On-line control method of continuous casting blank temperature based on memory recognition mode

A technology for identifying modes and control methods, which is applied in the field of continuous casting of steel materials and other metal materials in the metallurgical process, can solve the problems of limited control effects, harsh temperature measurement environment, and many interference factors, so as to achieve easy application and make up for lag Sexuality and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

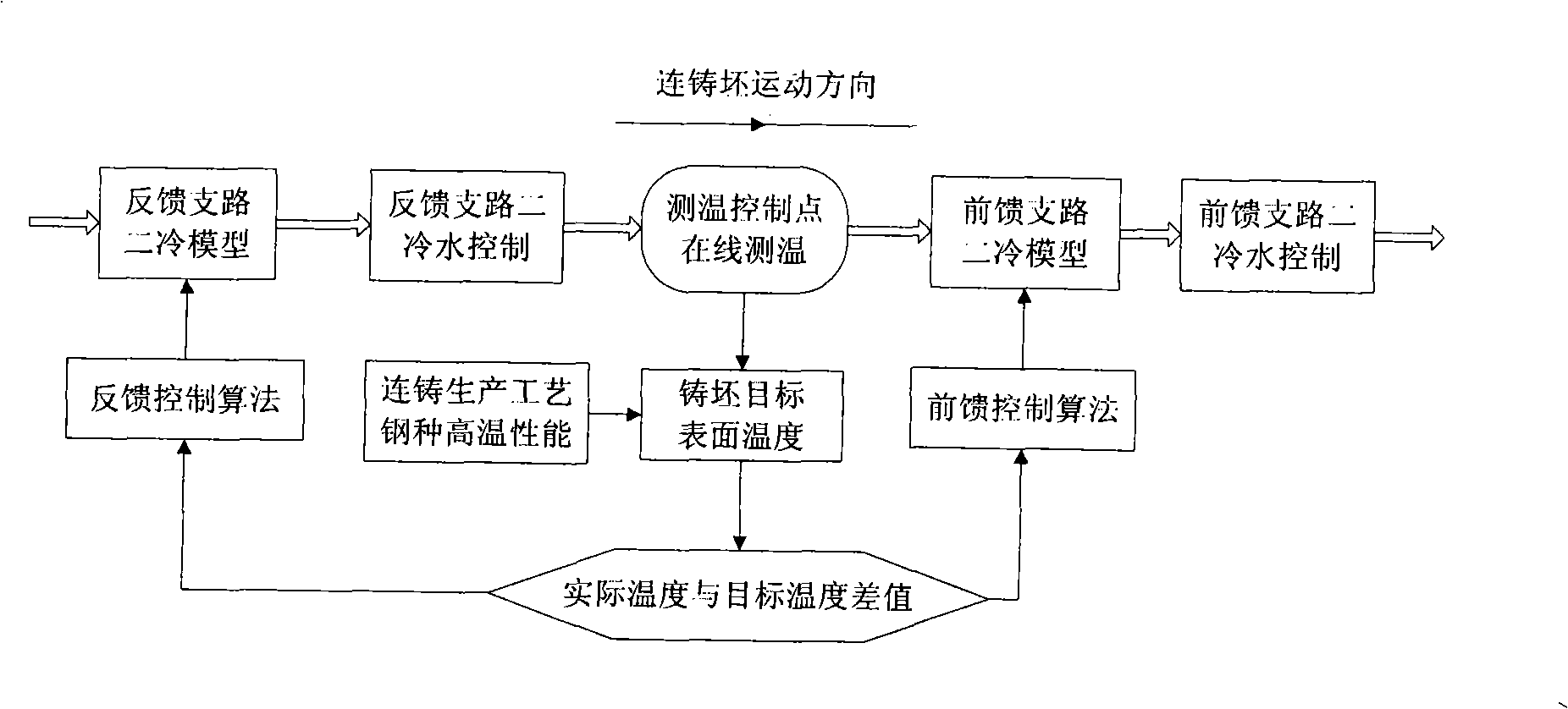

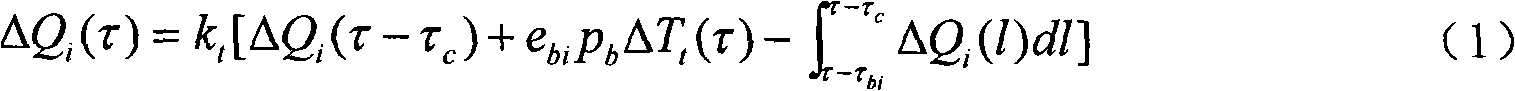

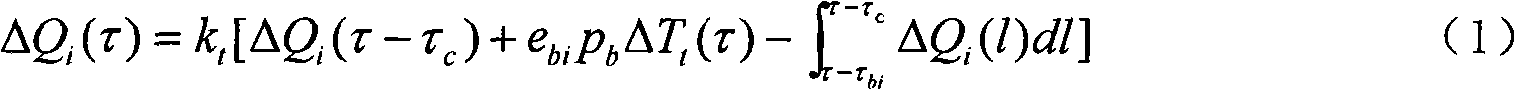

[0054] An on-line control method of continuous casting slab temperature based on memory recognition mode. According to the characteristics of continuous casting process, the computer control system applies the feedback and feedforward complementary control model algorithm based on memory recognition mode to control the water distribution of the entire secondary cooling zone of the continuous casting machine. The system performs real-time compensation control to keep the surface temperature of the slab at the set temperature measurement control point within the target temperature range, thereby ensuring the quality of the slab and continuous casting production; the specific steps include:

[0055] 1) On-line measurement of continuous casting slab temperature

[0056] The temperature measurement control point is set in the secondary cooling zone of the continuous casting machine, usually in the continuous casting slab straightening area; there is a secondary cooling circuit befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com