ranging from 5 to 15, and n refers to an integer ranging from 0 to m-1. The packaging layer is high in compactness, so that service lives of devices, especially flexible devices, can be prolonged to be longer than 11500 hours (T701000cd / m<2>). The invention further provides a preparation method of the organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Modulated multi-die package construction and method thereof

ActiveCN101488462AGuaranteed smoothImprove yieldSemiconductor/solid-state device detailsSolid-state devicesLine segmentBiomedical engineering

The invention relates to a modularized multi-crystal grain encapsulating structure, comprising; a plurality of crystal grains, an encapsulated body, a plurality of patterned metal line sections, a patterned protective layer, a plurality of conductive components and a heat radiator, wherein, each of the crystal grains is provided with an active surface on which a plurality of weld pads are provided; the encapsulated body circles and covers five surfaces of each crystal grain and exposes the active surface and each weld pad of each crystal grain; two ends of part of the patterned metal line sections are electrically connected with a plurality of weld pads on the active surfaces of the crystal grains, while one end of part of the patterned metal line sections are electrically connected with a plurality of weld pads on the active surfaces of the crystal grains; the patterned protective layer covers a plurality of patterned metal line sections and exposes the other ends of part of the patterned metal line sections; the conductive components are electrically connected with the other end of each exposed patterned metal line section and the heat radiator is formed at the back of the encapsulated body.

