Single-cylinder circular ring type cylinder internal combustion engine

A circular, internal combustion engine technology, applied in the field of power machinery, can solve the problems of high processing and manufacturing technology of rotary engines, increased fuel and oil consumption, and unfavorable complete combustion, etc., to achieve large torque, reduce pollution, and improve output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

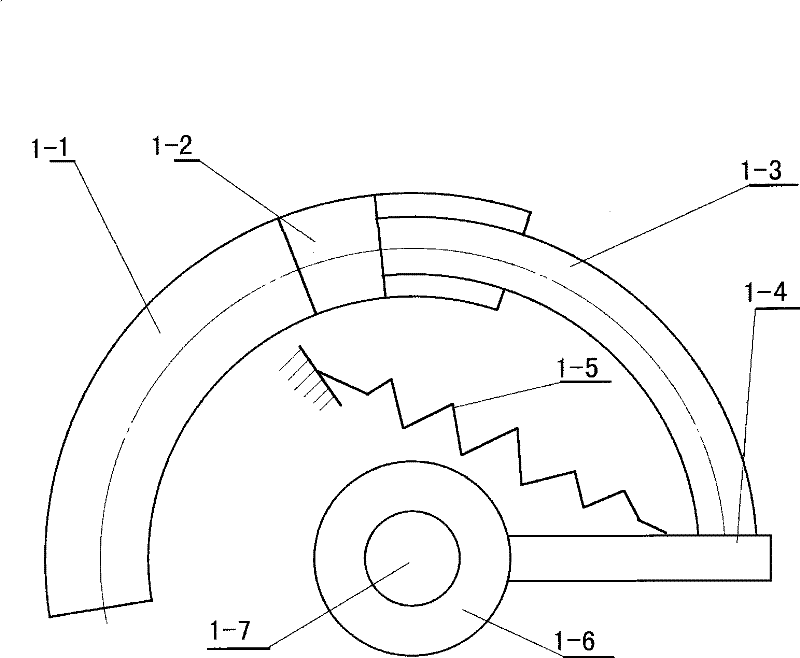

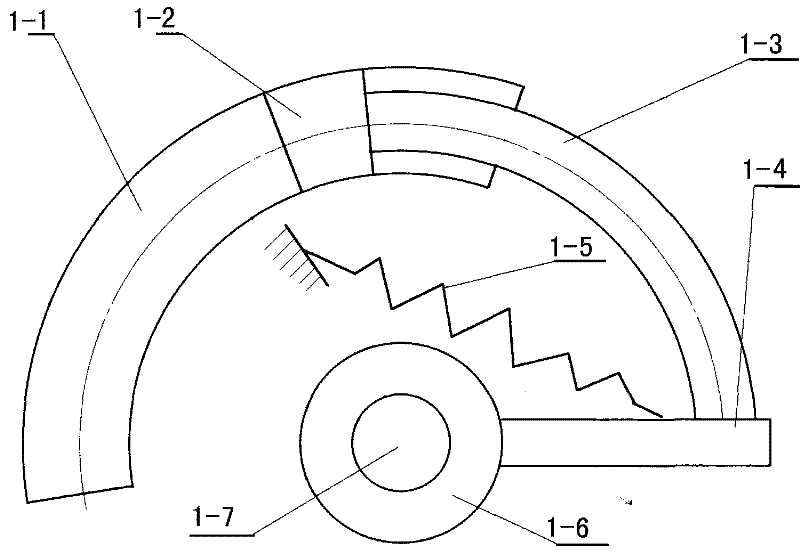

[0019] see figure 1 , it can be seen that the part of the single-cylinder internal combustion engine, the bonding surface between the cylinder 1-1 and the piston 1-2 is two layers of torus inside and outside, the piston 1-2 rotates around the center of the cylinder 1-1, when the combustion mechanism detonates , the expansion gas always pushes the piston 1-2 to rotate tangentially, and the piston 1-2 transmits the rotational torque to the clutch 1-6 through the piston arm 1-3 and the connecting rod 1-4. At this time, the clutch 1-6 and the rotating main shaft 1 -7 is the combined state, turning the main shaft 1-7 to rotate clockwise; when entering the exhaust stage, the speed of the piston 1-2 drops, turning the main shaft 1-7 is faster, and the clutch 1-6 is in a disengaged state, which can avoid The strong vibration of the mechanism plays a protective role; when the exhaust is over, the piston 1-2 stops rotating, and the spring 1-5 acts as a return mechanism, one end of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com