Ecological environment protection type pavement tile and producing process thereof

An environment-friendly, trail-based technology, applied to roads, roads, manufacturing tools, etc., can solve the problems of reduced durability, unreasonable brick structure design, and slow water permeability, so that the degree of resistance to rolling is not reduced, and it is convenient for production and The effect of popularizing and increasing the content of negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

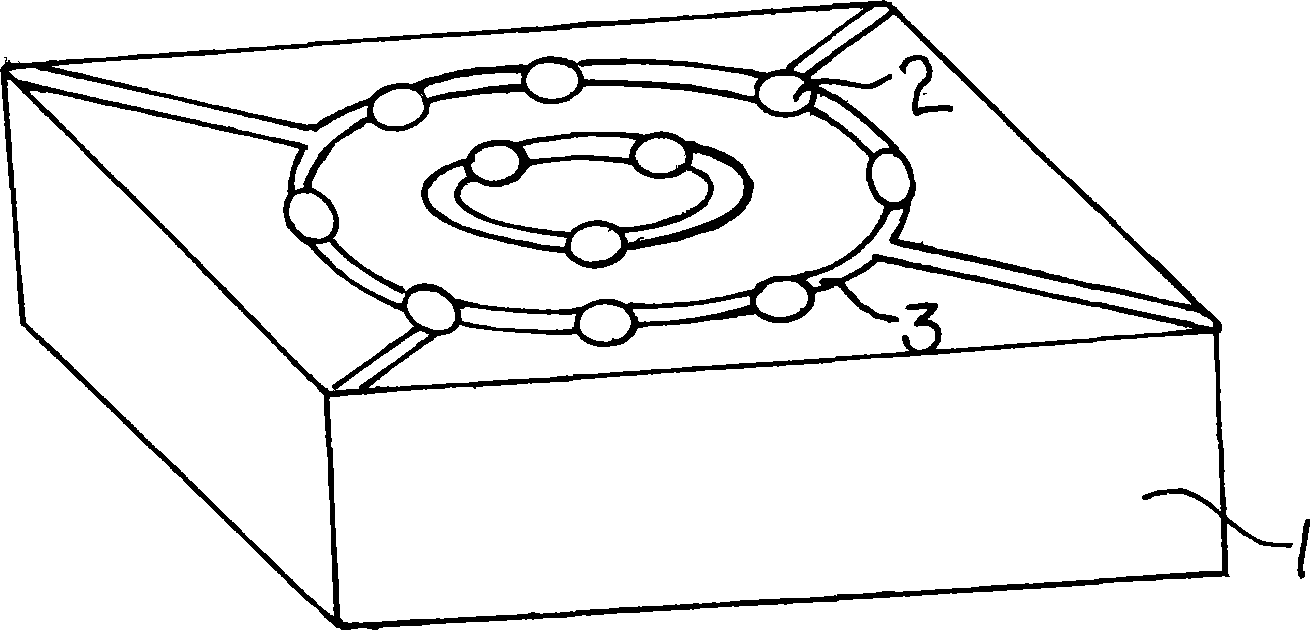

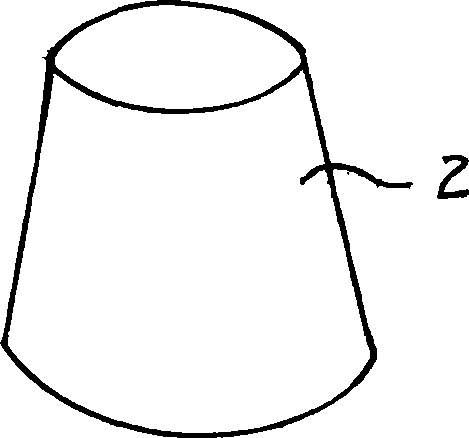

[0045] Such as figure 1 As shown, the ecological environment-friendly pavement brick includes a brick body 1; a groove 3 is provided on the upper surface of the brick body 1; a through hole 2 is longitudinally provided at the position of the groove 3 of the brick body 1. Such as figure 2 As shown, the through hole 2 in the present invention has a frustoconical structure. The groove 3 is two closed annular grooves. There are 20 through holes 2 .