Owner:CHIPMOS TECH INC

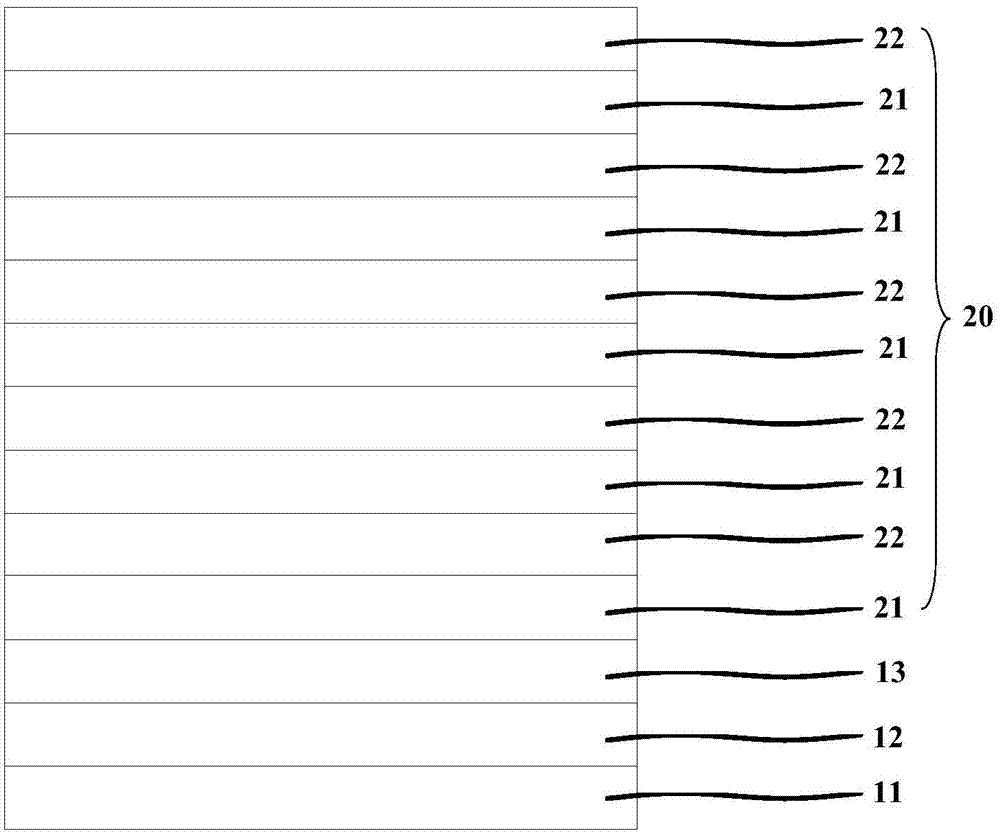

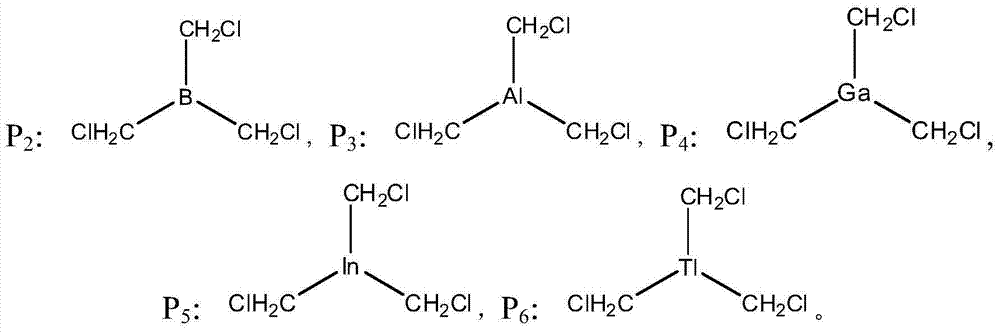

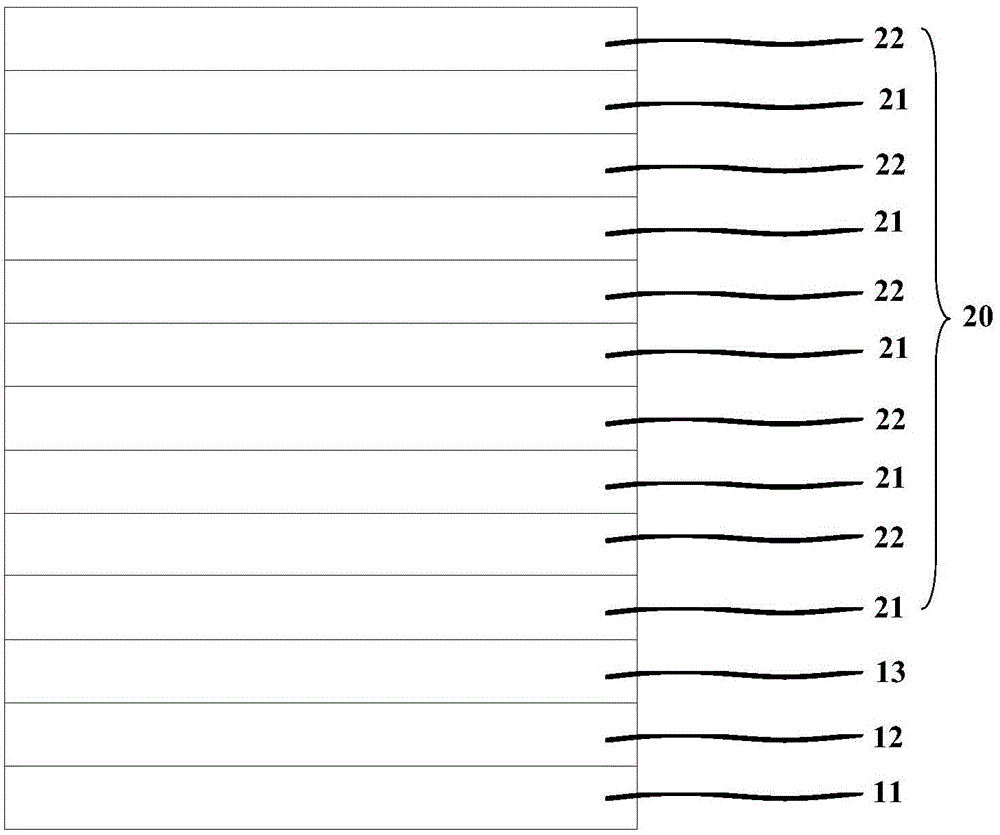

Encapsulation structure and encapsulation method of organic light emitting diode device

