Nano carbon tube cluster power and preparation

A carbon nanotube and cluster technology, applied in the field of materials, can solve the problems of low preparation efficiency, low preparation efficiency and high preparation cost, and achieve the effects of thin tube wall, uniform diameter and large inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Prepare 0.5mol / l Fe(NO 3 ) 3 Aqueous solution, measure 10ml and mix with 15g of SiO 2 Mix the powder evenly, bake in a muffle furnace at 500°C for 60 minutes, and use it as a catalyst after grinding.

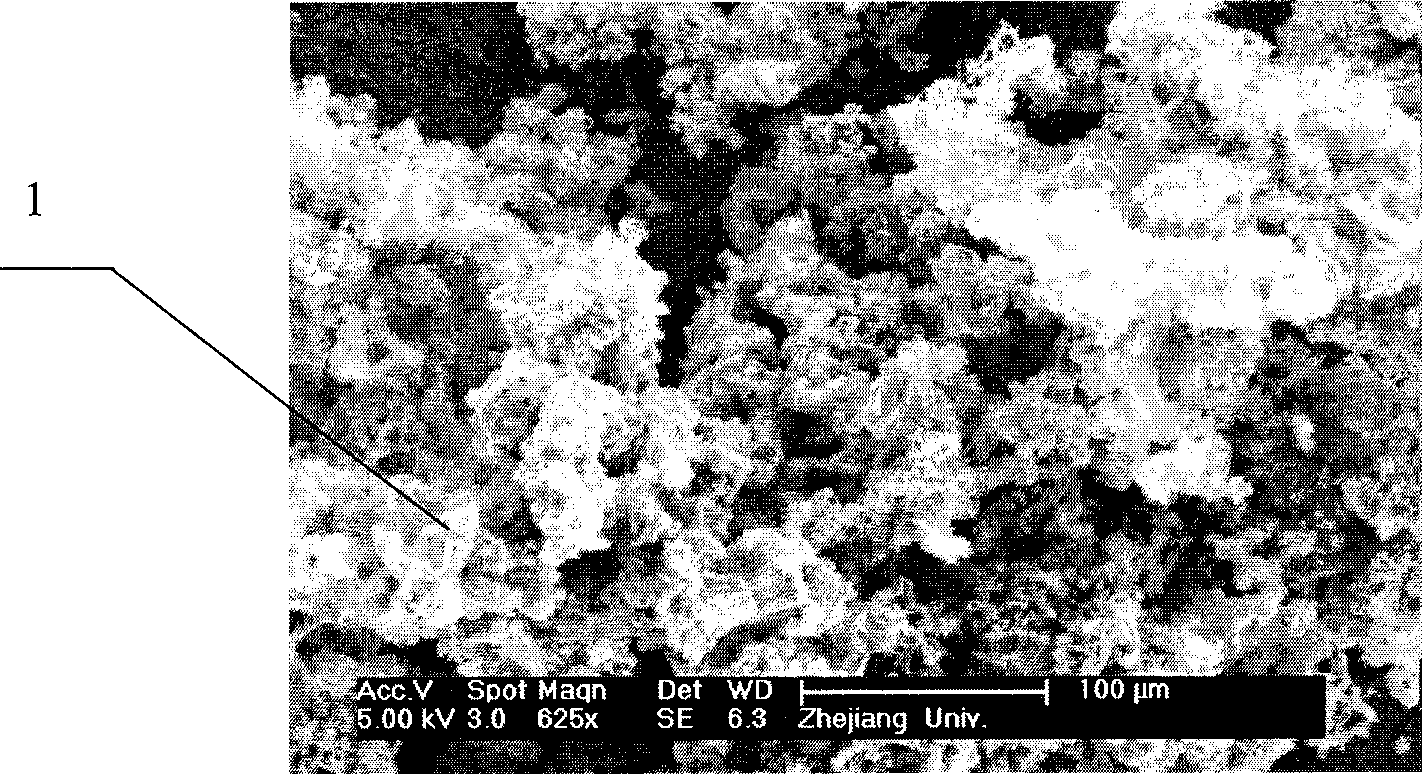

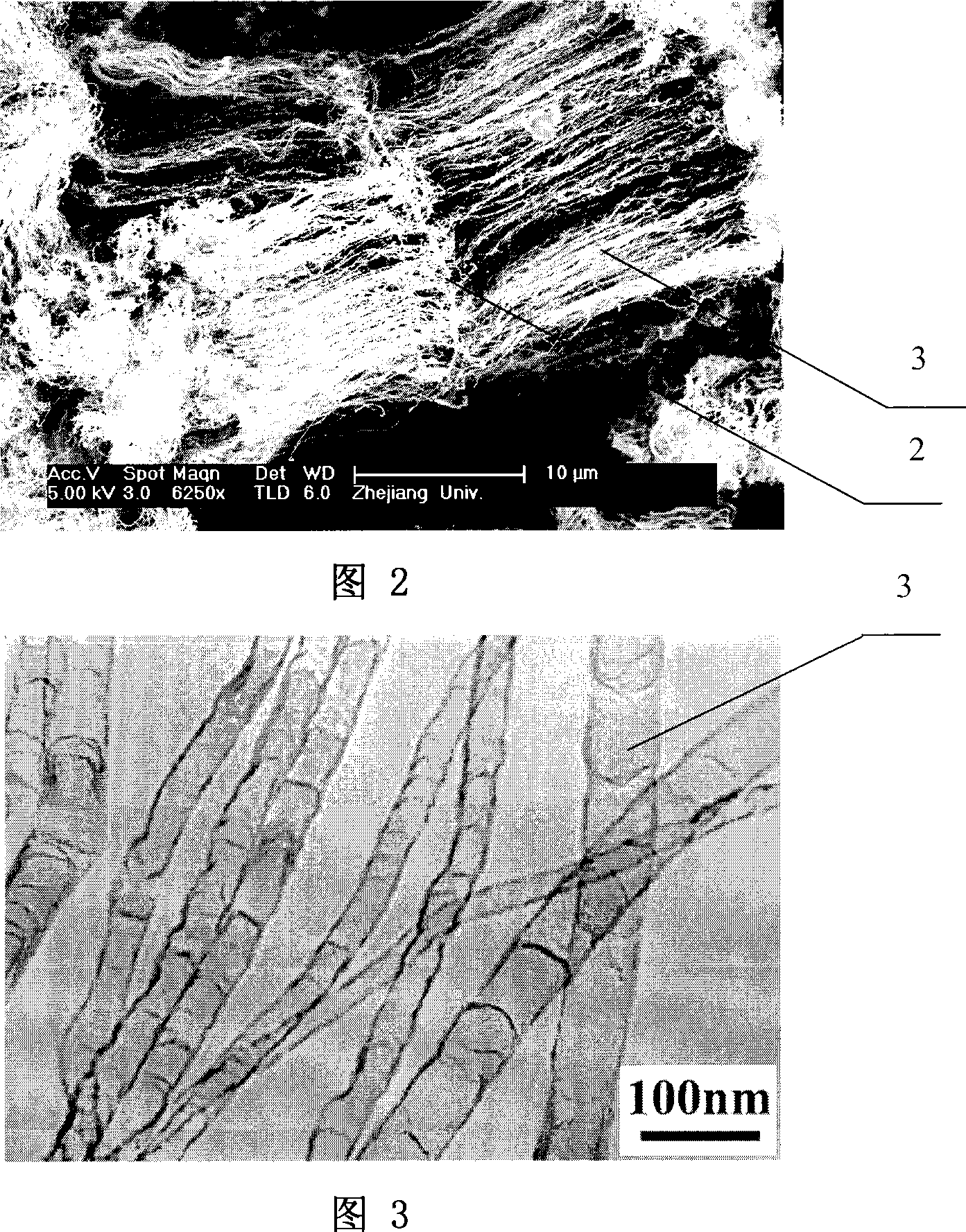

[0019] The furnace was heated to 900°C and filled with N 2 emptying. Put the catalyst in the quartz boat and push it into the reaction zone. When the temperature reaches 900°C again and maintain a constant temperature, the flow rate is 100cm 3 / min, 300cm 3 / min, 40cm 3 N / min 2 , NH 3 and C 2 h 2 of the gas mixture. After holding for 10 minutes, at N 2 Take it out after cooling to room temperature under the protection of the hood, and obtain a carbon nanotube cluster powder with microscopic orientation.

Embodiment 2

[0021] Prepare 1.2mol / l Co(NO 3 ) 2 Aqueous solution, measure 10ml and mix with 15g of Si powder evenly, bake in muffle furnace at 800°C for 10 minutes, grind and use as catalyst.

