Splicing PCB board produced by paper fiber sheet material

A technology for making PCB boards and plates, which is applied in the direction of assembling printed circuits and printed circuit components with electrical components, which can solve problems such as breaking, failure, and fiber length, and achieve the effect of avoiding cracks and reducing the effect of thermal expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

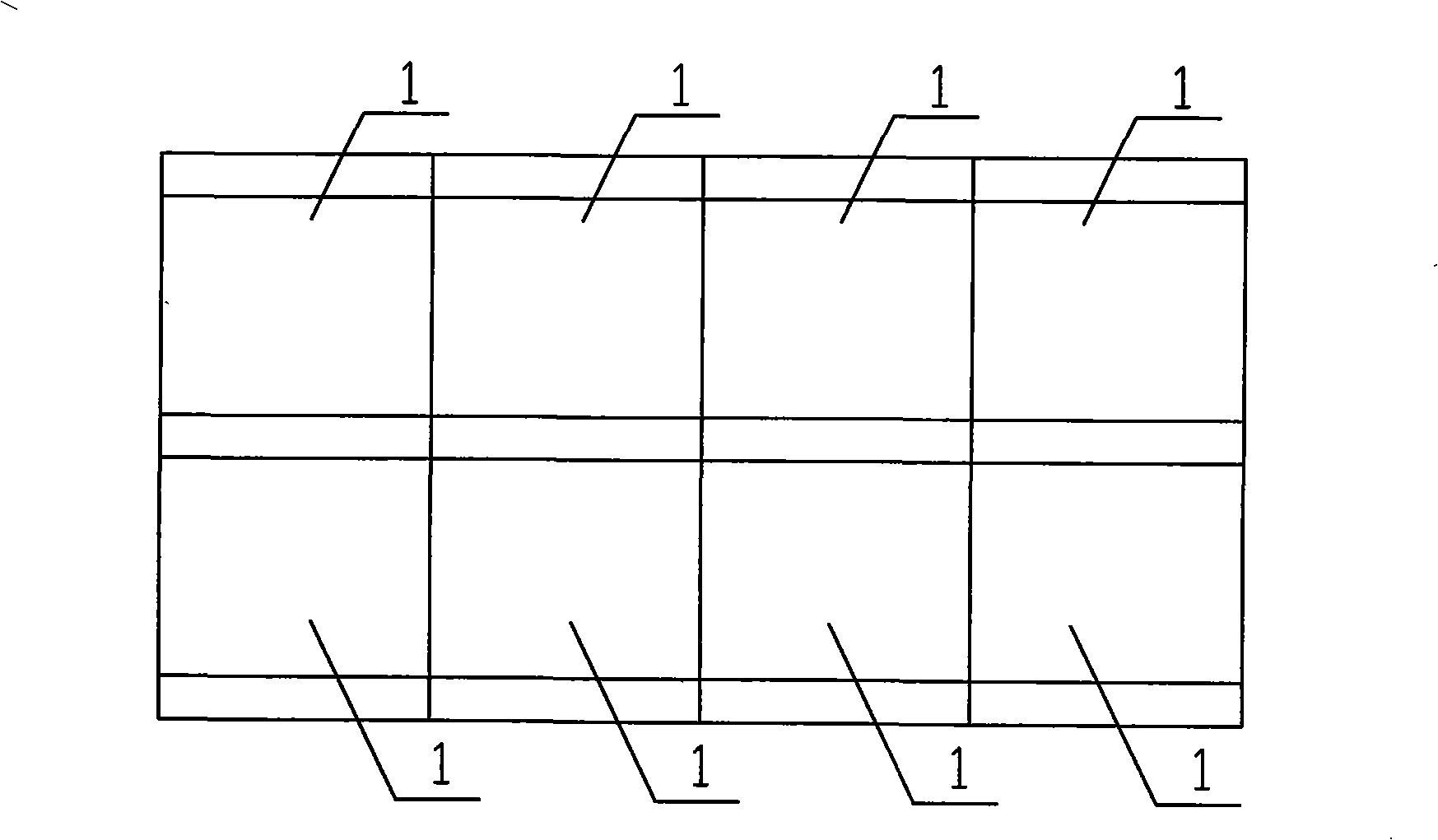

[0015] Implementation method: figure 1 Shown is a schematic structural diagram of a spliced PCB board made of paper fiber boards in the prior art. It is mainly composed of multiple PCB units 1 spliced into a whole PCB board. Each PCB unit 1 is assembled with zero spacing, and " V" shaped pit. If the spliced PCB board with this structure has a large area, the spliced PCB board will undergo physical changes in thermal expansion and contraction during the high-temperature reflow soldering process, which will cause cracks in the spliced PCB board and cause the product to be scrapped.