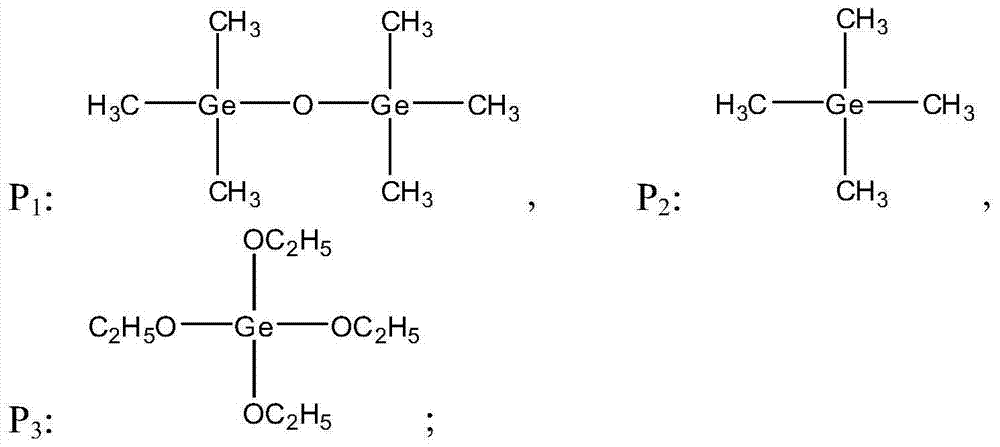

InactiveCN104518157ALow deposition temperatureSmall structureSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsHigh density

The invention discloses an encapsulation structure of an organic light emitting diode device. The encapsulation structure includes an anode electric conduction substrate as well as an organic light-emitting functional layer, a cathode and a thin film encapsulation layer which are sequentially stacked on the anode electric conduction substrate, wherein the thin film encapsulation layer includes germanium oxynitride film layers and inorganic barrier layers which are sequentially stacked on the cathode, wherein the germanium oxynitride film layers are made of a germanium oxynitride compound, and the inorganic barrier layers are made of B2O3:Cl, Al2O3:Cl, Ga2O3:Cl, In2O3:Cl or Tl2O3:Cl. The thin film encapsulation layer in the encapsulation structure of the invention has very high density, and therefore, with the encapsulation structure adopted, erosion of organic compounds and electrodes in the organic light emitting diode device which is caused by matters such as oxygen and water vapor can be effectively reduced, and therefore, the service life of the device, especially a flexible device can be prolonged, the service life of the device can reach more than 13700 hours (T70@1000cd / m<2>). The invention also provides an encapsulation method of an organic light emitting diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

