Organic light-emitting device and preparation method thereof

An electroluminescent device, electroluminescent technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of heavy device, loss of absorption ability of desiccant, easy to produce cracks, etc., to achieve continuous and dense Thin film, good step coverage and large area thickness uniformity, the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

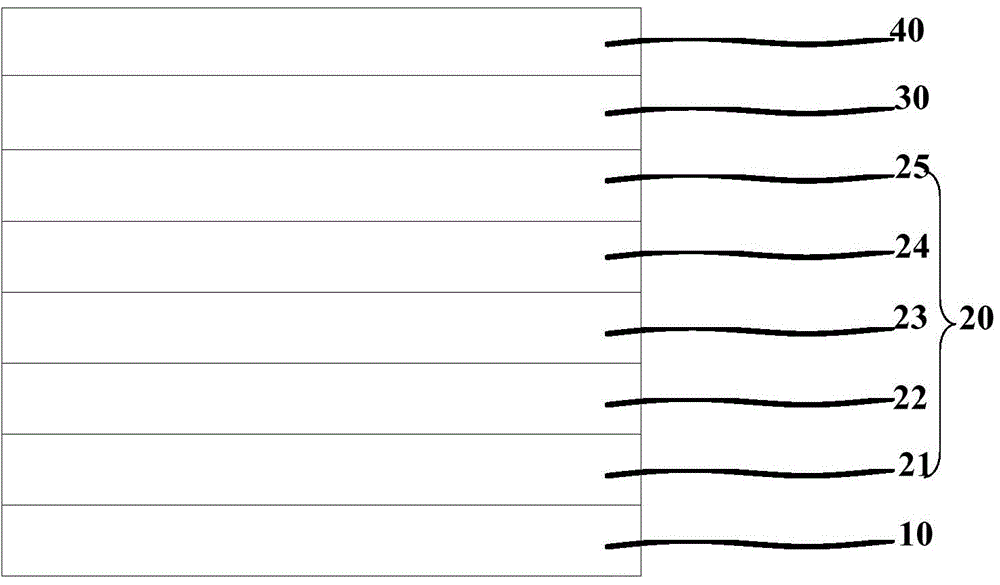

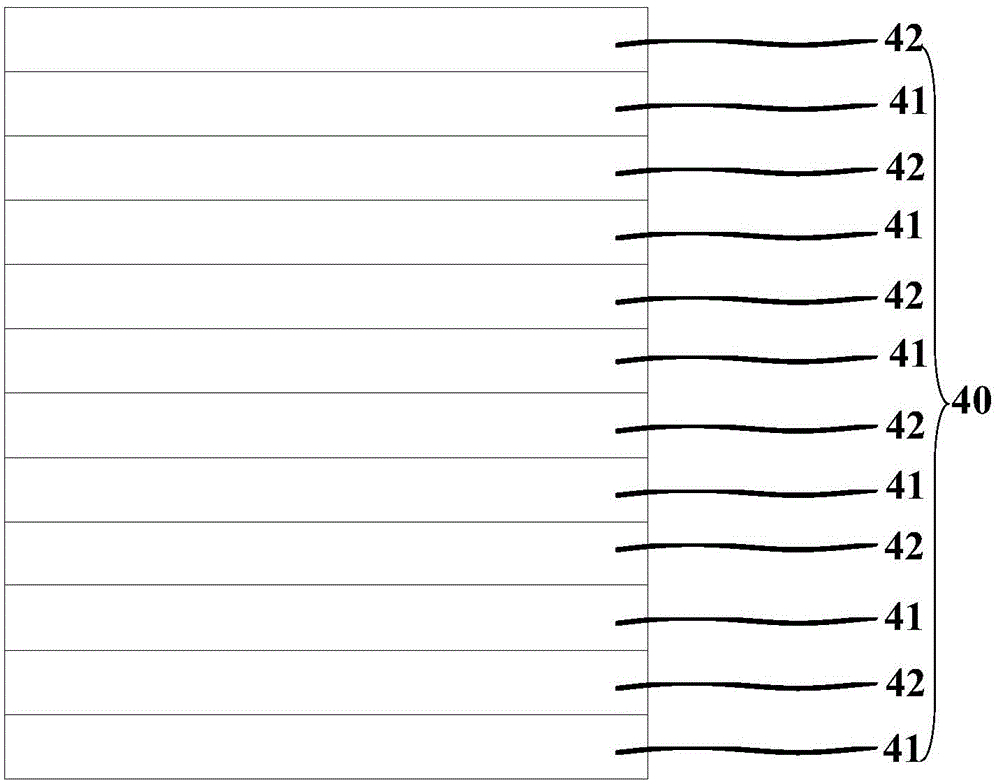

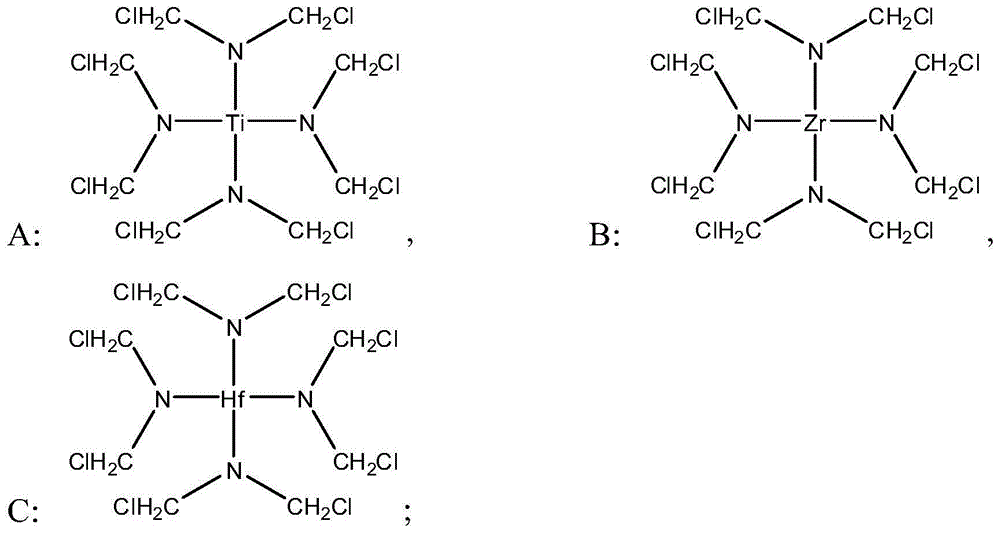

[0054] figure 1 It is the schematic diagram of the organic electroluminescence device in embodiment 1; As figure 1 As shown, the organic electroluminescent device includes an ITO glass substrate (10), an organic light-emitting functional layer (20), a cathode (30) and an encapsulation layer (40) stacked sequentially from bottom to top; wherein the organic electroluminescent function The layer (20) includes a hole injection layer (21), a hole transport layer (22), a light emitting layer (23), an electron transport layer (24) and an electron injection layer (25) stacked in sequence from bottom to top. figure 2 yes figure 1 Schematic diagram of the structure of the encapsulation layer; such as figure 2 As shown, the encapsulation layer (40) includes an inorganic barrier layer (41) and an organic barrier layer (42) sequentially stacked on the surface of the cathode (30); more specifically, the inorganic barrier layer is first deposited on the surface of the cathode (30) (41),...

Embodiment 2

[0071] A method for preparing an organic electroluminescent device, comprising the steps of:

[0072] (1), (2), (3) are the same as embodiment 1;

[0073] (4) Preparation of encapsulation layer:

