Method for extracting and separating levorotation-synephrine from green tangerine orange peel

A technology of green bark and extract, which is applied in chemical instruments and methods, medical preparations containing active ingredients, pharmaceutical formulas, etc., and can solve problems such as unrealized separation and identification of synephrinesynephrine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

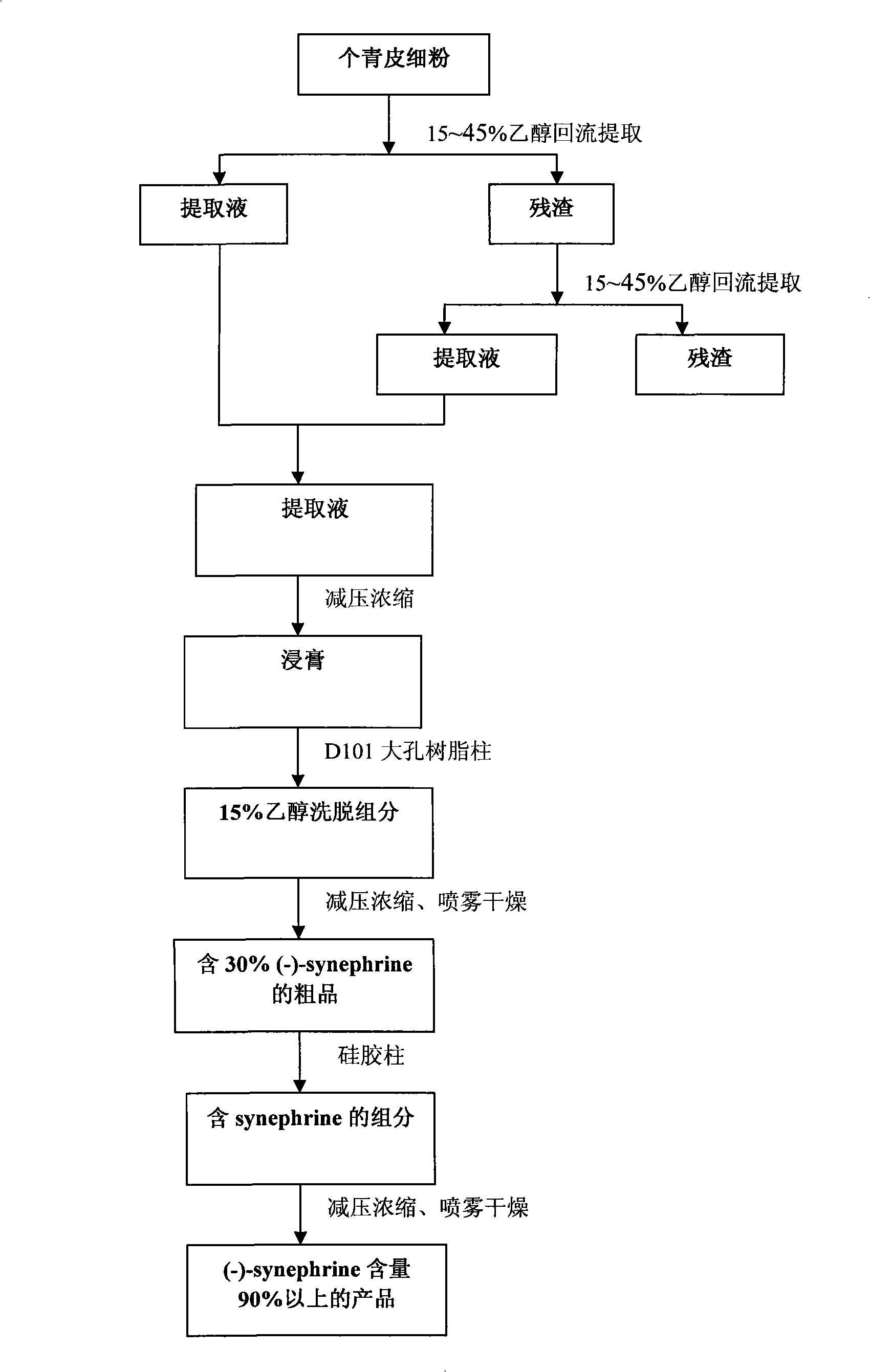

Method used

Image

Examples

Embodiment 1

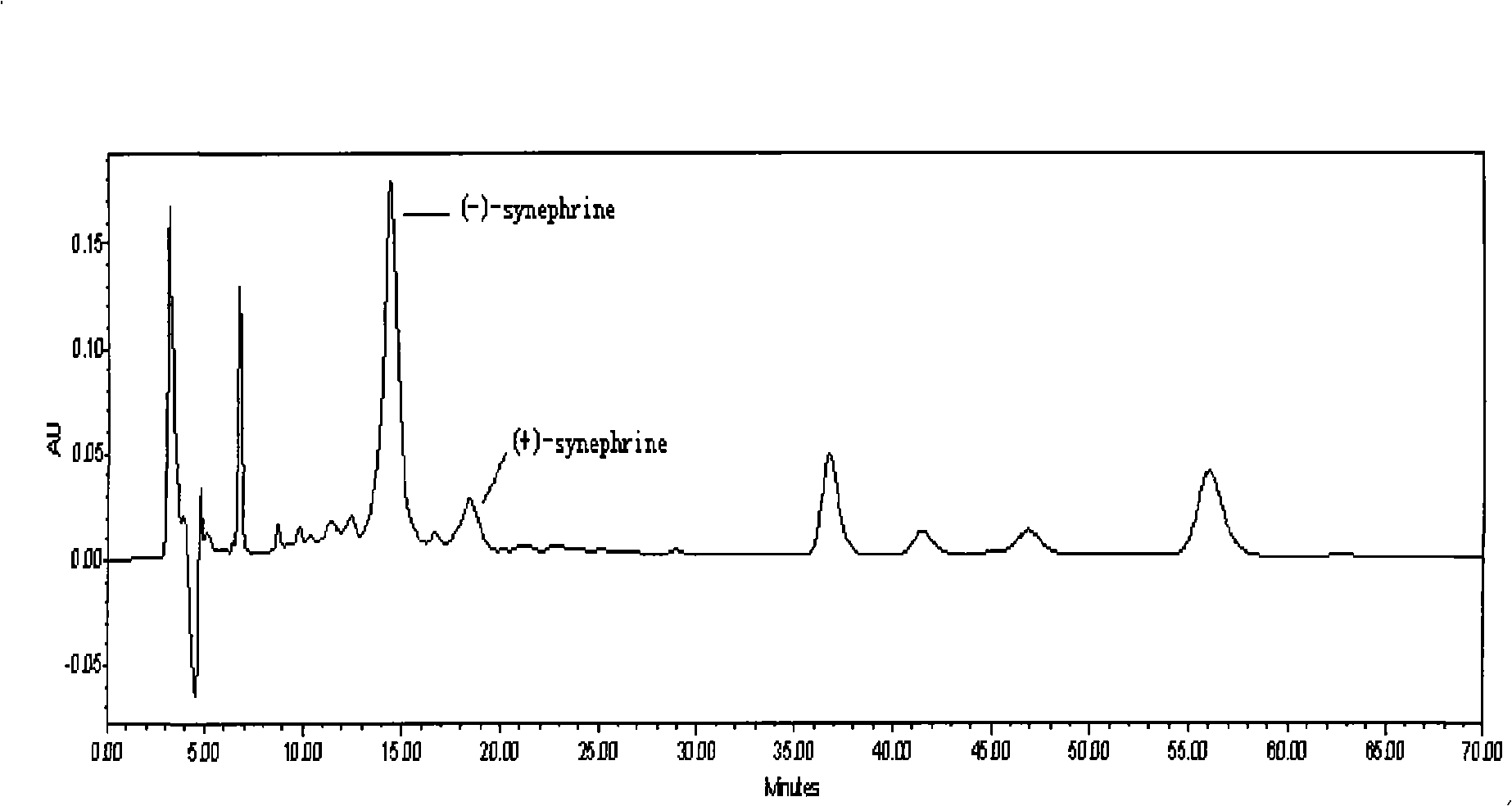

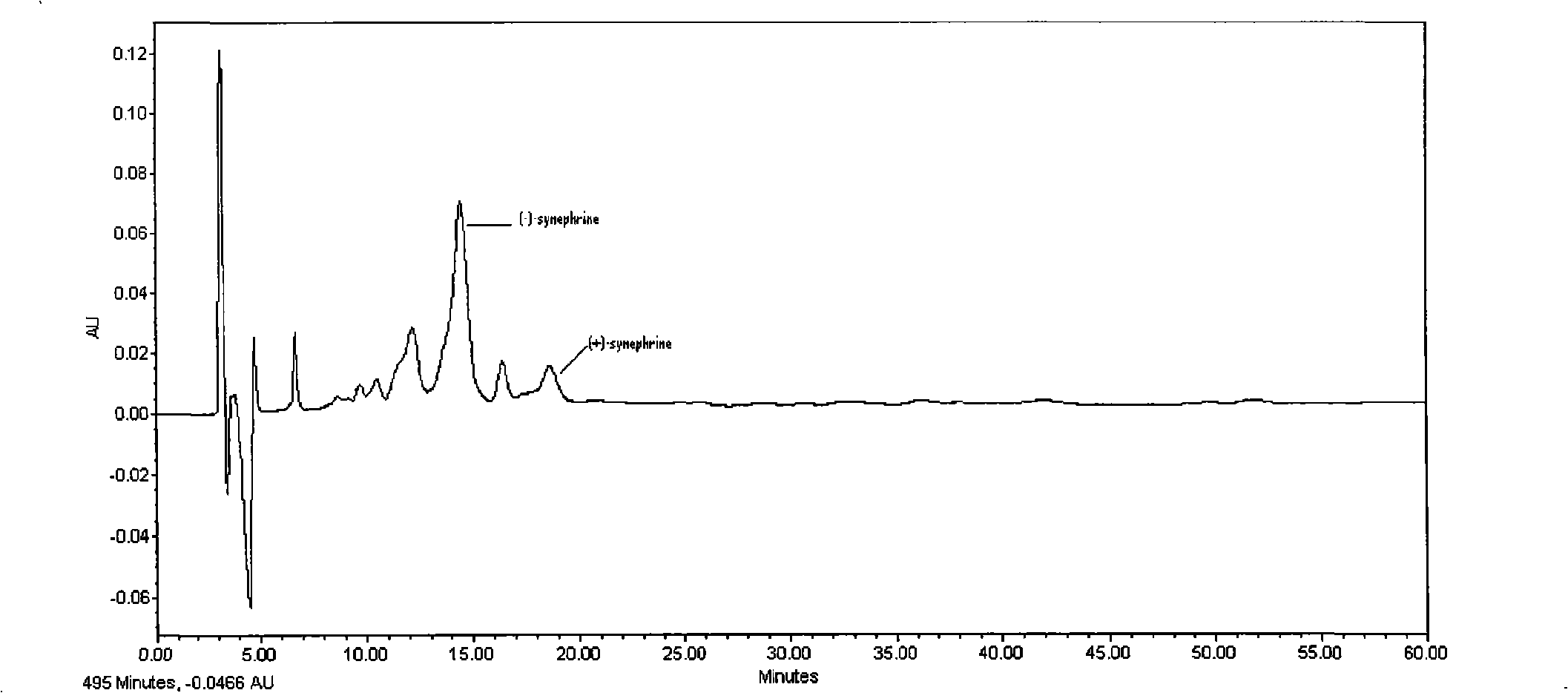

[0020] Chop green peel, grind into powder, and freeze-dry to get green peel fine powder. Weigh 100g of Qingpi fine powder, add 2L of 15% ethanol solution, extract twice in the extraction reflux device under the condition of 80°C, concentrate the extract under reduced pressure to obtain 14g of extract, add 50mL of water to dissolve the extract, and make the solid content 80-85%, put the sample on a 500mL D101 macroporous resin column, wash it with 2 times the volume of distilled water, and then elute with 4 times the volume of 15% ethanol solution, using a vacuum of 0.06-0.09Mpa and a temperature of 40- The eluate was