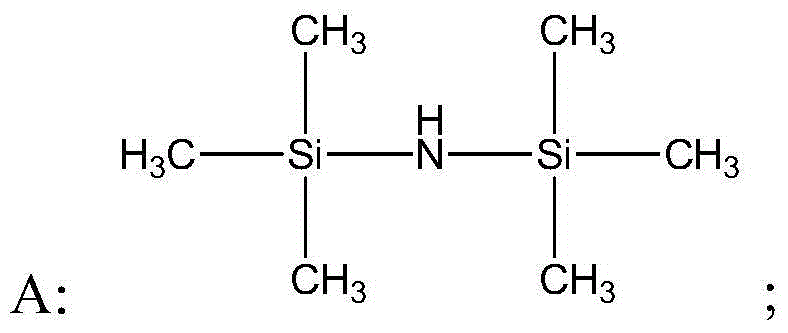

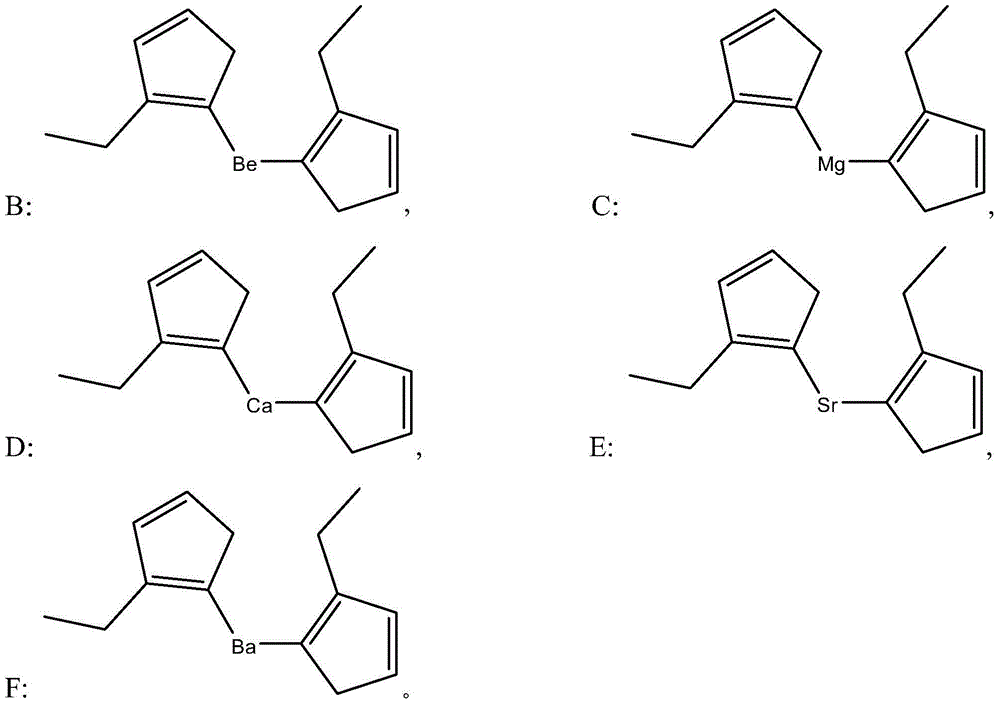

Organic electroluminescent device and production method thereof

InactiveCN104638163ALow deposition temperatureSmall structureSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsOptoelectronics

The invention discloses an organic electroluminescent device comprising an anodic conductive substrate, an organic luminescent function layer, a cathode and a sealing layer. The organic luminescent function layer, the cathode and the sealing layer are stacked in order on the cathodic conductive substrate. The sealing layer comprises a silicon oxynitride film layer and an inorganic barrier layer stacked in order on the surface of the cathode; the silicon oxynitride film layer is made of silicon oxynitride; the inorganic barrier layer is made of beryllium oxide, beryllium oxide, calcium oxide, strontium oxide or barium oxide. The sealing layer is highly compact, erosion of organic compounds and the electrode in the organic electroluminescent device by matters such as oxygen and water is effectively decreased; life of a device, especially a flexible device, is prolonged to 15000 hours and above (T70@1000cd / m<2>); the invention further provides a production method of the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Chip stacking structure forming method

ActiveCN101615583BReduce packaging costsSave packaging materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringSoldering

The invention relates to a chip packaging structure and a forming method thereof. The packaging structure comprises a chip, a packaging body, a first patterned protection layer, a metal layer, a second patterned protection layer, a plurality of patterned UBM layers and a plurality of conductive assemblies, wherein a plurality of soldering pads and adhesion layers are respectively arranged on an active surface and a back surface of the chip; the packaging body is annularly covered on four surfaces of the chip so as to expose the soldering pads of the chip out and is provided with a plurality of through holes; the first patterned protection layer is formed on the partial surface of the packaging body and the active surface of the partial chip and exposes the soldering pads and the through holes out; the metal layer is covered on the partial surface of the first patterned protection layer, and is electrically connected with the soldering pads and filled in the through holes; the second patterned protection layer is covered on the first patterned protection layer and a part of metal layer and exposes the partial surface of the metal layer out; the patterned UBM layers are formed on the partial surface of the exposed metal layer and the partial surface of the second patterned protection layer and are electrically connected with the metal layer; and the conductive assemblies are formed on the patterned UBM layers and electrically connected with the metal layer through the patterned UBM layers.

Owner:CHIPMOS TECH INC

Stacked chip packaging structure based on special-shaped resin gasket

PendingCN108987381AHigh densitySmall sizeSemiconductor/solid-state device detailsSolid-state devicesEngineeringPolyresin

The invention relates to a stacked chip packaging structure based on a special-shaped resin gasket, comprises a circuit board, a first adhesive layer, a profiled resin gasket, a second adhesive layer,a first chip and an encapsulating material, wherein the first adhesive layer, the profiled resin gasket and the second adhesive layer are encapsulated on the circuit board with the encapsulating material, and the first chip is electrically connected with the circuit board through bonding wires; At least one cavity is arranged in that middle of the shaped resin pad, and at least one second chip isarranged in the cavity, and the second chip is electrically connected with the circuit board through bonding wires. The stacked chip packaging structure of the invention can reduce the size of the chip packaging structure, save the packaging material, and improve the density of the chip in the unit area.

Owner:SU ZHOU DREAM TECH CO LTD

Multi-chip stacked package structure and packaging method thereof

ActiveCN107680951AImprove performanceSimple processSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionConduction loss

The present invention relates to a multi-chip stacked package structure and a packaging method thereof. According to the multi-chip stacked package structure and the packaging method thereof, only oneconnection sheet is disposed on the source of an HS chip and the drain of an LS chip to achieve the electrical connection of the HS chip and the LS chip, the conduction loss and switching loss of thepackage structure are reduced, and the heat dissipation efficiency of the package structure is enhanced; an IC chip is connected with the connection sheet in an insulated manner, and therefore, the IC chip can be stacked above a plane where the HS chip and the LS chip are located, and therefore, the size of a packaged device can be effectively decreased; the bottom surfaces of a first chip carrying stage and a second chip carrying stage can be exposed outside a package body; optionally, a part of the surface of a portion of the connection sheet which is not connected with the IC chip is exposed outside the package body; optionally, a heat dissipation plate is connected onto the connection sheet, and a part of the surface of the heat dissipation plate is exposed outside the package body; and optionally, the heat dissipation plate is inserted into a gap reserved in the package body so as to contact with the connection sheet to facilitate heat dissipation.

