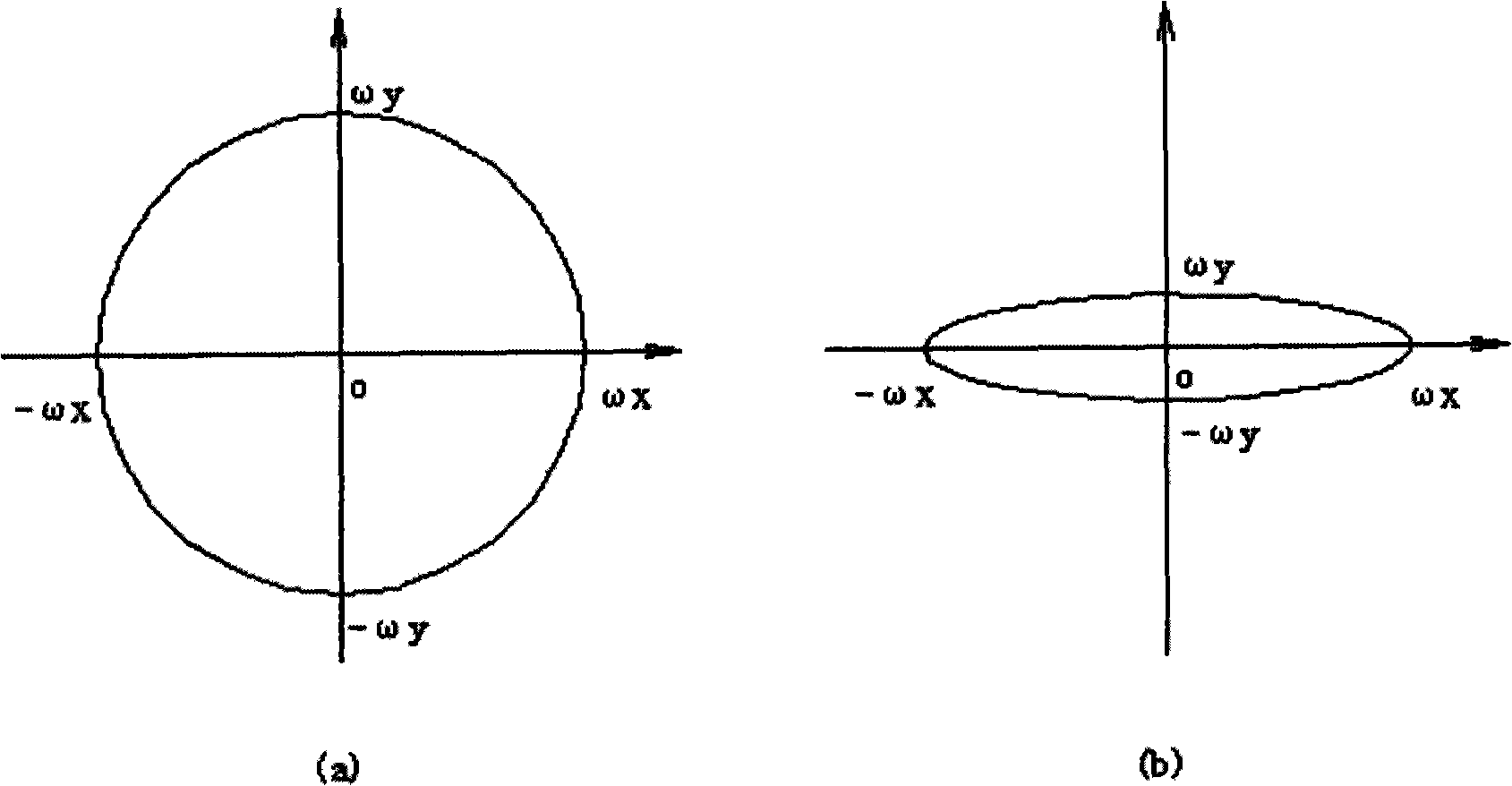

2x2MEMS optical switch based on double-optical fiber ellipse light spot collimator

