Current mirror type TFT-OLED display image element unit circuit and its production method

A technology of TFT-OLED and display pixels, which is applied in the field of thin-film microelectronic circuit design and device preparation, can solve problems such as uneven display brightness of the display screen, and achieve the effect of improving image response speed, consistency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

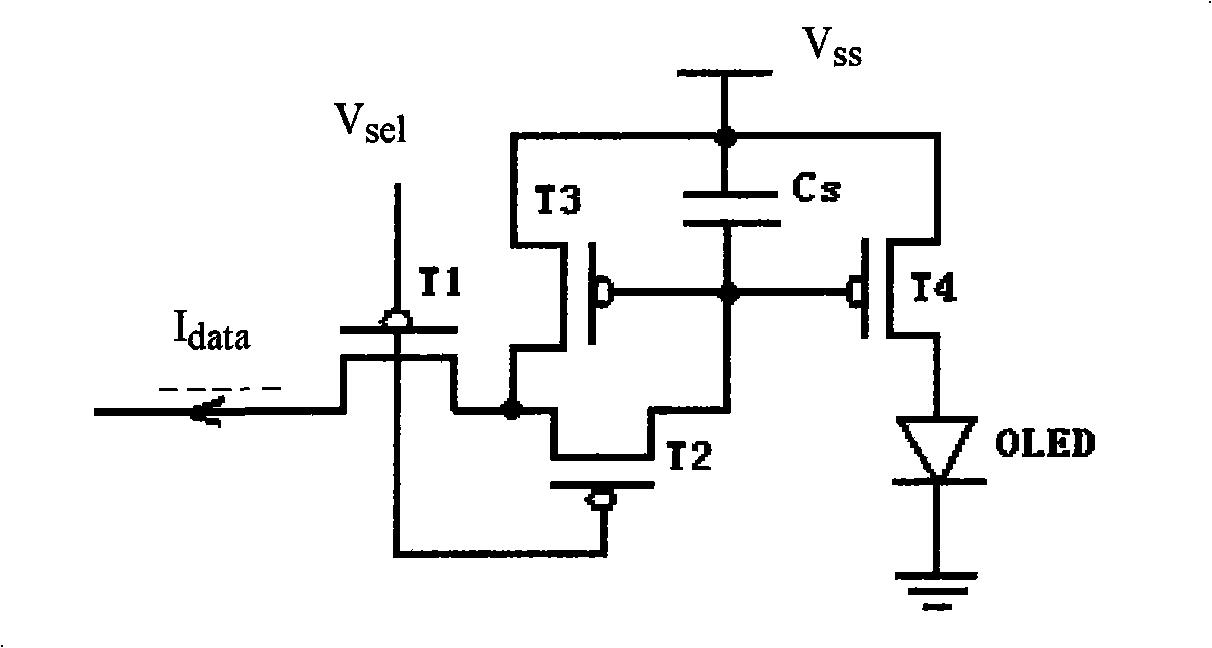

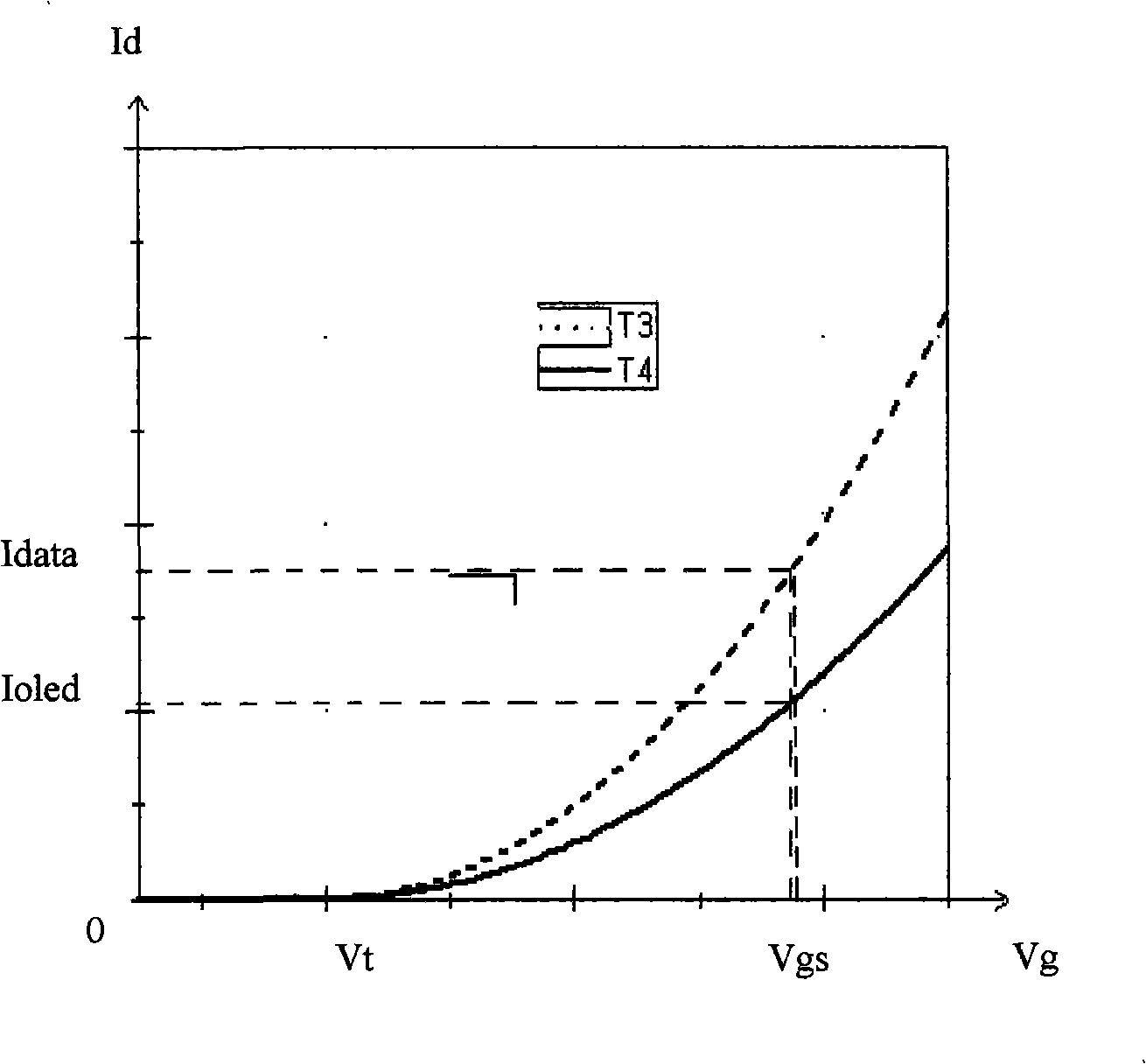

[0071] The invention provides a method for preparing a high-performance polysilicon thin film transistor current mirror by adopting a method of metal-induced single-direction lateral crystallization or laser crystallization. Use amorphous silicon metal to induce single-direction lateral crystallization or laser crystallization to form polysilicon islands on the dehydrogenated amorphous silicon film, and select the crystallization intervals in the polysilicon islands in parallel as the channels of mirror transistors T3 and T4 respectively Area, forming a specific high-quality polysilicon TFT tube layout. Compared with the conventional current mirror, the device carrier mobility, threshold voltage, gate capacitance and sub-threshold swing of the two mirror tubes prepared by the present invention are very close, and the ratio of the mirror current depends on the ratio of the two TFTs more accurately. The ratio of width to length.

[0072] In the present invention, the conduction...

specific Embodiment approach 1

[0100] The invention provides a method for preparing lateral crystallization of a thin film field effect transistor TFT in a current mirror type TFT-OLED display pixel unit circuit. The method adopts a metal-induced single-direction lateral crystallization technology.

