Oil soluble thickening agent, production method and application in producing pesticide missible oil thereof

A thickener and oil-soluble technology, which is applied in the field of preparation of pesticide emulsifiable concentrates, can solve problems such as impossibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

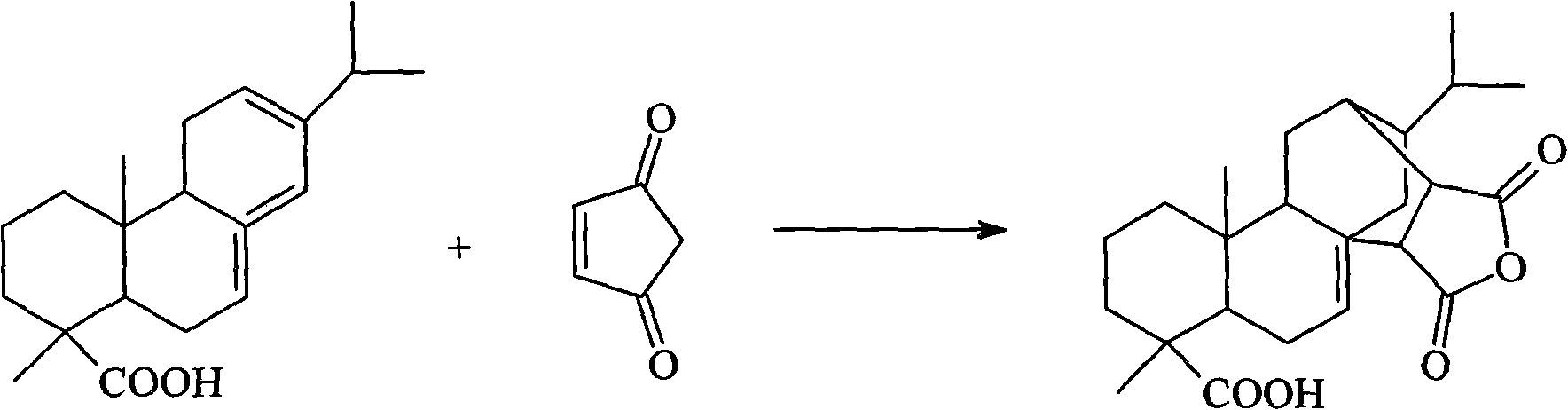

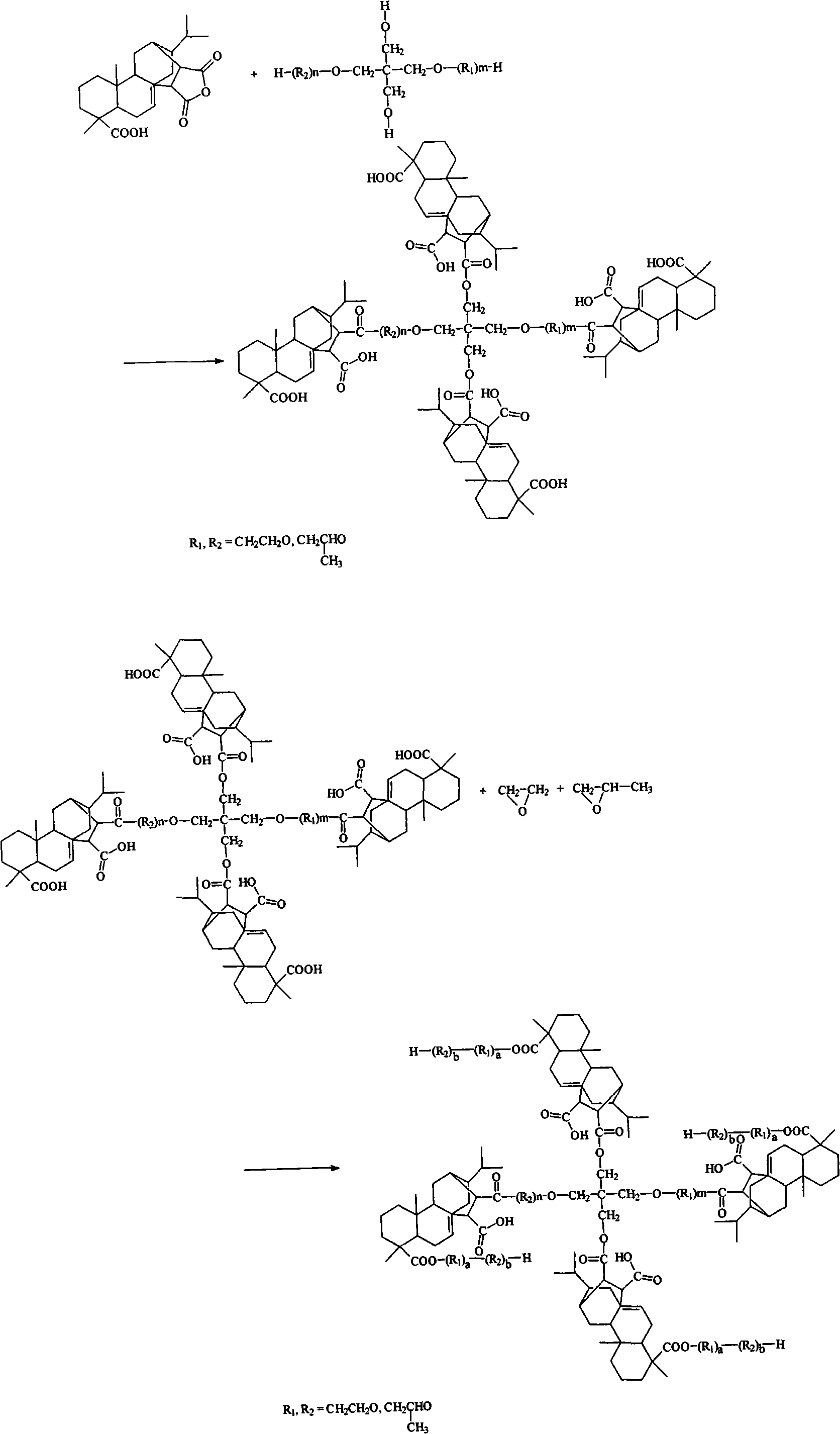

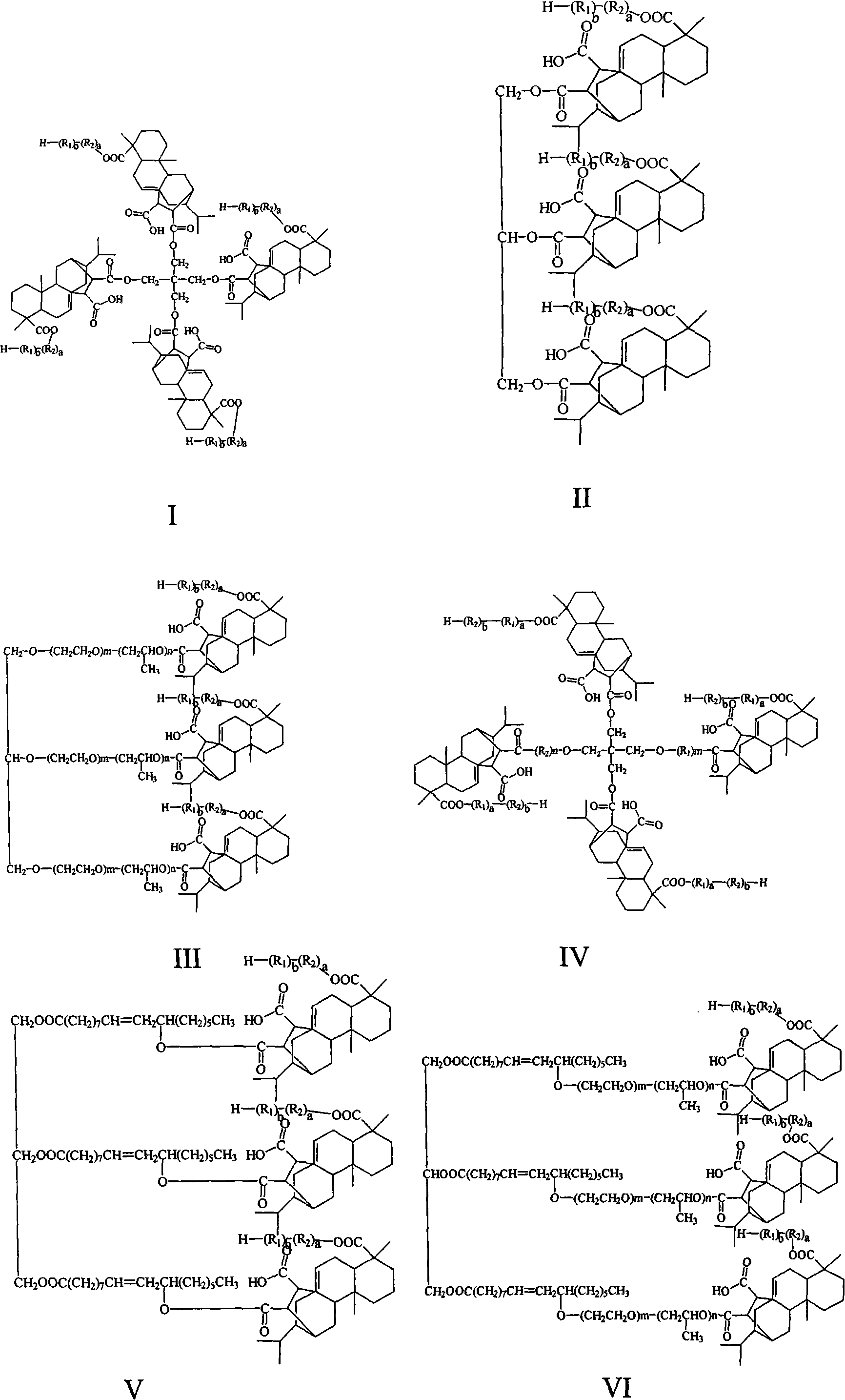

[0028] 400 g of rosin, 480 g of maleic anhydride, and 100 g of xylene were put into a 1L reactor, and after replacing the reactor with nitrogen, the temperature was controlled at 190-200° C., and the reaction was carried out for 1.5 hours to obtain the rosin derivative used in the present invention.

[0029] Put 100g of pentaerythritol and 1.2g of catalyst KOH into a 1L reaction kettle, replace the reaction kettle with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and then vacuum strip the gas for 2 hours, then introduce 100g of PO (propylene oxide) to control the reaction The temperature is 100-150°C, the pressure is 0.1-0.6MPa, after the PO is fed, the reaction is aged for 1.5hr, and then 120g of