CAST segmenting water feed reinforced denitrification process control system

A process control system, a technology of staged water inflow, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Nitrogen removal efficiency and other problems, to achieve the effect of low cost, convenient management and operation, and solve the improvement of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

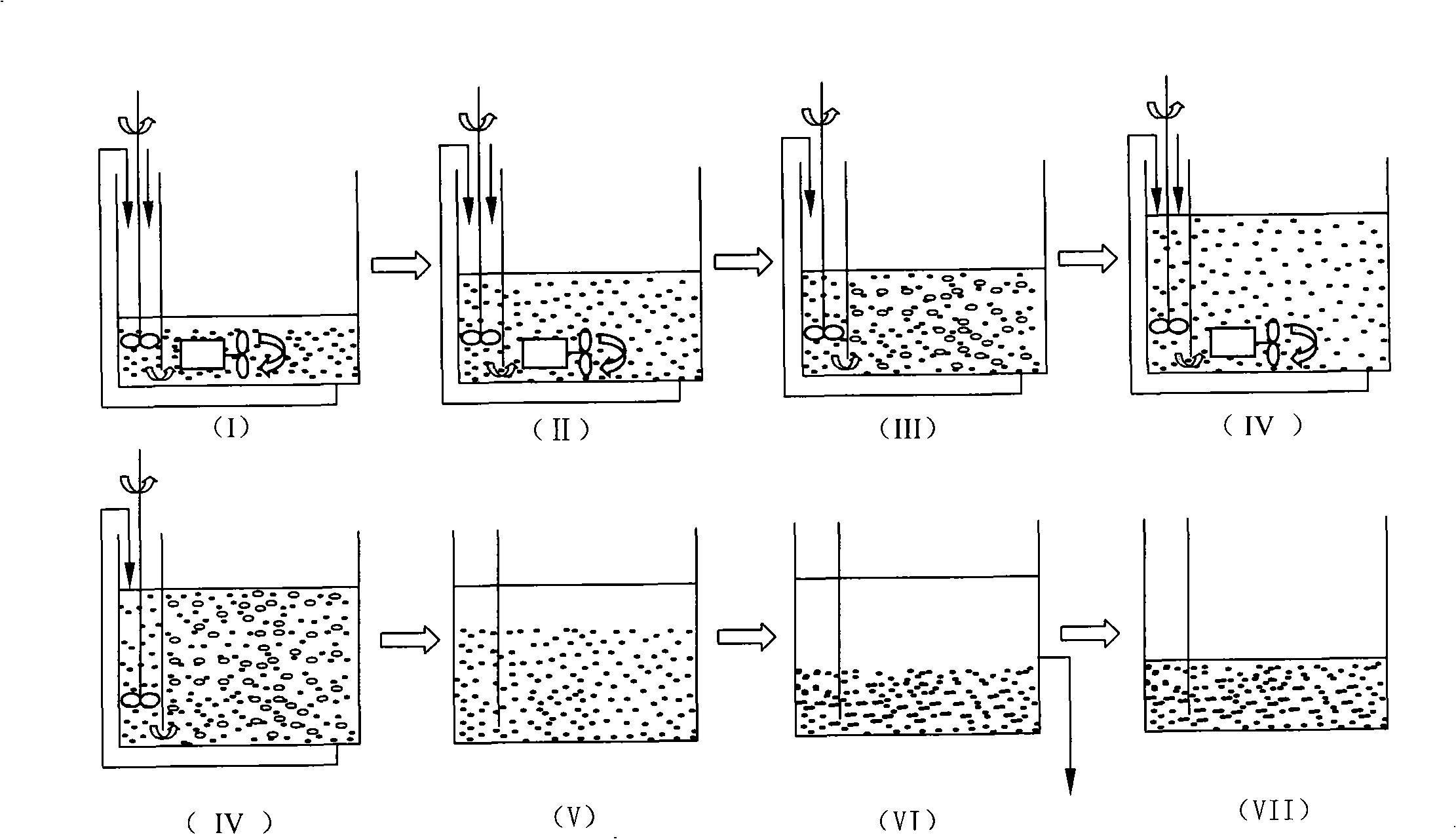

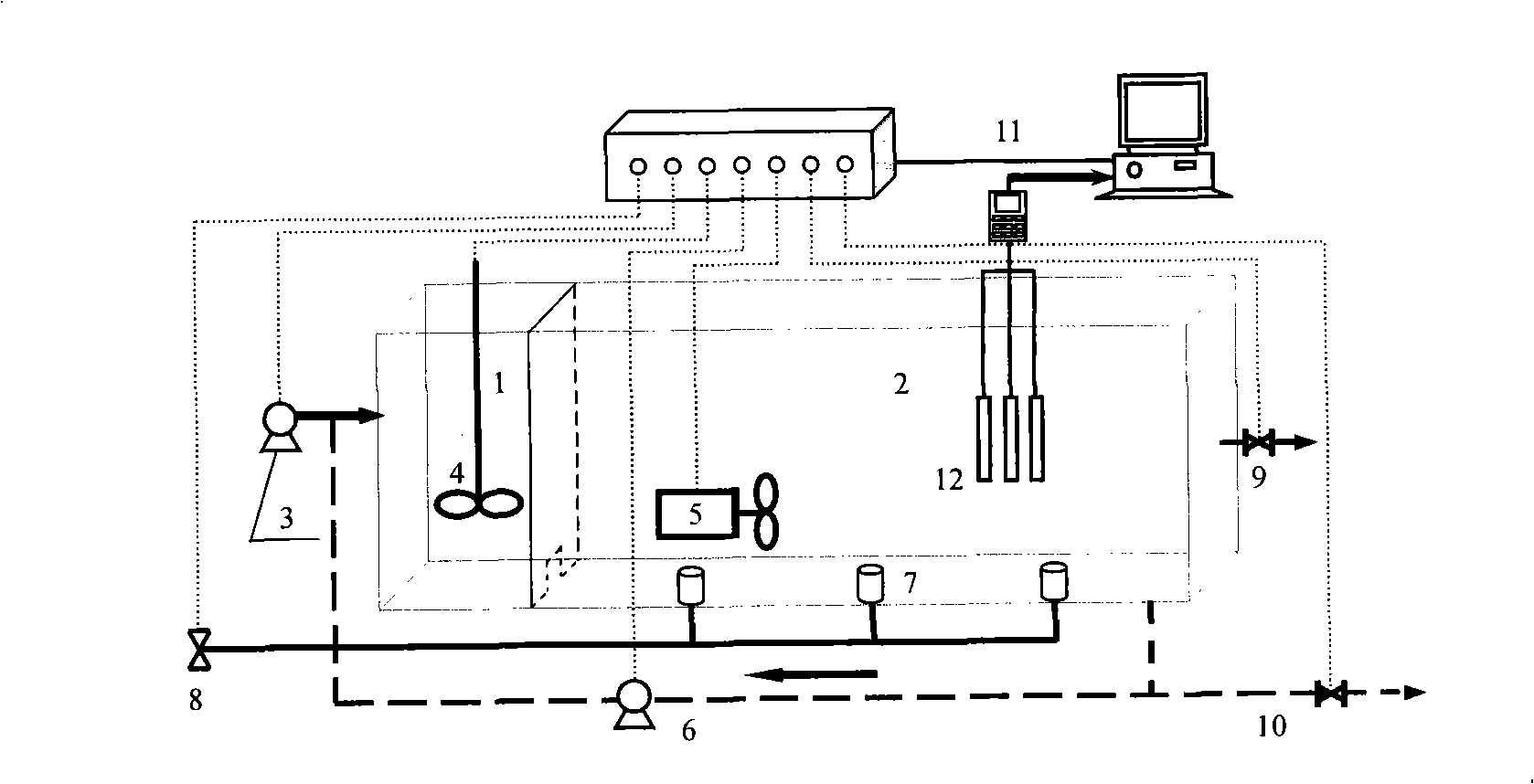

Method used

Image

Examples

Embodiment

[0045] The actual domestic sewage discharged from a family area of a university was used as the experimental object (pH=6.5~7.8, COD=260~350mg / L, TN=60~85mg / L, TP=3.5~6.8mg / L). The selected CAST reactor has an effective volume of 18L, the initial MLSS in the reactor is 3.5-4.0g / L, and the aeration rate is constant at 0.25m 3 / h, the mud age is maintained at about 10d, and the reaction temperature is 23°C. Using the CAST segmented water inlet to strengthen the denitrification process control system, the treated water volume is 6L, the number of segments is 3 times, the COD removal rate is over 85%, the total nitrogen removal rate is over 90%, the total phosphorus removal rate is over 90%, and the final effluent COD is less than 50mg / L, total nitrogen is less than 10mg / L, which is lower than the total nitrogen concentration required by the national first-level emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com