An elliptical spot and collimator technology, applied in the coupling of optical waveguides, optics, instruments, etc., can solve the problems that MEMS are difficult to achieve, the travel of MEMS micromirrors is large, and the radius of the spot is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

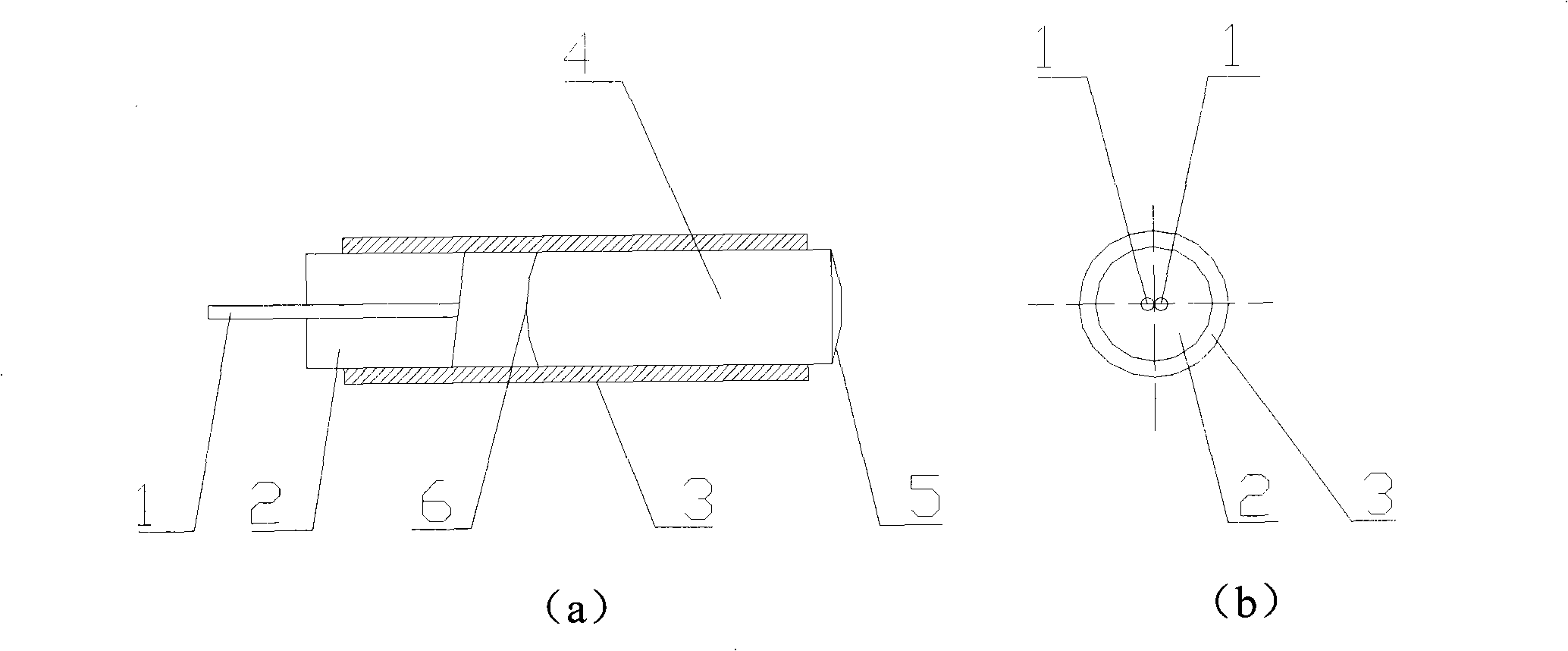

[0037] (1) Installation and commissioning of the dual-fiber elliptical spot collimator (C-lens): figure 2 As shown in the figure, install the collimating lens and the double-fiber head with an 8-degree bevel in the glass tube, adjust the position and fix it with glue.