concentrated under reduced pressure at 50°C, and then spray-dried at a temperature of 50-60°C to obtain 2.8 g of the crude product, which was determined by high-performance liquid chromatography using a ChiralPakAD-H chiral column, wherein the content of (-)-synephrine was 30.3%. Dissolve the crude product in pure ethanol, stir in silica gel of the same quality a...

Embodiment 2

[0022] Weigh 4.5kg of Qingpi fine powder, add 70L of 30% ethanol solution, extract twice in the extraction reflux device at 80°C, concentrate the extract under reduced pressure to obtain 500mL of extract, add 1.5L of water to dissolve the extract, and load it on The 5L D101 macroporous resin column was first washed with 2 times the volume of distilled water, and then eluted with 4 times the volume of 15% ethanol solution. After the eluent was concentrated under reduced pressure, it was spray-dried to obtain 102 g of crude product, wherein the (-)-synephrine content was about was 31.1%. The crude product was dissolved in ethanol, mixed with silica gel of the same quality as the crude product, and the ethanol was evaporated to obtain a silica gel adsorption sample. The silica gel adsorption sample was loaded on a 3L silica gel column, eluted with the eluent prepared by dichloromethane:methanol:ammonia water=8:2:0.1, and the eluted fraction containing synephrine was collected, co...

Embodiment 3

[0024] Weigh 20kg of Qingpi fine powder, add 300L 40% ethanol solution, extract twice in the extraction reflux device at 80°C, concentrate the extract under reduced pressure to obtain 2L of extract, add 3L of water to dissolve the extract, and load it on a 20L container D101 macroporous resin column, rinsed with 2 times volume of distilled water first, then eluted with 4 times volume of 15% ethanol solution, and the eluent was concentrated under reduced pressure and spray-dried to obtain 432g of crude product, wherein the content of (-)-synephrine was about 30.9 %. The crude product was dissolved in ethanol, mixed with silica gel of the same quality as the crude product, and the ethanol was evaporated to obtain a silica gel adsorption sample. Load the silica gel adsorption sample on a 30L silica gel column soaked in dichloromethane, elute and collect with the eluent prepared by dichloromethane: methanol: ammonia water = 9:2:0.1, collect the components containing synephrine, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com