[0074] a) Preparation of inorganic barrier layer: The inorganic barrier layer was prepared on the surface of the cathode by atomic layer deposition (ALD), the working pressure was 50Pa, and the deposition temperature was 60°C; the material was chlorine-doped zirconia (ZrO 2 :Cl), the precursor used in the process of depositing the inorganic barrier layer is tetrakis(dichloromethylamino)zirconium[Zr(N(CH 2 Cl) 2 ) 4 ] and water vapor, tetrakis(dichloromethylamino)zirconium[Zr(N(CH 2 Cl) 2 ) 4 ] injection time is 1s, water vapor injection time is 40ms, and nitrogen gas (N 2 ), tetrakis(dichloromethylamino)zirconium[Zr(N(CH 2 Cl) 2 ) 4 ], water vapor and nitrogen (N 2 ) flow rate is 20sccm, the thickness of the inorganic barrier layer is 19nm;

[0075] b) Preparation of the ...

Embodiment 3

[0079] A method for preparing an organic electroluminescent device, comprising the steps of:

[0080] (1), (2), (3) are the same as embodiment 1;

[0081] (4) Preparation of encapsulation layer:

[0082] a) Preparation of inorganic barrier layer: The inorganic barrier layer was prepared on the surface of the cathode by atomic layer deposition (ALD), the working pressure was 40Pa, the deposition temperature was 55°C; the material was chlorine-doped hafnium oxide (HfO 2 :Cl), the precursor used in the deposition of the inorganic barrier layer is tetrakis(dichloromethylamino)hafnium [Hf(N(CH 2 Cl) 2 ) 4 ] and water vapor, tetrakis(dichloromethylamino) hafnium [Hf(N(CH 2 Cl) 2 ) 4 ] injection time is 0.2s, water vapor injection time is 20ms, and nitrogen gas (N 2 ), tetrakis(dichloromethylamino) hafnium [Hf(N(CH 2 Cl) 2 ) 4 ], water vapor and nitrogen (N 2 ) flow rate is 10sccm, the thickness of the inorganic barrier layer is 15nm;

[0083] b) Preparation of organic ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com