EO (ethylene oxide) is introduced at 120-170°C and the pressure is 0.1-0.6MPa. After finishing EO, react and age for 1.5hr, neutralize, absorb, dehydrate, degas, and filter with a leaf filter to obtain the pentaerythritol polyoxypropylene polyoxyethylene ether us...

Embodiment 2

[0033] 400 g of rosin, 480 g of maleic anhydride, and 100 g of toluene were put into a 1 L reactor. After the reactor was replaced with nitrogen, the temperature was controlled at 190-200° C. and the reaction was carried out for 1.5 hours to obtain the rosin derivative used in the present invention.

[0034] Put 100g of glycerol and 1.5g of catalyst KOH into a 1L reaction kettle, replace the reaction kettle with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and vacuum strip the gas for 2 hours, and then introduce 100g of EO (ethylene oxide) , control the reaction temperature at 120-170°C, and the pressure at 0.1-0.6MPa. After PO is fed, the reaction is aged for 1.5hr, and then 120 grams of PO (propylene oxide) is introduced at 100-150°C and 0.1-0.6MPa pressure. , After entering EO, react and age for 1.5hr, through neutralization, adsorption, dehydration, degassing, and filter with a blade filter to obtain glycerol polyoxyethylene polyoxypropylene ether used...

Embodiment 3

[0037] Put 400g of rosin, 480g of maleic anhydride, and 100g of dimethylformamide in a 1L reactor. After replacing the reactor with nitrogen, control the temperature at 190-200°C and react for 1.5 hours to obtain the rosin derivative used in the present invention. .

[0038] Put 100g of dimethylformamide, 60g of pentaerythritol, 40g of castor oil, and 660g of rosin derivatives into a 1L reactor, heat to dissolve the materials completely, then add 10g of catalyst p-toluenesulfonic acid, heat up from 140 to 160°C, and fully react for 5 After the reaction, carry out neutralization and dehydration, add catalyst KOH 2.4g, replace the reactor with nitrogen, vacuumize and dehydrate, raise the temperature to 110°C, and vacuum strip gas for 2 hours, then feed PO (propylene oxide) 168g, control The reaction temperature is 120-170°C, the pressure is 0.1-0.6MPa, after the PO is fed, the reaction is aged for 1.5hr, and then 176g of EO (ethylene oxide) is fed under the conditions of 120-170...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com