Motor-pump assembly for household appliances

A technology for household appliances and electric pumps, applied in electric components, electrical components, machines/engines, etc., to achieve the effect of large heat exchange area and effective heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

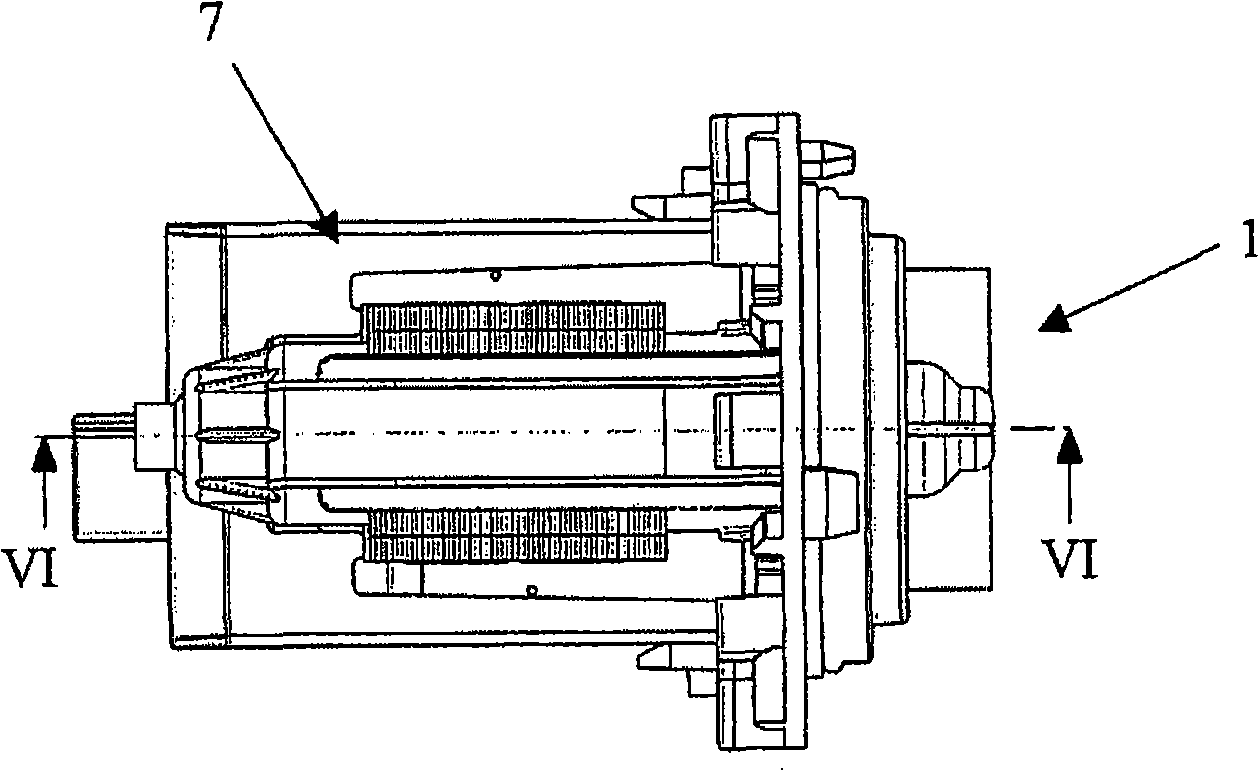

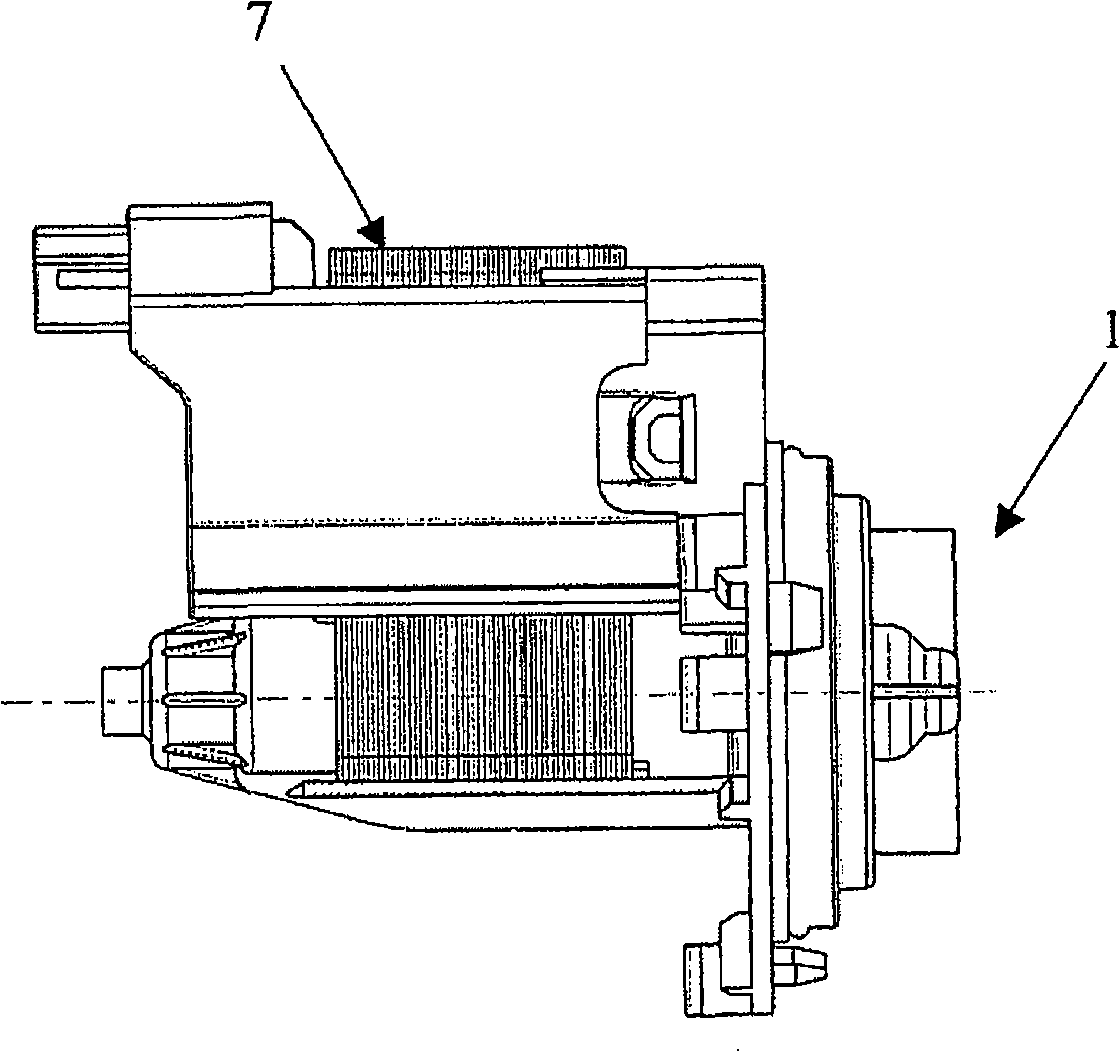

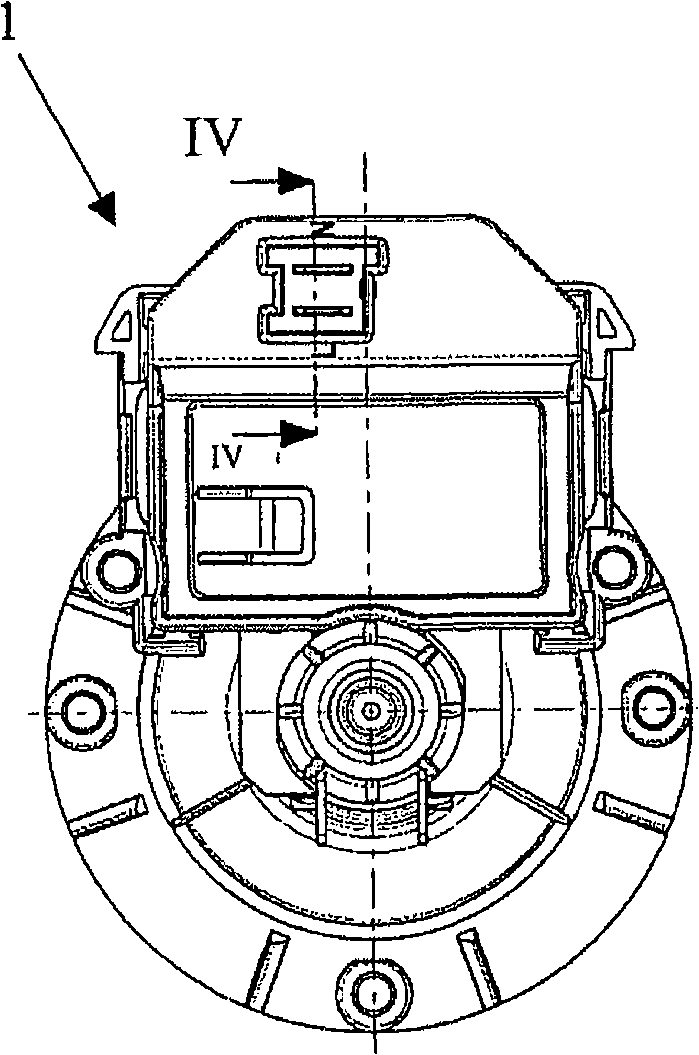

[0027] refer to Figure 1-7 , shows the electric pump assembly 1 of the present invention. The electric pump assembly 1 is made up of a pump body and a one-way synchronous motor 7, wherein the pump body only clearly shows the impeller, because other components have no effect on clearly describing the present invention, and the one-way synchronous motor has a permanent magnet Internal rotor.

[0028] The impeller 2A is connected to the rotor 3 of the single-phase synchronous motor 7 through a shaft 2B. An overmould 3A is fixedly connected to said rotor 3 . The impeller 2A, shaft 2B, rotor 3 and overmold 3A can rotate coaxially.

[0029] It can be seen that the bearings 9, 10 support the shaft 2B, and thus the rotor 3, in such a way that they can rotate.

[0030] The rotor 3 is a permanent magnet. The rotor is separated by an air gap 4 from a tuning-fork-type (sometimes called fork-type) stator 5, which is a ferromagnetic core. The stator 5 is formed by stacking U-shaped l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com