Non-gap bonding course GaN based illuminating device and its production method

A light-emitting device, seamless technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor bonding between GaN-based light-emitting devices and supporting components, reduce the incidence of cracks, help heat dissipation, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

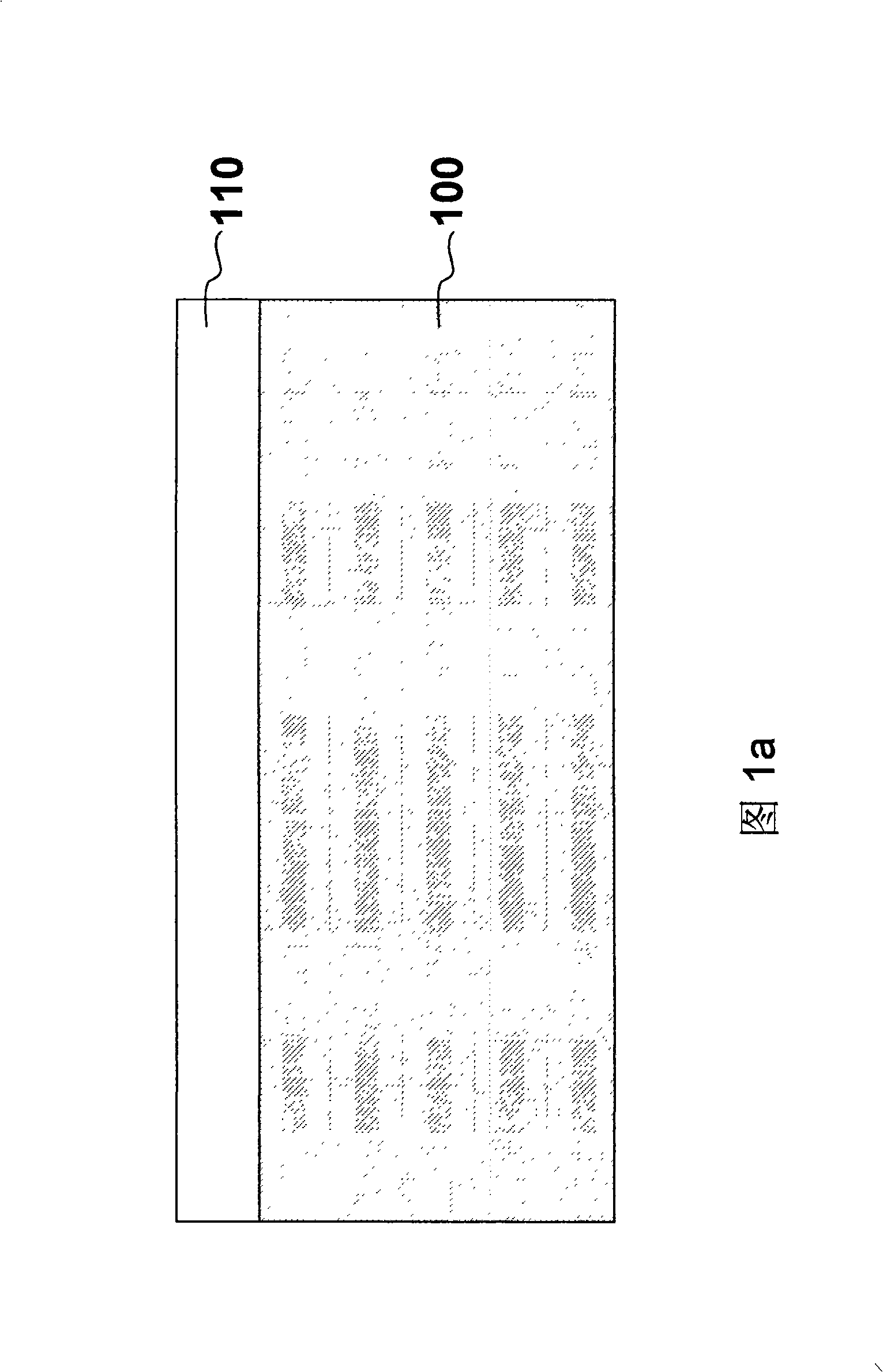

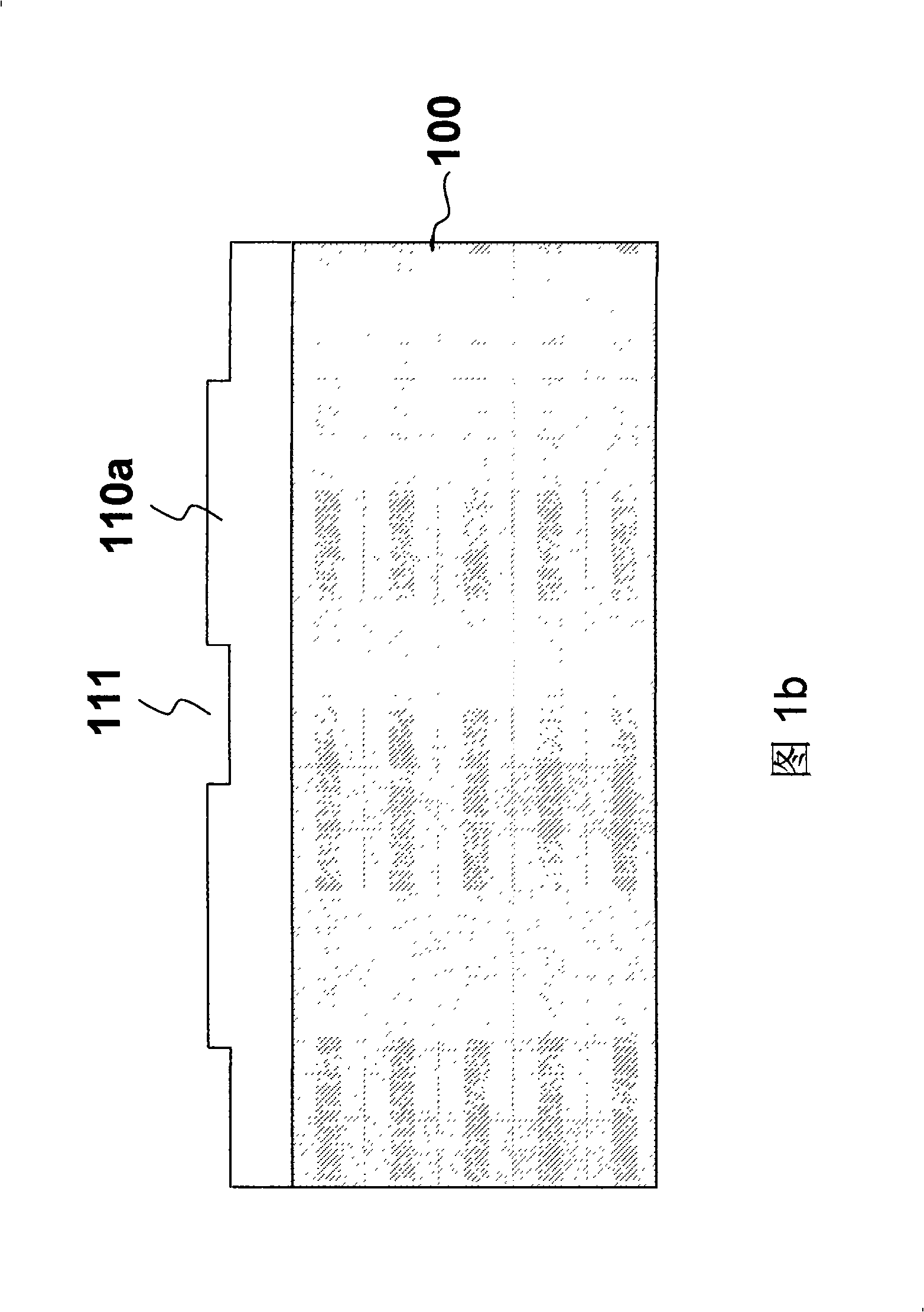

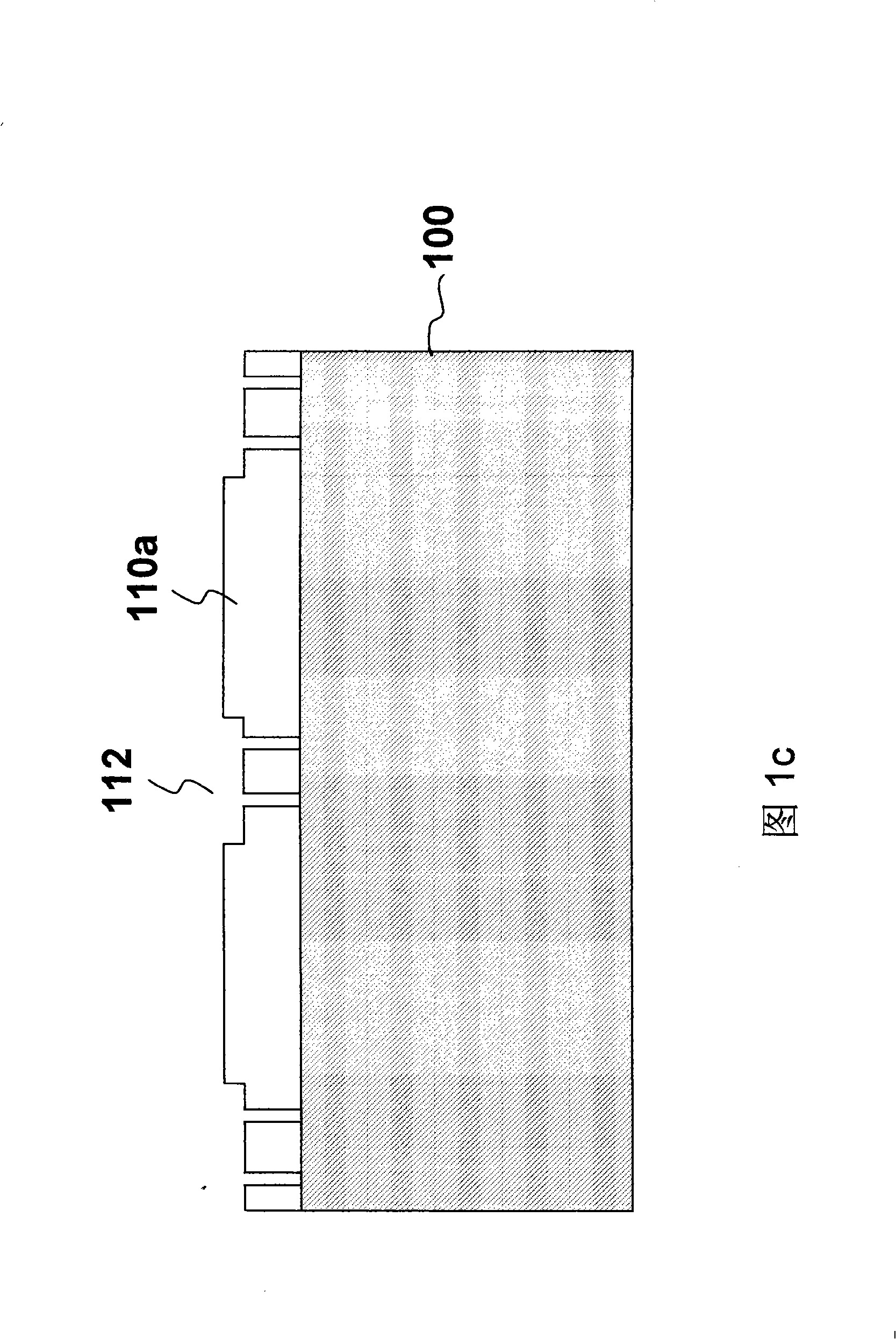

[0023] A GaN-based light-emitting device with a seamless bonding process as shown in Figure 2, including a GaN-based epitaxial film 110 with an N semiconductor layer, an active layer and a P semiconductor layer; an ohmic contact and a metal reflective layer are formed under the P semiconductor layer 120, the reflective metal film material is preferably Ag, with a thickness of 50-500nm; a multilayer metal film 150 is formed under the reflective metal film; a eutectic solder layer 160 is formed on the multilayer metal film 150; the eutectic solder layer 160 is connected with the support The component 200 is bonded; the N electrode 170 material layer is formed on the N semiconductor layer; the P electrode 210 material layer is formed at the bottom of the supporting component; the side wall of the GaN-based light-emitting device of the present invention wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com