Owner:ALPHA & OMEGA SEMICON INT LP

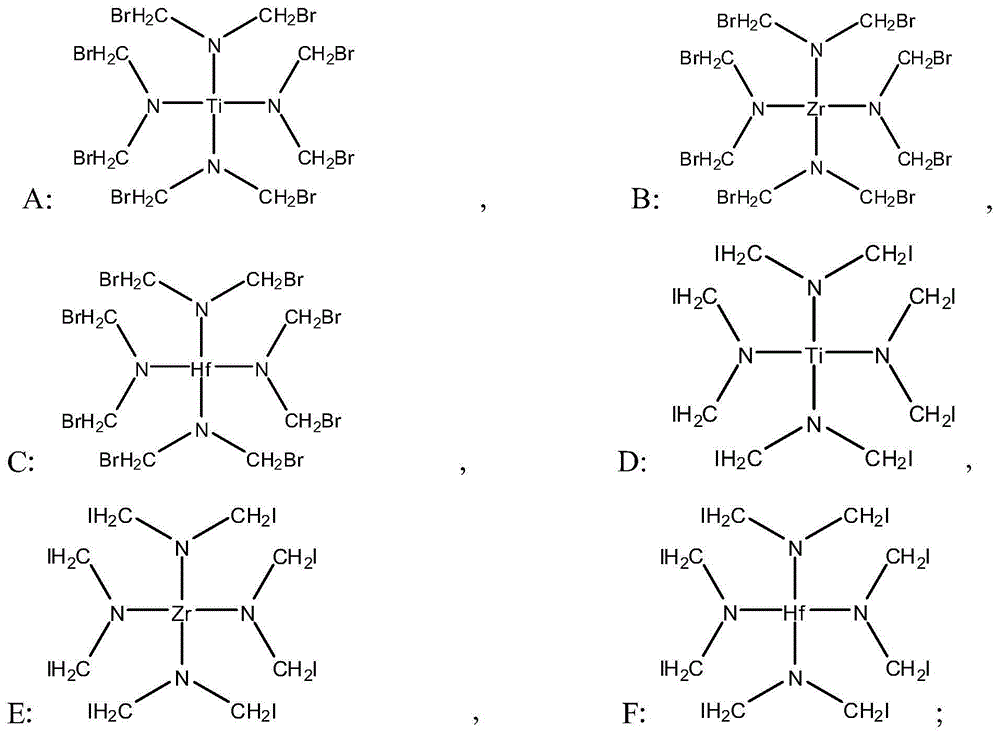

Organic electroluminescent device and preparation method thereof

InactiveCN104882548AFacilitate flexible packagingEnable flexible packagingSolid-state devicesSemiconductor/solid-state device manufacturingTitanium nitrideBoron nitride

The invention discloses an organic electroluminescent device which comprises the components of an anode conductive substrate, an organic light emitting functional layer, a cathode and a packaging layer; wherein the organic light emitting functional layer, the cathode and the packaging layer are successively laminated on the anode conductive substrate. The packaging layer comprises a first inorganic barrier layer and a second inorganic barrier layer which are successively laminated on the surface of the cathode. The first inorganic barrier layer is made of bromine-doped titanium oxide, bromine-doped zirconia, iodine-doped titanium oxide, iodine-doped zirconia or iodine-doped hafnium oxide. The second inorganic barrier layer is made of silicon oxide, alumina, titanium oxide, zirconia, hafnium oxide, tantalum oxide, silicon nitride, aluminum nitride, boron nitride, vanadium nitride, tantalum nitride or titanium nitride. The packaging layer of the invention has high compactness, thereby prolonging service life of the organic electroluminescent device, particularly a flexible organic electroluminescent device. The invention further provides a preparation method for the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

