Eye sterile suspension containing loteprednol etabonate and preparation method thereof

A technology of loteprednol etabonate and suspension, applied in the field of ophthalmic sterile suspension, can solve the problem of affecting crystal form and stability, failing to pass through a sterile filter, and not mentioning loteprednol etabonate. Nuo sterilization problems and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

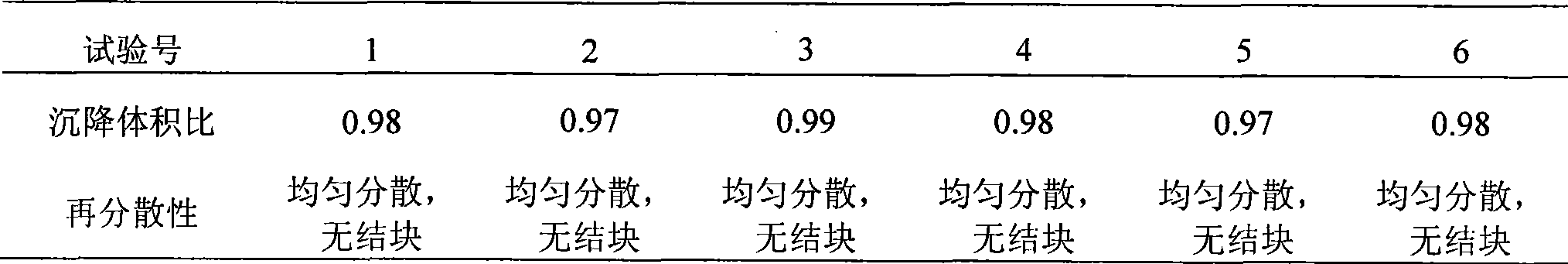

Examples

Embodiment 1

[0017] Loteprednol etabonate 5.0g

[0018] Tobramycin 3.0g

[0019] Glycerin 25.0g

[0020] Hypromellose 3.0g

[0021] Chlorobutanol 5.0g

[0022] Tween-80 2.0g

[0023] Edetate Disodium 0.5g

[0024] Appropriate amount of water for injection

[0025] Makes 1000ml

[0026] Micronized with loteprednol carbonate, sterilized by dry heat at 150°C; hypromellose was swollen with water, sterilized at 121°C for 20 minutes, cooled, and set aside; tobramycin, glycerin, chlorobutanol, Dissolve Tween-80 and edetate disodium in water, filter and sterilize with a 0.22 μm sterile filter membrane, add hypromellose to the aqueous solution, add loteprednol etabonate microcrystals while stirring, stir Evenly, adjust the pH value to 5-6. Subpackage.

Embodiment 2

[0028] Loteprednol etabonate 5.0g

[0029] Tobramycin 3.0g

[0031] Hypromellose 4.0g

[0032] Chlorobutanol 3.0g

[0033] Tween-80 3.0g

[0034] Edetate Disodium 0.6g

[0035] Appropriate amount of water for injection

[0036] Makes 1000ml

[0037] Micronized with loteprednol carbonate, sterilized by dry heat at 160°C; hypromellose was swollen with water, sterilized at 115°C for 30 minutes, cooled, and set aside; tobramycin, sodium chloride, chlorotert-butyl Dissolve alcohol, Tween-80, and edetate disodium in water, filter and sterilize with a 0.22 μm sterile filter membrane, add hypromellose to the aqueous solution, and add loteprednol etabonate microcrystals while stirring , stir well, and adjust the pH value to 5-6. Subpackage.

Embodiment 3

[0039] Loteprednol etabonate 5.0g

[0040] Glycerin 13g

[0041] Sodium chloride 4g

[0042] Hypromellose 2g

[0043] Chlorobutanol 0.6g

[0044] Tween-80 1.0g

[0045] Edetate Disodium 0.3g

[0046] Appropriate amount of water for injection

[0047] Makes 1000ml

[0048]Micronized with loteprednol carbonate, sterilized by dry heat at 160°C; hypromellose was swollen with water, sterilized at 121°C for 20 minutes, cooled, and set aside; glycerin, sodium chloride, chlorobutanol, spit Dissolve Wen-80 and edetate disodium in water, filter and sterilize with a 0.22 μm sterile filter membrane, add hypromellose to the aqueous solution, add loteprednol etabonate microcrystals while stirring, and stir well , adjust the pH value to 5-6.5. Subpackage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com