Method for absorbing sulfur dioxide in sintering flue gas using blast furnace smoke as absorbing agent

A technology of sulfur dioxide and sintering flue gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve problems such as reducing the service life of blast furnaces, nodules on the upper part of the furnace body, and upturning of blast furnace tuyeres to reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

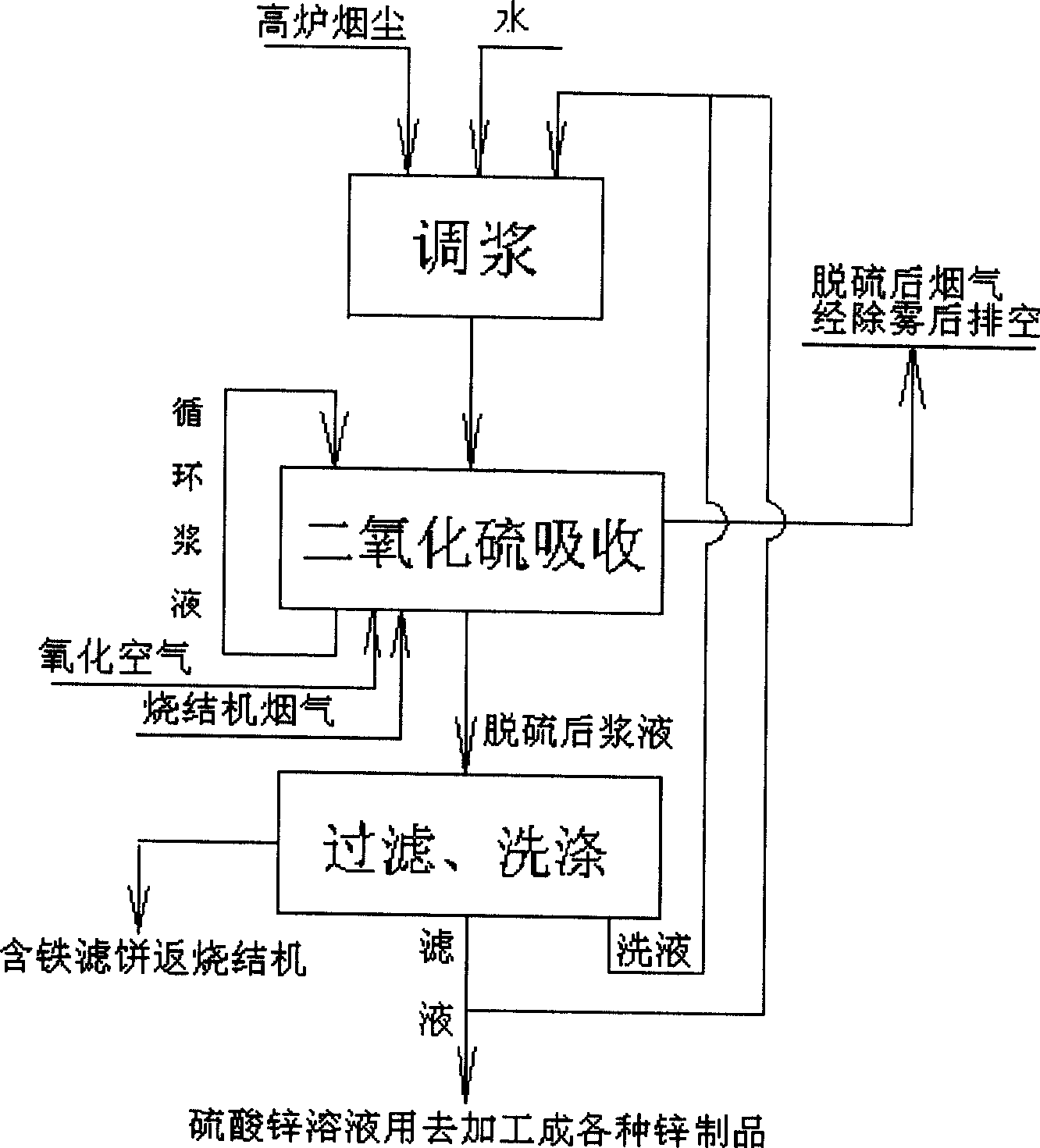

[0028] Such as figure 1 As shown, the blast furnace dust is prepared into a blast furnace dust "slurry" with a mass concentration of 5% to 20% in the slurry mixing tank with water and the returned lotion and filtrate in the filtering and washing process.

[0029] The specific method of pulping is to pump the lotion and filtrate from the corresponding liquid storage tanks to the pulping tank respectively to reach the predetermined scale position. When there is no washing liquid at the beginning and the filtrate is returned, or the amount of washing liquid and filtrate is not enough, add water to supplement.

[0030] The blast furnace dust is quantitatively added to the slurry mixing tank through the screw feeder through the storage hopper, and under the action of the mixer, it is prepared together with the liquid in the tank to form a blast furnace dust "slurry" with a concentration of 5% to 20% by mass. Slurry adjustment is discontinuous operation. Two slurry adjustment tanks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com