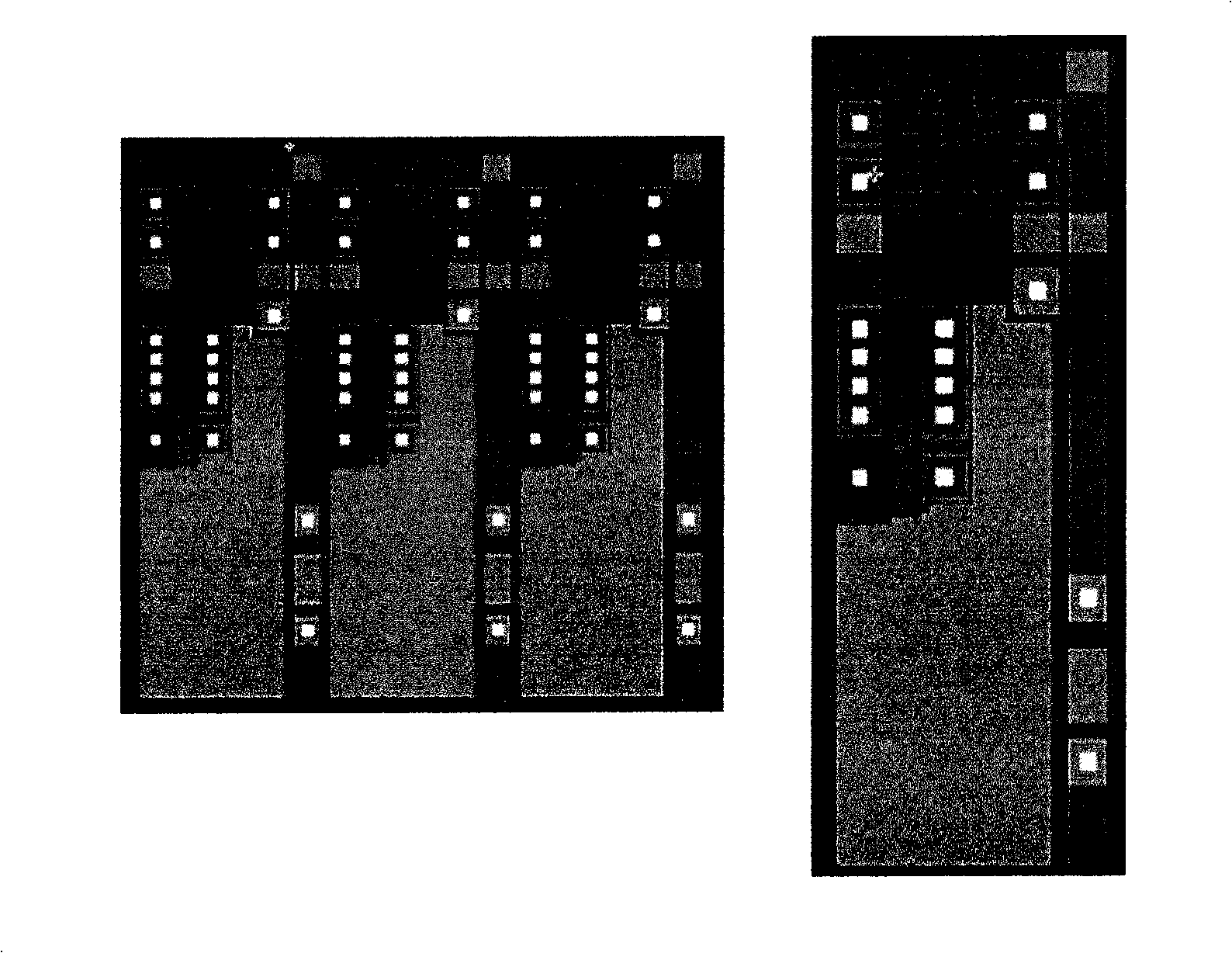

[0101] Such as image 3 As shown, the present invention is on a transparent glass substrate, on a polysilicon island prepared by metal-induced unidirectional lateral crystallization, according to the method for constructing a current mirror with the above-mentioned thin film transistor, the method ensures that the device has the same characteristics as conventional MIUC polysilicon TFT On the basis of the excellent performance of the current mirror, the specific position of the two mirror tubes is set by using a specific current mirror layout design, which obviously improves the mirror image characteristics of the current mirror.

[0102] Such as Figure 4 , Figure 5 As shown, the substrate material for prep...

specific Embodiment approach 2

[0110] The invention also provides a laser crystallization preparation method of a thin film field effect transistor TFT in a current mirror type TFT-OLED display pixel unit circuit, and the method adopts a laser crystallization technology.

[0111] The present invention is a method for constructing a current mirror by preparing a laser crystallized thin film transistor on a polysilicon island on a transparent glass substrate. The mirror layout design sets the specific positions of the two mirror tubes in the laser crystallization process, which significantly improves the mirror image characteristics of the current mirror.

[0112] Such as Figure 18 As shown, the substrate material for preparing polysilicon devices is transparent substrate glass 201. In order to block impurities in the glass substrate, they diffuse into the active layer during the thermal process of device preparation, and deposit silicon nitride on the glass substrate and LTO hybrid layer 202 . The precurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com