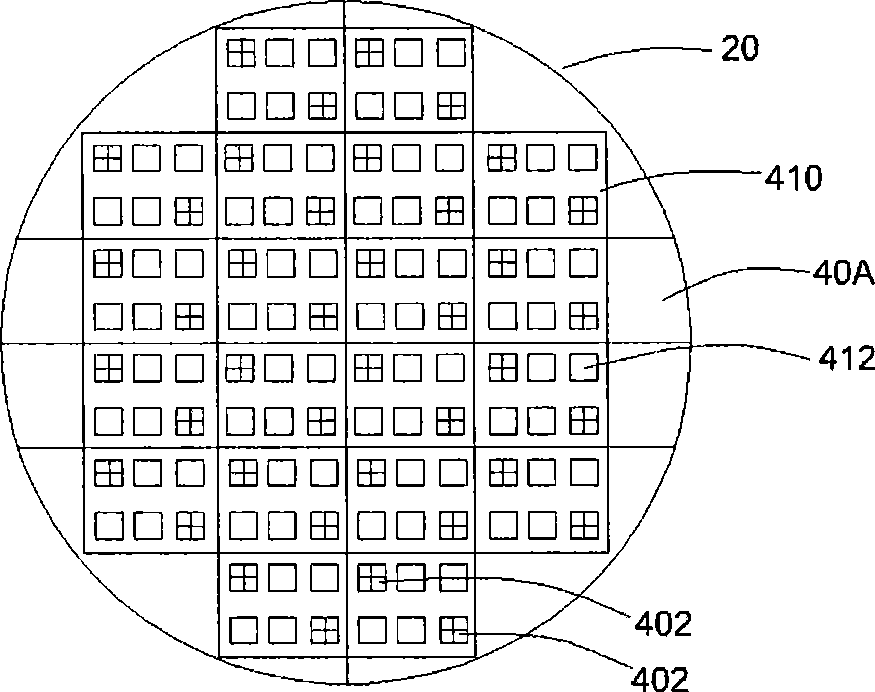

Manufacturing method for using compliant layer in grain reconfigured encapsulation construction

ActiveCN101452863AReduce packaging costsSave packaging materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringBlock structure

The invention relates to an encapsulation structure for reconfiguring crystal grains. The encapsulation structure comprises a crystal grain, an encapsulating body, a plurality of protrudent block structures, a plurality of patternized metal wire sections and a protective layer, wherein one active surface of the crystal grain is provided with a plurality of welding pads; the encapsulating body covers five sides of the crystal grain; the plurality of the protrudent block structures are formed from a macromelocular material and are arranged on the active surface of the crystal grain in an array mode; one end of each patternized metal wire section is in electric connection with the plurality of the welding pads on the active surface of the crystal grain; the other end of each patternized metal wire section extends and covers each protrudent block structure; and the protective layer is used for covering each patternized metal wire section and part of a patternized macromolecular material layer and exposing the protrudent block and the patternized metal wire section covered on the protrudent block structure.

Owner:CHIPMOS TECH INC

Chip size level deep ultraviolet light emitting diode eutectic packaging method

ActiveCN107256911BReduce package sizeReduce packaging costsSemiconductor devicesChip sizeUltraviolet light emitting diodes

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Encapsulation structure and encapsulation method of organic light emitting diode device

InactiveCN104518159ALow deposition temperatureSmall structureSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceLight-emitting diode

The invention discloses an encapsulation structure of an organic light emitting diode device. The encapsulation structure includes an anode electric conduction substrate as well as an organic light-emitting functional layer, a cathode and a thin film encapsulation layer which are sequentially stacked on the anode electric conduction substrate, wherein the thin film encapsulation layer includes germanium oxycarbide film layers and inorganic barrier layers which are sequentially stacked on the cathode, wherein the germanium oxycarbide film layers are made of a germanium oxycarbide compound, and the inorganic barrier layers are made of B2O3:Cl, Al2O3:Cl, Ga2O3:Cl, In2O3:Cl or Tl2O3:Cl. The thin film encapsulation layer in the encapsulation structure of the invention has very high density, and therefore, with the thin film encapsulation layer adopted, erosion of organic compounds and electrodes in the organic light emitting diode device which is caused by matters such as oxygen and water vapor can be effectively reduced, and therefore, the service life of the device, especially a flexible device can be prolonged, the service life of the device can reach more than 13900 hours (T70@1000cd / m<2>). The invention also provides an encapsulation method of an organic light emitting diode device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for manufacturing package structure with reconfigured crystal particle by net-shaped structure