[0022] The furnace was heated to 800°C and filled with N 2 emptying. Put the catalyst in the quartz boat, push it into the reaction zone, wait for the temperature to reach 800°C again and keep it at a constant temperature, the flow rate is 50cm 3 / min, 100cm 3 / min, 20cm 3 N / min 2 , NH 3 and C 2 h 2 of the gas mixture. After holding for 60 minutes, at N 2 Take it out after cooling to room temperature under the protection of the hood, and obtain a carbon nanotube cluster powder with microscopic orientation.

Embodiment 3

[0024] Prepare 3mol / l Ni(NO 3 ) 2 Aqueous solution, measure 10ml and mix with 15g of Al 2 o 3 Mix the powder evenly, bake in a muffle furnace at 600°C for 40 minutes, and use it as a catalyst after grinding.

[0025] The furnace was heated to 700°C and filled with N 2 emptying. Put the catalyst in the quartz boat, push it into the reaction zone, wait for the temperature to reach 700°C again and keep it at a constant temperature, the flow rate is 200cm 3 / min, 500cm 3 / min、60cm 3 N / min 2 , NH 3 and C 2 h 2 of the gas mixture. After holding for 120 minutes, at N 2 Take it out after cooling to room temperature under the protection of the hood, and obtain a carbon nanotube cluster powder with microscopic orientation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com