Method for extracting and separating curcuma oil

A separation method and technology of turmeric oil, which is applied in the fields of pharmaceutical formulations, fat oil/fat production, medical preparations containing active ingredients, etc., can solve problems that do not involve the separation of turmeric oil, etc., and achieve solvent residues, strong fragrance, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

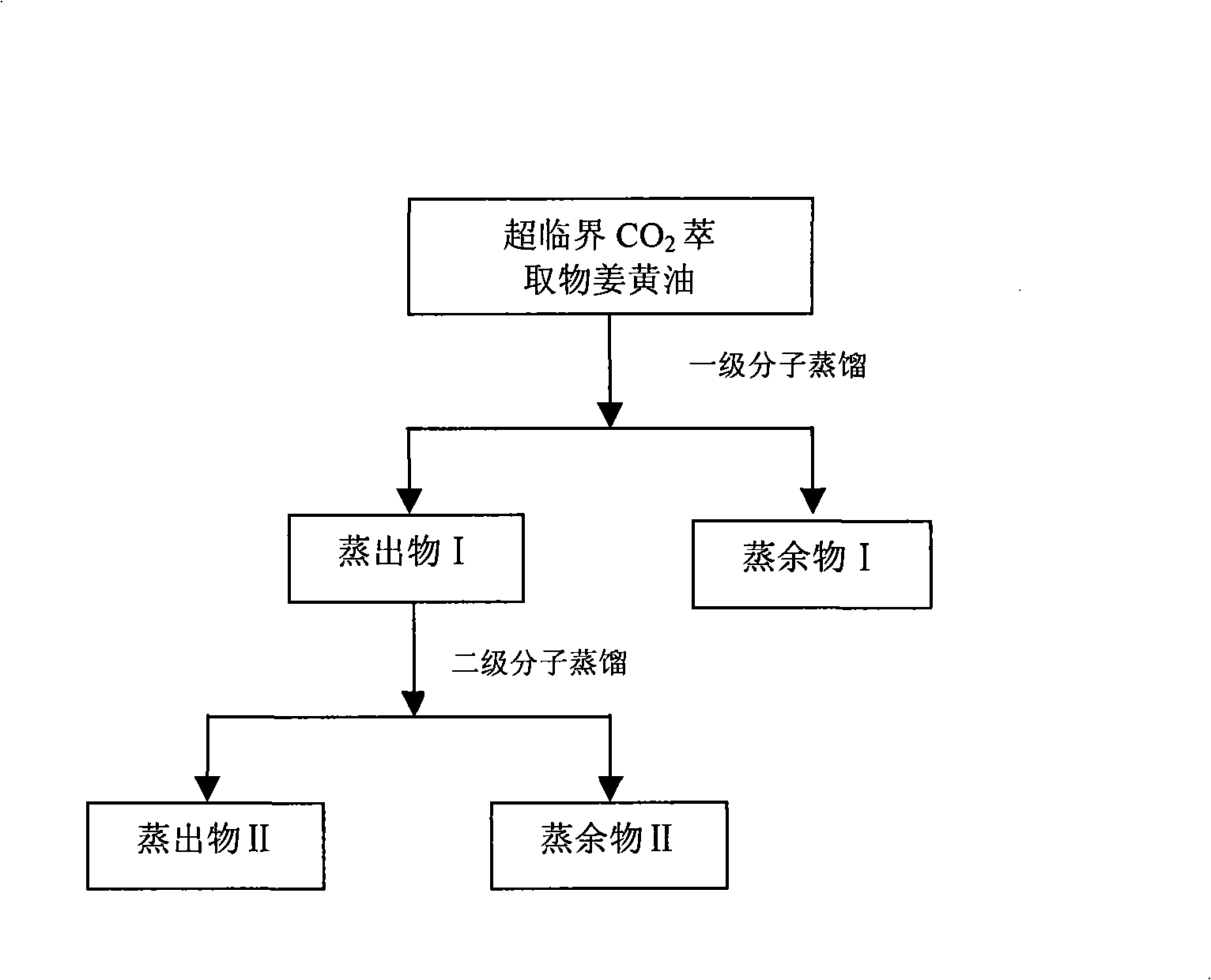

Method used

Image

Examples

Embodiment 1

[0019] Weigh 100g of turmeric powder, put it into the barrel, put it into the extraction kettle, raise the temperature and pressurize, and preset it statically at a pressure of 10Mpa and a temperature of 30°C for 15min, then extract the statically processed turmeric powder at an extraction pressure of 30Mpa and an extraction temperature of 45°C. CO 2 The flow rate is 40L / h, and the extraction time is 120min for dynamic circulation extraction. The yield of turmeric oil is 8.9%. Add 40mL of turmeric oil into the molecular still, carry out molecular distillation under the conditions of operating pressure 10Pa, distillation temperature 80°C, condensation temperature 2°C, feed rate 3mL / min, feed temperature 45°C, wiper speed 300r / min, The amount of distillate was 81.1%. The distillate from the primary molecular distillation is subjected to secondary molecular distillation. When the distillation pressure is 260Pa, the distillation temperature is 50°C and the rotation speed of the ...

Embodiment 2

[0021] Weigh 50g of turmeric powder, put it into the barrel, put it into the extraction kettle, heat up and pressurize, and preset it statically for 15 minutes at a pressure of 10Mpa and a temperature of 30°C, and then extract the statically processed turmeric powder at an extraction pressure of 30Mpa and an extraction temperature of 45°C. CO 2 The flow rate is 40L / h, and the extraction time is 120min for dynamic circulation extraction. The yield of turmeric oil is 8.8%. Supercritical CO 2 The extracted turmeric oil is added to a molecular distillation kettle, and the molecular distillation is carried out under the conditions of an operating pressure of 15 Pa, a distillation temperature of 85°C, a condensation temperature of 2°C, a feed rate of 3mL / min, a feed temperature of 45°C, and a wiper speed of 300r / min , Molecular distillation distillate is 78.0%. The distillate from the primary molecular distillation is subjected to secondary molecular distillation. When the distil...

Embodiment 3

[0023] Weigh 150g of turmeric powder, put it into the barrel, put it into the extraction kettle, heat up and pressurize, and preset it statically for 15 minutes at a pressure of 10Mpa and a temperature of 30°C, and then extract the statically processed turmeric powder at an extraction pressure of 30Mpa and an extraction temperature of 45°C. CO 2 The flow rate is 40L / h, and the extraction time is 120min for dynamic circulation extraction. The yield of turmeric oil is 8.9%. Supercritical CO 2 The extracted turmeric oil is added to the molecular distillation kettle, and the molecular distillation is carried out under the conditions of operating pressure 20Pa, distillation temperature 85°C, condensation temperature 2°C, feed rate 3mL / min, feed temperature 45°C, and wiper speed 300r / min , Molecular distillation distillate is 75.0%. The distillate from the primary molecular distillation is subjected to secondary molecular distillation. When the distillation pressure is 160Pa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com