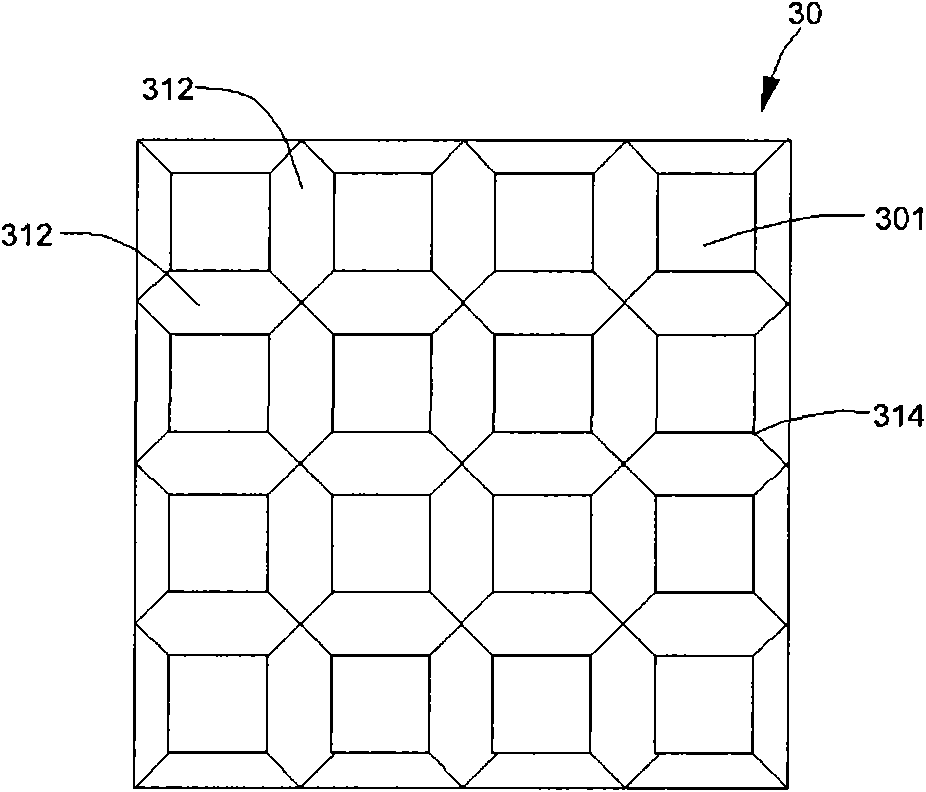

ActiveCN101436552ALow costSave packaging materialSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention relates to an encapsulating structure for rearrangement of a crystal grain, which comprises the crystal grain which is provided with an active surface and a lower surface and is provided with plurality of welding pads on the active surface, an encapsulating body, a plurality of fan-out metal segments, a protective layer and a plurality of conductive components, wherein the encapsulating body is used for wrapping five surfaces of the crystal grain and exposing the plurality of the welding pads on the active surface of the crystal grain, one end of each of the plurality of the fan-out metal segments is electrically connected with the plurality of the welding pads, the protective layer is used for covering the active surface of the crystal grain and the plurality of the metal segments and exposing the upper surface at the other end of each metal segment, and the plurality of the conductive components are electrically connected with the other ends of the plurality of the metal segments.