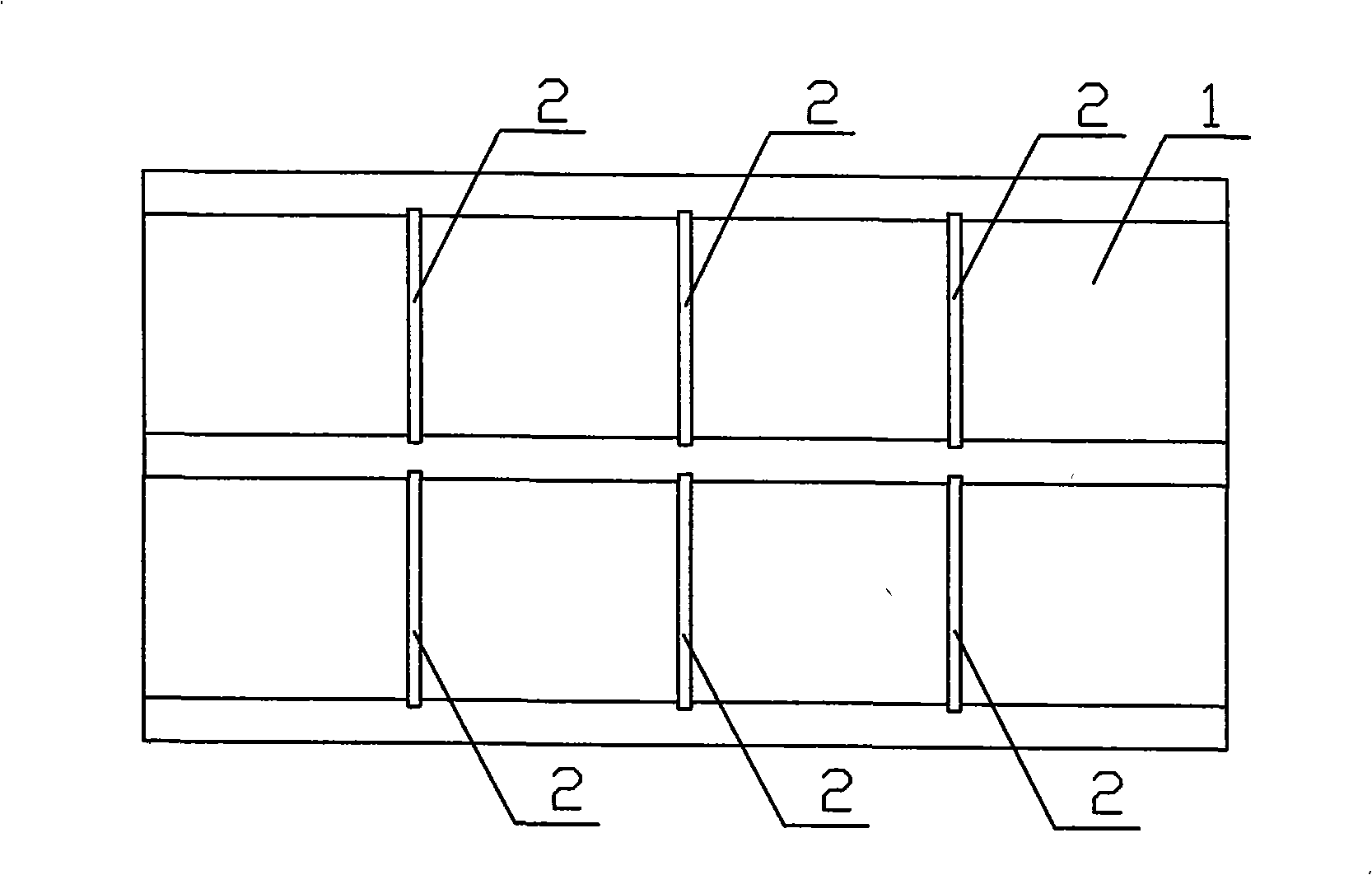

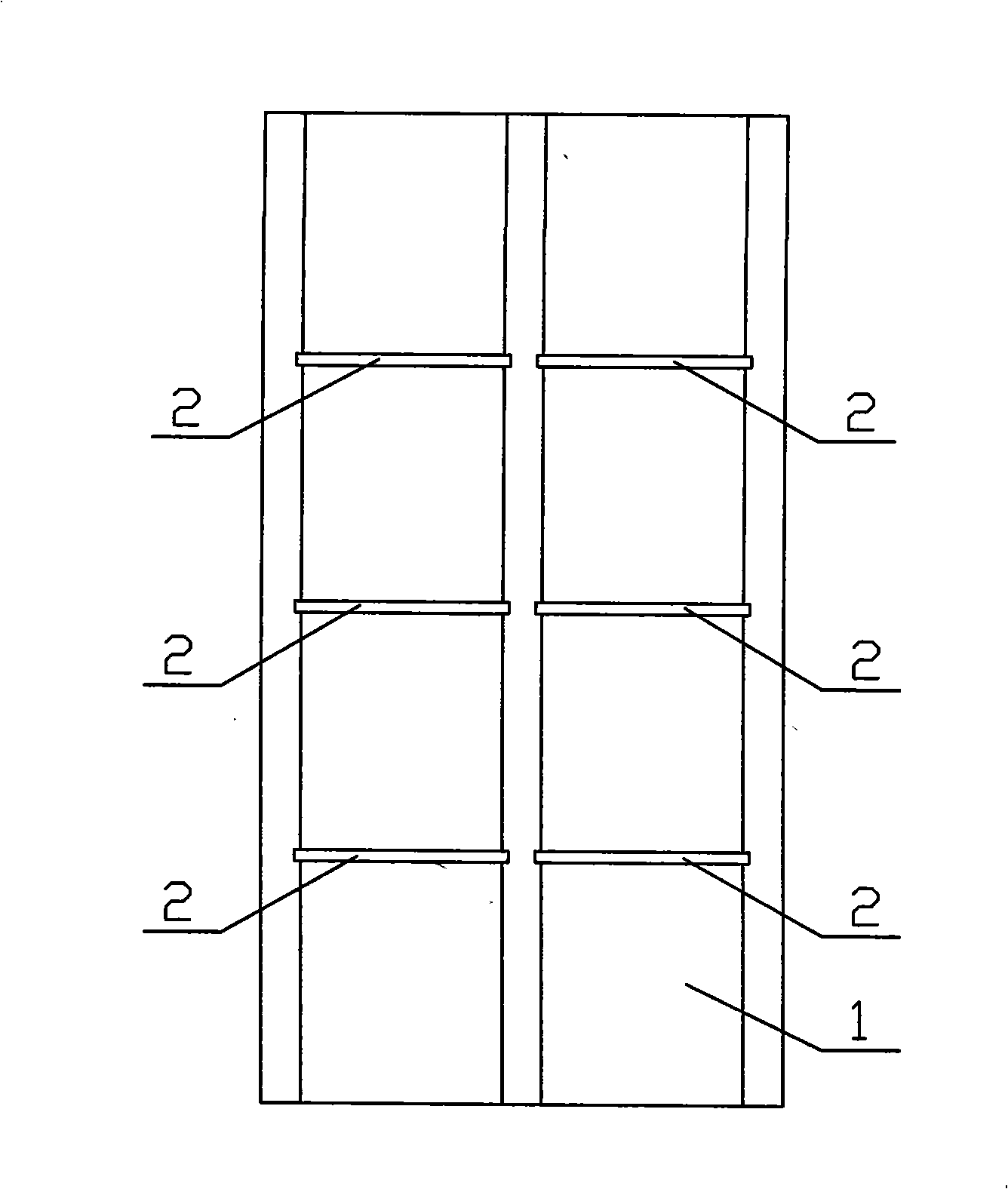

[0016] In order to overcome this problem, the present invention improves the structure of the spliced PCB board made of paper fiber board. like figure 2 As shown, a plurality of PCB units 1 are spliced into a whole PCB board, and there are two rows and three rows of six elongated slots 2 in the longitudinal direction on the spliced PCB board. The fiber length of the board is chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com