Special explosive for explosively welding noble metal composite material and preparation thereof

A composite material, explosive welding technology, applied in explosives and other directions, can solve the problems of bonding interface melting, low composite rate and interface bonding strength of precious metal composite materials, and can not meet the requirements of use, etc., to achieve high interface bonding rate and bonding strength, The effect of simple manufacturing method and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

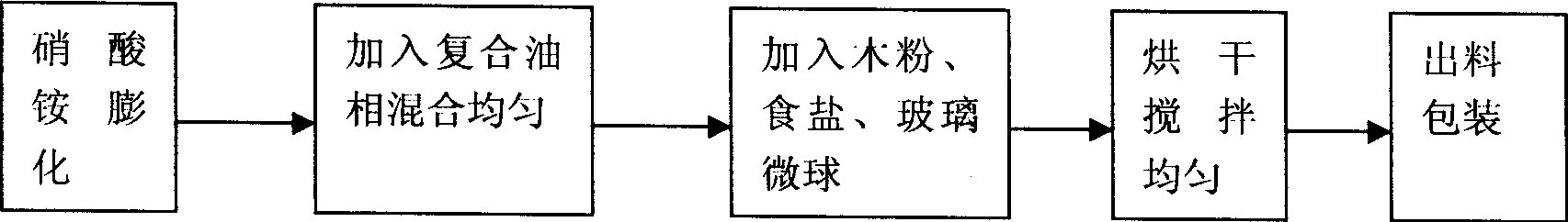

Method used

Image

Examples

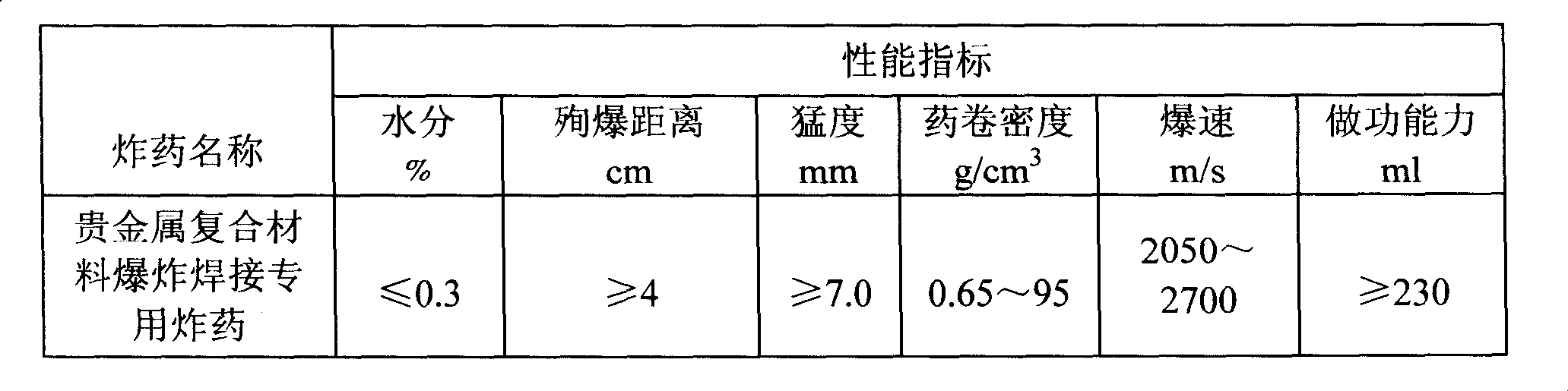

Embodiment 1

[0017] Taking industrial production of 1000kg precious metal composite explosive welding special explosive as an example, the selected components and mass ratio are: ammonium nitrate 75%, composite oil phase 3.5%, wood flour 3.5%, salt 15%, 60 mesh hollow glass microspheres 3.0 %, wherein the composition and mass ratio of the composite oil phase are: 30% diesel oil, 30% 32# common machine oil, and 40% paraffin. According to the above-mentioned components and formula, the implementation steps are: the first step: take 750kg ammonium nitrate and carry out expansion treatment to obtain expanded ammonium nitrate; the second step: take 10.5kg diesel oil, 10.5kg machine oil and 14kg paraffin heating Become composite oil phase; the 3rd step: take by weighing 35kg wood flour, 150kg salt, 30kg hollow glass microspheres and the first step and the expanded ammonium nitrate that the second step makes and composite oil phase mix in wheel mill; The fourth step: cool the material prepared in...

Embodiment 2

[0019] Taking the industrial production of 1000kg precious metal composite material explosion welding special explosive as an example, the selected components and mass ratio are: ammonium nitrate 64%, composite oil phase 2%, wood flour 2.5%, salt 30%, 80 mesh hollow glass microspheres 1.5 %, wherein the composition and mass ratio of the composite oil phase are: 50% diesel oil, 20% 46# common machine oil, and 30% paraffin. According to the above components and formula, the implementation steps are: first step: weigh 640kg of ammonium nitrate and carry out expansion treatment to obtain expanded ammonium nitrate; second step: weigh 10kg of diesel oil, 4kg of machine oil and 6kg of paraffin and heat to make a compound Oil phase; the third step: take by weighing 25kg wood flour, 300kg salt, 15kg hollow glass microspheres and the first step and the second step made expanded ammonium nitrate and composite oil phase are mixed in the wheel mill; the fourth Step 1: Cool the material pre...

Embodiment 3

[0021] Taking the industrial production of 1000kg precious metal composite material explosion welding special explosive as an example, the selected components and mass ratio are: ammonium nitrate 70%, composite oil phase 2.5%, wood powder 3.0%, salt 22%, 80 mesh hollow glass microspheres 2.5% %, wherein the composition and mass ratio of the composite oil phase are: 35% of diesel oil, 15% of 68# common machine oil, and 50% of paraffin wax. According to the above components and formula, the implementation steps are: the first step: take 700kg ammonium nitrate and carry out expansion treatment to obtain expanded ammonium nitrate; the second step: take 8.75kg diesel oil, 3.75kg machine oil and 12.5kg paraffin wax heating, Composite oil phase is made; the third step: take 30kg of wood powder, 220kg of salt, 25kg of hollow glass microspheres and the first and second steps of the obtained expanded ammonium nitrate and composite oil phase and mix them in the wheel mill Uniformity; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com