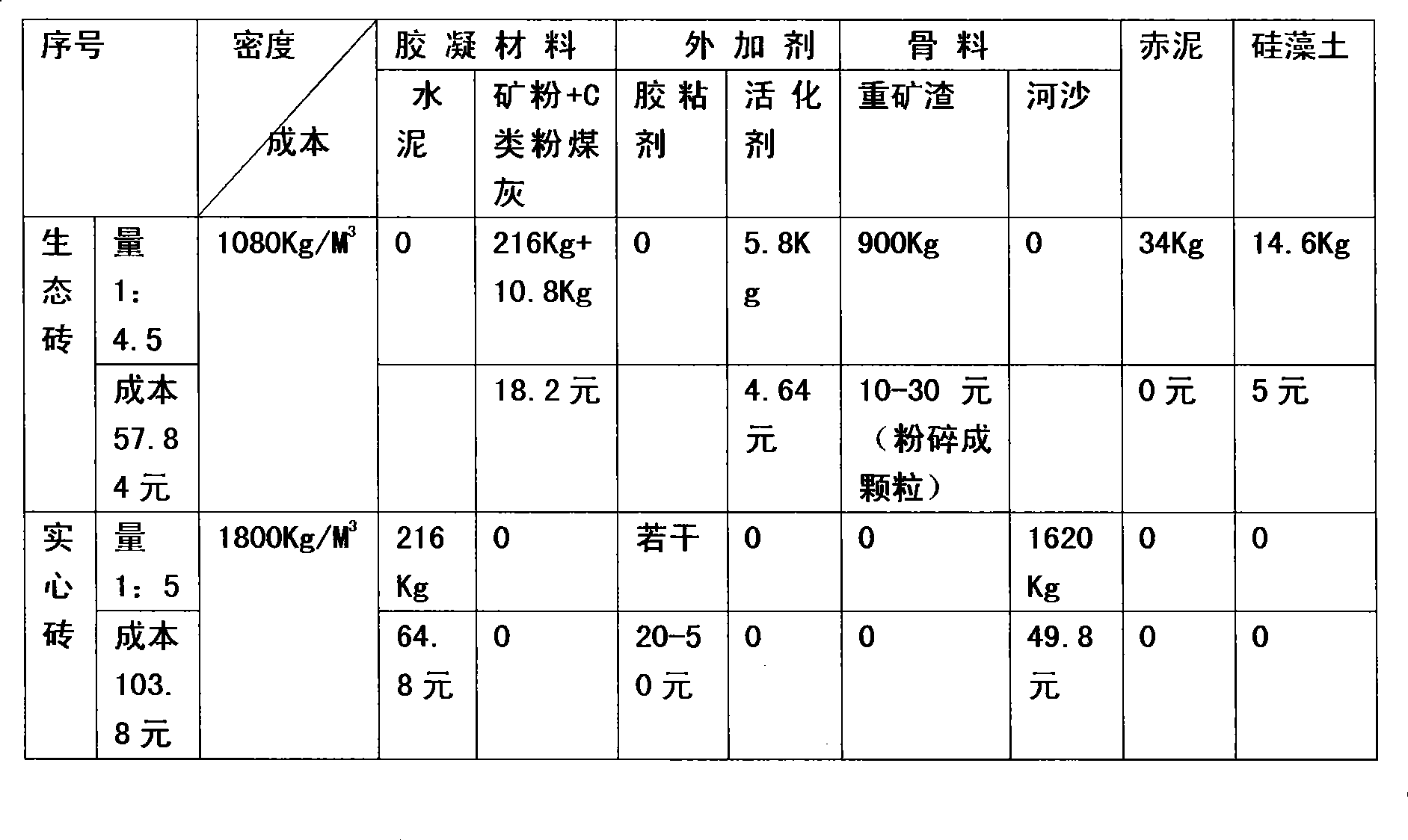

[0046] The materials used in the brick body 1 of the present invention include cementitious materials, aggregates and activators; the cementitious materials contain slag powder, red mud, class C fly ash and diatomite; the aggregates are waste slag particles ; The activator contains polycarboxylate water reducer, power plant desulfurization gypsum, aluminum sulfate slag and fly ash. The weight ratio of slag micropowder, red mud, class C fly ash and diatomite in the cementitious material is 60kg: 5kg: 7kg: 1kg; the particle diamete...

Embodiment 2

[0056] Such as figure 1 As shown, the ecological environment-friendly pavement brick includes a brick body 1; a groove 3 is provided on the upper surface of the brick body 1; a through hole 2 is longitudinally provided at the position of the groove 3 of the brick body 1. The through hole 2 is a circular frustum structure. The groove 3 is three closed annular grooves. There are 24 through holes 2 .

[0057] The materials used in the brick body 1 of the present invention include cementitious materials, aggregates and activators; the cementitious materials contain slag powder, red mud, class C fly ash and diatomite; the aggregates are waste slag particles ; The activator contains polycarboxylate water reducer, power plant desulfurization gypsum, aluminum sulfate slag and fly ash. The weight ratio of slag micropowder, red mud, class C fly ash and diatomite in the cementitious material is 90kg: 9kg: 15kg: 5kg; the particle diameter d of the waste slag particles is 7mm; The weig...

Embodiment 3

[0067] The ecological environment-friendly pavement brick comprises a brick body 1; a groove 3 is arranged on the upper surface of the brick body 1; a through hole 2 is longitudinally arranged at the position of the groove 3 of the brick body 1. The through hole 2 is a circular frustum structure. The groove 3 is three closed annular grooves. There are 18 through holes 2 .

[0068] The materials used in the brick body 1 of the present invention include cementitious materials, aggregates and activators; the cementitious materials contain slag powder, red mud, class C fly ash and diatomite; the aggregates are waste slag particles ; The activator contains polycarboxylate water reducer, power plant desulfurization gypsum, aluminum sulfate slag and fly ash.

[0069] The weight ratio of slag micropowder, red mud, C-type fly ash and diatomite in the cementitious material of the present invention is 80kg: 7kg: 10kg: 3kg; the particle diameter d of the waste slag particles is 7mm; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com