Hybrid plastic runway and its construction method

A plastic runway and construction method technology, which is applied to roads, roads, pavements, etc., can solve problems such as surface particle threshing, achieve good firmness, prolong service life, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

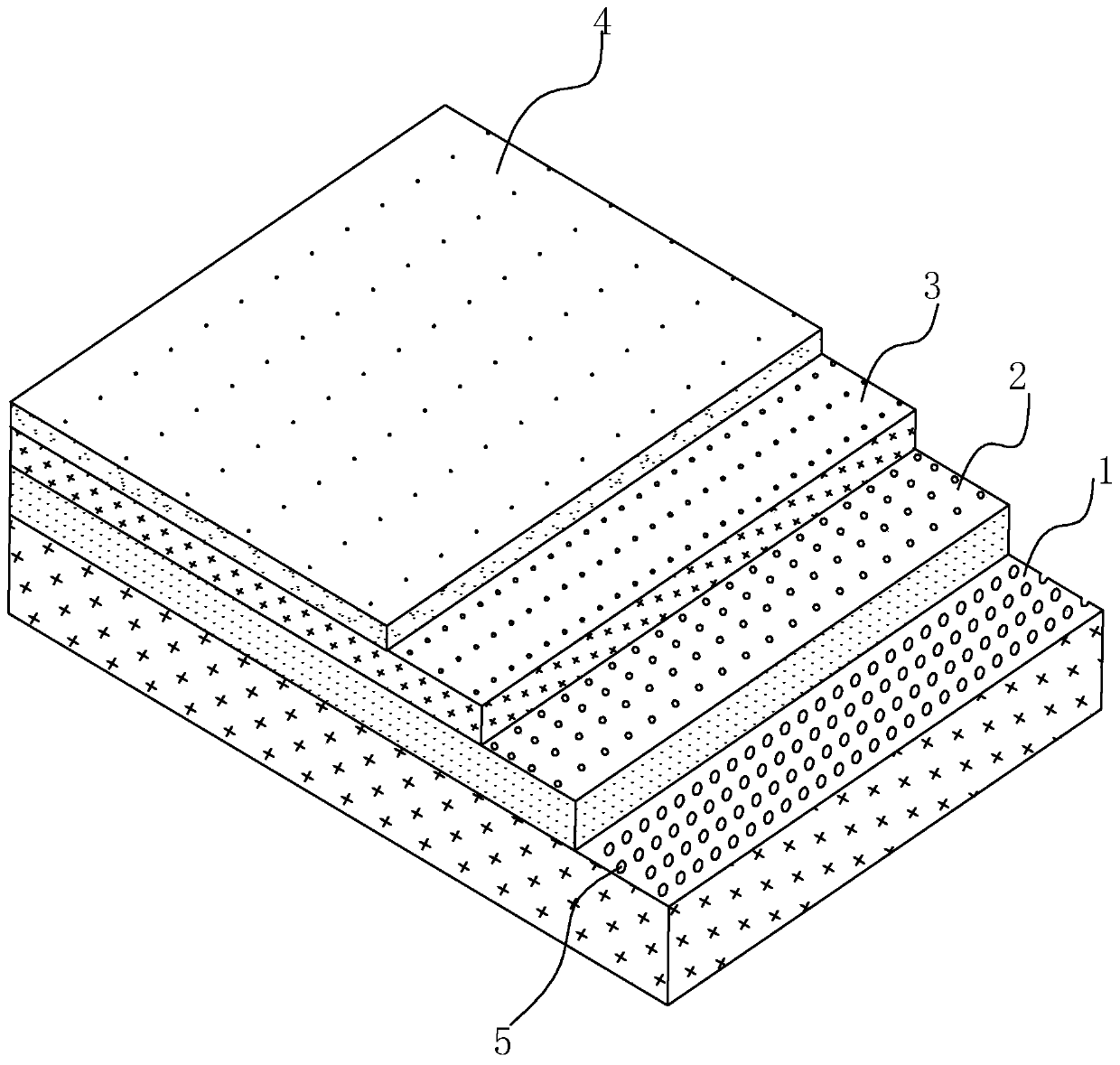

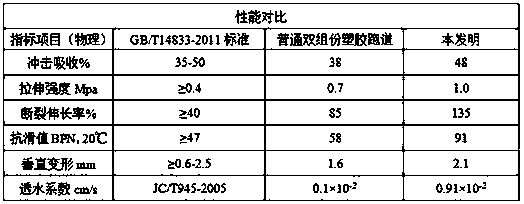

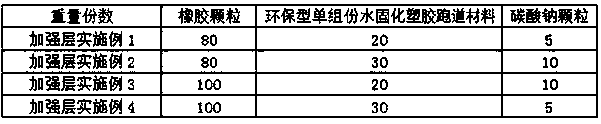

[0076] Attached below figure 1 , tables and examples, the present invention is described in detail.

[0077] Environmentally-friendly one-component water-cured plastic track materials. Water-cured materials can be used to adjust the curing time and flexibility of the material. Compared with the current two-component oily materials on the market, water-cured one-component materials are more environmentally friendly and have lower tensile strength. and higher elongation at break.

[0078] The self-knotting pattern refers to the phenomenon that the non-slip uneven surface of the plastic runway uses special polyurethane pure glue and a polyurethane copolymer formed through physical reaction to automatically generate uneven unevenness in the surface knot state. The texture formed by the self-knotting pattern reaches a certain friction coefficient, meets the anti-wet and slippery indicators, does not drop grains, does not have broken lines, does not require special manual maintenan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com