Technique for reclaiming waste water of azoic dye production

An azo dye and wastewater recycling technology, which is applied in the fields of neutralization water/sewage treatment, aerobic and anaerobic process treatment, natural water treatment, etc. It can solve the problems of polluted environment, unrecycled wastewater, and damage to the ecological environment of water bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

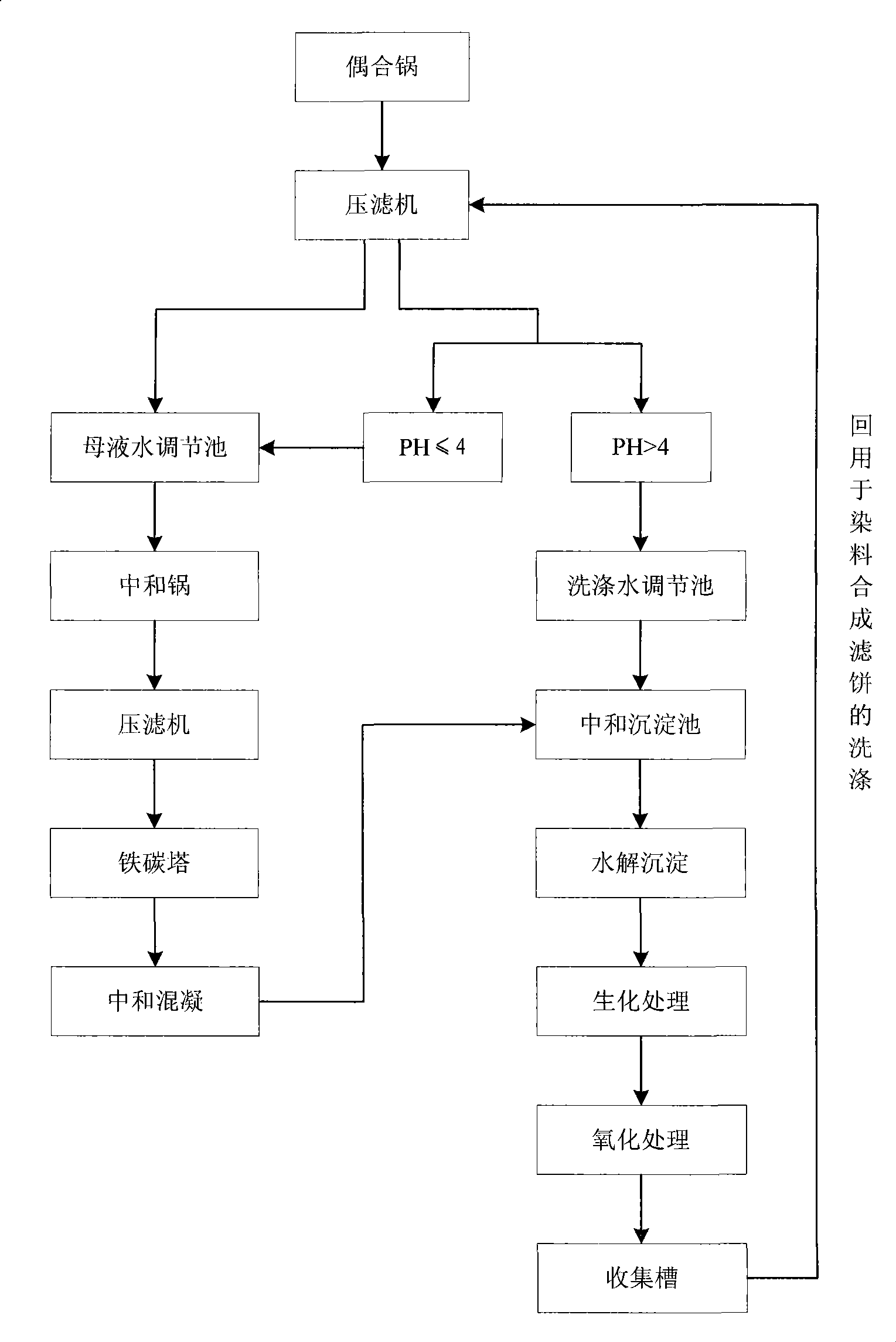

Method used

Image

Examples

Embodiment 1

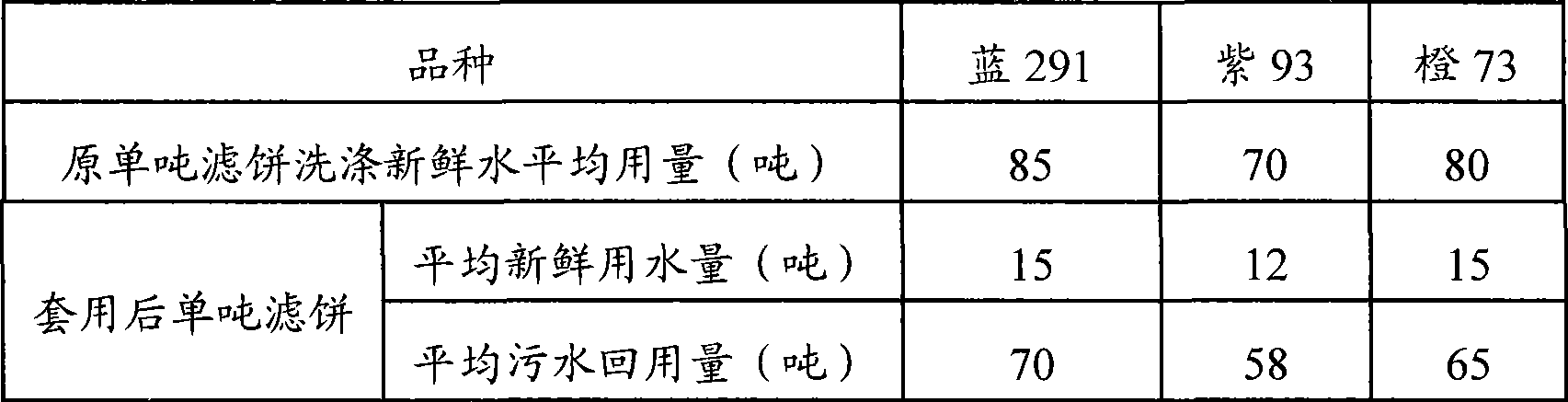

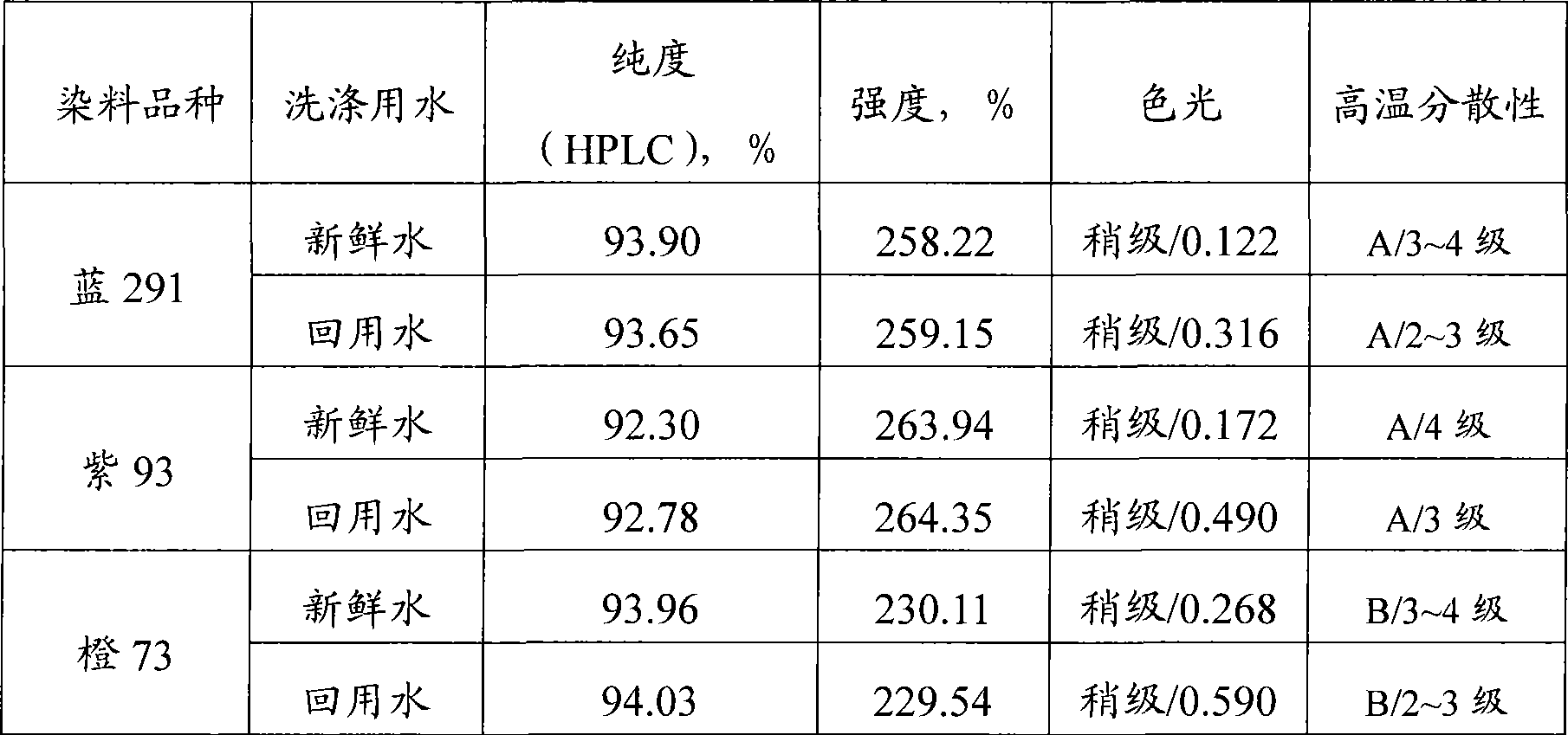

[0015] (1) Preparation of C.I. Disperse Blue 291

[0016] Add 1176kg of 98% sulfuric acid and 280kg of nitrosyl sulfuric acid solution into the reactor, and slowly add 524kg of sulfuric acid. 2,4-Dinitro-6-bromoaniline, stir to dissolve, control the temperature at about 25°C for reaction, use starch potassium iodide test paper to indicate the end point to prepare diazonium salt. The above-prepared diazonium salt is slowly added to the 473kg 2-methoxy-5-acetamido-N,N-diethylaniline suspension for