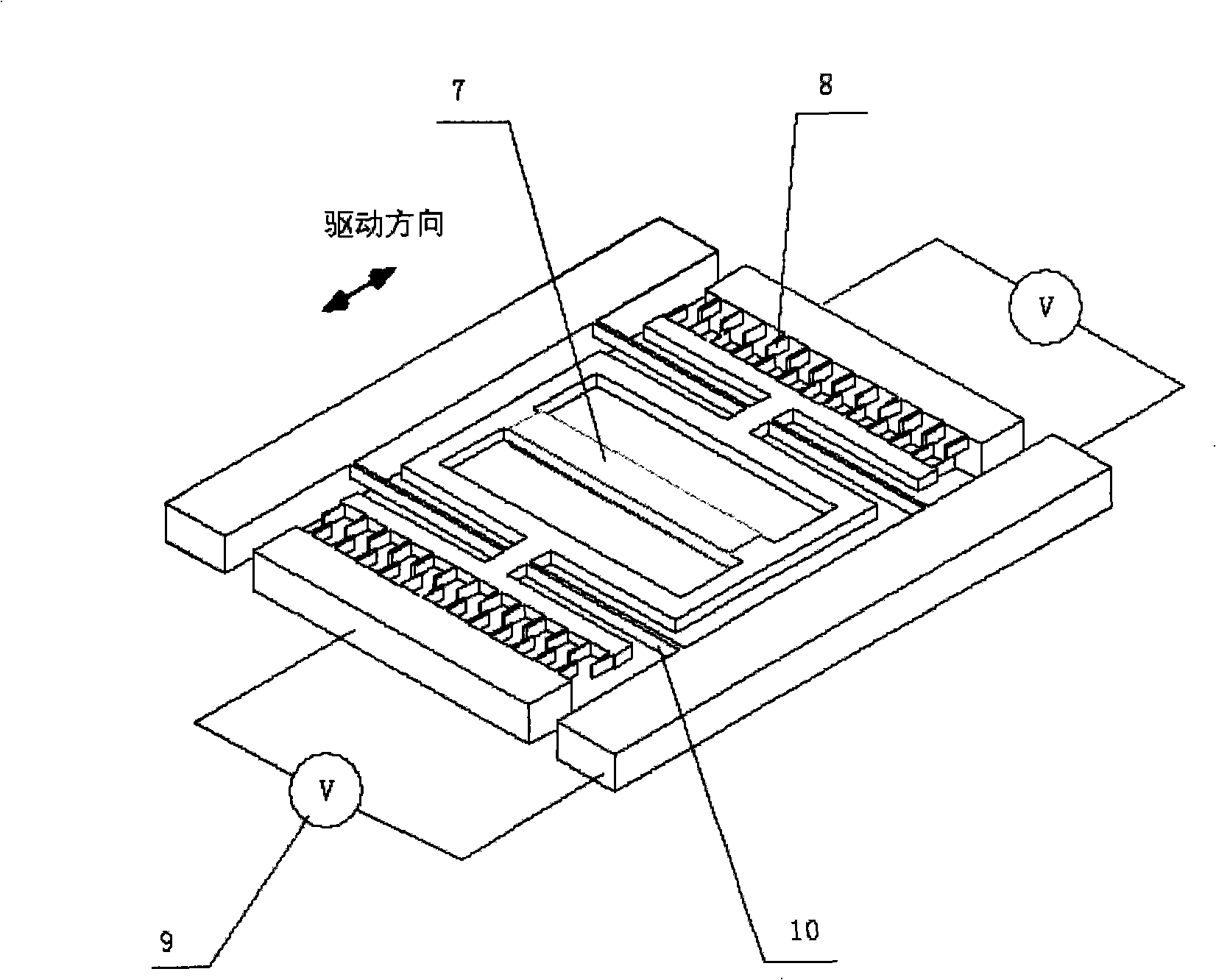

[0038] (2) Fabrication of MEMS comb-driven micromirrors: First, lithography is applied on a silicon substrate, and then a window is etched or etched; Cr-Au is sputtered to make a mirror reflection layer and electrodes; the back is thinned and polished After coating photolithography, micromirrors and comb structures are etched, such as Figure 4 .

[0039] (3) Installation and commissioning of the optical switch: install the two double-fiber elliptical spot collimators and the MEMS micromirror in the sleeve, adjust the position and fix it with glue, such as Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com