Owner:CHIPMOS TECH INC

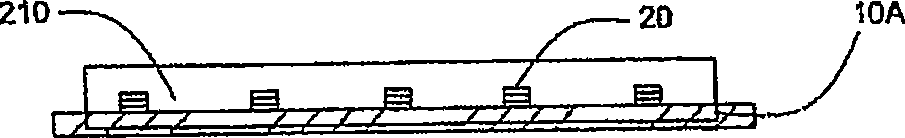

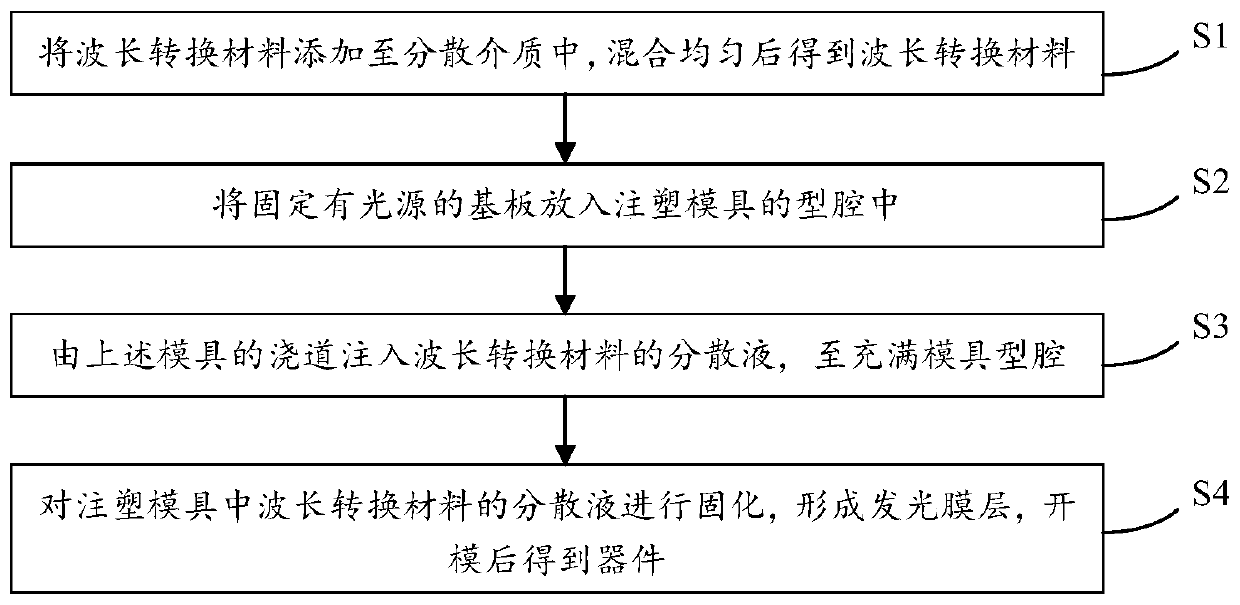

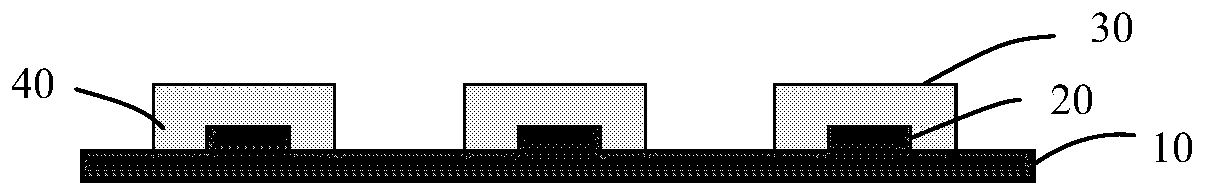

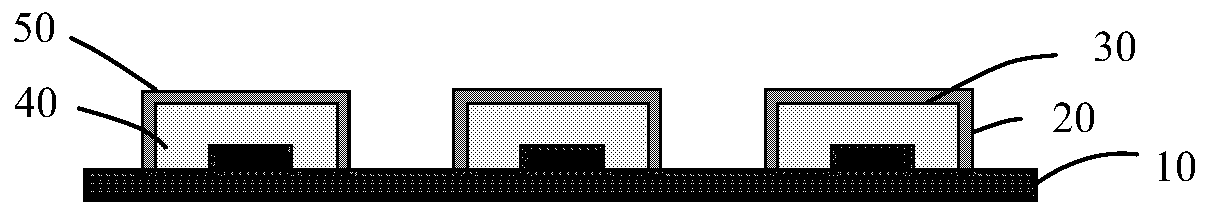

Preparation method of quantum dot light-emitting device and product thereof

InactiveCN110120444AAvoid damageImprove luminescence stabilitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotLight emitting device

The invention discloses a preparation method of a quantum dot light-emitting device and a product thereof. The preparation method comprises the following steps: adding a wavelength conversion materialinto a dispersion medium, and performing uniform mixing to obtain dispersion liquid of the wavelength conversion material; putting a substrate on which a light source is fixed into a cavity of an injection mold; injecting the dispersion liquid of the wavelength conversion material from a pouring gate of the mold until the mold cavity is filled with the dispersion liquid; and curing the dispersionliquid of the wavelength conversion material in the injection mold to form a light-emitting film layer, and opening the mold to obtain the device. According to the invention, the quantum dot light-emitting device prepared by the method improves the light-emitting stability.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com