coupling reaction, and the coupling temperature is controlled to 0~ The coupling reaction was carried out at 5°C. After the reaction was completed, the coupling liquid was suction filtered, and at the same time, about 85 tons of fresh water was used to wash to neutrality, and the material was discharged to obtain CI Disperse Blue 291 filter cake.

[0017] (2) Treatment and recovery of mother liquor water and washing water

[0018] Collect the mother liquor water of the CI Disperse Blue 291...

Embodiment 2

[0025] According to the preparation method described in Example 1, the difference is:

[0026] In step (1), replace 473 kg of 2-methoxy-5-acetamido-N,N-diethylaniline suspension with 413 kg of 3-acetamido-N,N-diethylaniline suspension. 70 tons of fresh water replaces 85 tons of fresh water to wash the dye filter cake;

[0027] In step (2), replace C.I. Disperse Blue 291 with C.I. Disperse Violet 93;

[0028] In step (3), 12 tons of fresh water and 58 tons of recycled water were used instead of 70 tons of fresh water in step (1) of Example 2 to wash the filter cake to neutrality to obtain a C.I. Disperse Violet 93 filter cake.

Embodiment 3

[0030] (1) Preparation of C.I. Disperse Orange 73

[0031] Add 1225 kg of 98% sulfuric acid solution and 333 kg of nitrosyl sulfuric acid solution into the reaction kettle, slowly add 345 kg of p-nitroaniline, stir to dissolve, and control the temperature at about 15°C for reaction. Use starch potassium iodide test paper to indicate the end point. Get p-nitroaniline diazonium salt. Slowly add the prepared diazonium salt to 735kg N-cyanoethyl-N-benzoyloxyethylaniline suspension, control the coupling temperature below 15°C, and stir for about 6 hours, then The temperature was raised to about 60°C, and the temperature was kept stirring for 2 hours. The coupling mother liquor was press-filtered, and the coupling material was washed to neutrality with 80 tons of fresh water, and the material was discharged to obtain the dye CI dispersion orange 73 filter cake.

[0032] (2) Treatment and recovery of mother liquor water and washing water

[0033] Collect the mother liquor water of the CI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com