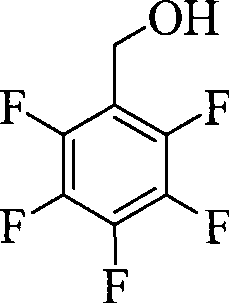

Preparation of 2,3,4,5,6-pentafluorobenzyl alcohol

A technology of pentafluorobenzyl alcohol and pentafluorobenzonitrile is applied in 2 fields, can solve the problems of high price, corrosion of production equipment, low temperature, etc., and achieves the effects of low cost of raw materials, reduced pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

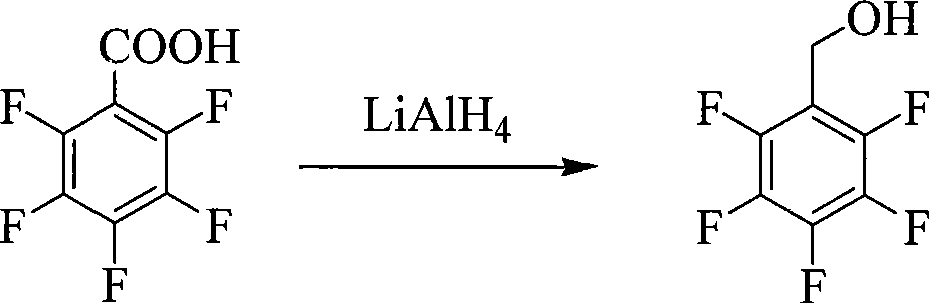

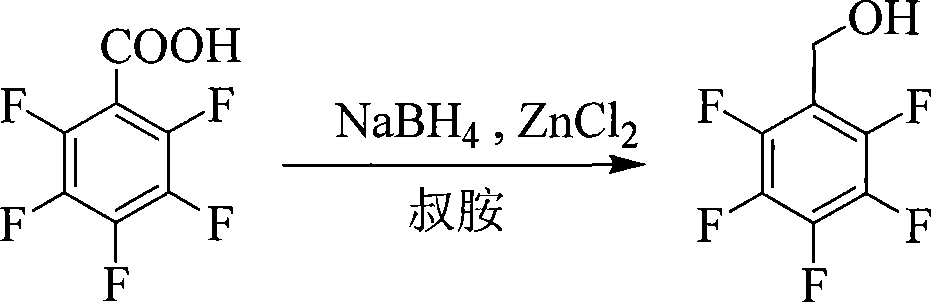

Method used

Image

Examples

Embodiment 1

[0043] Weigh 20.0g of pentafluorobenzonitrile, 0.8g of RTH-312 type Raney-Ni (produced by Datong General Chemical Co., Ltd.), 80mL of methanol, and 11.7g of concentrated sulfuric acid into a 250mL autoclave, replace the gas with nitrogen three times, and pass through H 2 The pressure was 15 atm, the temperature was raised to 55°C, and after 13 hours of reaction, sampling and analysis were performed, the raw materials disappeared, the insoluble matter was filtered out, and the solvent was evaporated under reduced pressure to obtain 28.7 g of sulfate salt of pentafluorobenzylamine, content: 98.6% (HPLC) , Yield: 93.8%.

Embodiment 2

[0045] Weigh 20.0g of pentafluorobenzonitrile, 0.15g of 10% Pb / C (produced by Baoji Ruike Pharmaceutical Chemical Co., Ltd.), 55mL of ethanol, and 14.1g of oxalic acid into a 250mL autoclave, replace the gas with nitrogen three times, and pass through H 2 The pressure was 10 atm, the temperature was raised to 55°C, and after 14 hours of reaction, sampling and analysis were performed, the raw materials disappeared, the insoluble matter was filtered out, and the solvent was recovered under reduced pressure to obtain 28.1 g of oxalate of pentafluorobenzylamine, content: 98.8% (HPLC) , Yield: 94.2%.

Embodiment 3

[0047] Weigh 26.0g of pentafluorobenzonitrile, 1.2g of RTH-6120 Raney-Co (manufactured by Datong General Chemical Co., Ltd.), 65mL of DMF, and 19.2g of trifluoroacetic acid into a 250mL autoclave, replace the gas with nitrogen three times, and pass H2 To a pressure of 20atm, the temperature was raised to 58°C. After reacting for 15 hours, a sample was analyzed. The raw material disappeared, and the insoluble matter was filtered out. The solvent was recovered under reduced pressure to obtain 39.4 g of trifluoroacetate of pentafluorobenzylamine, content: 98.7% ( HPLC), yield: 94.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com