Low-grade scheelite in molybdenum floatation tailings

A molybdenum tailings, low-grade technology, applied in the field of recovery of low-grade scheelite, can solve the problems of unsatisfactory indicators, low concentrate grade, low total recovery rate, etc., to achieve small footprint and large equipment processing capacity , The effect of high equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

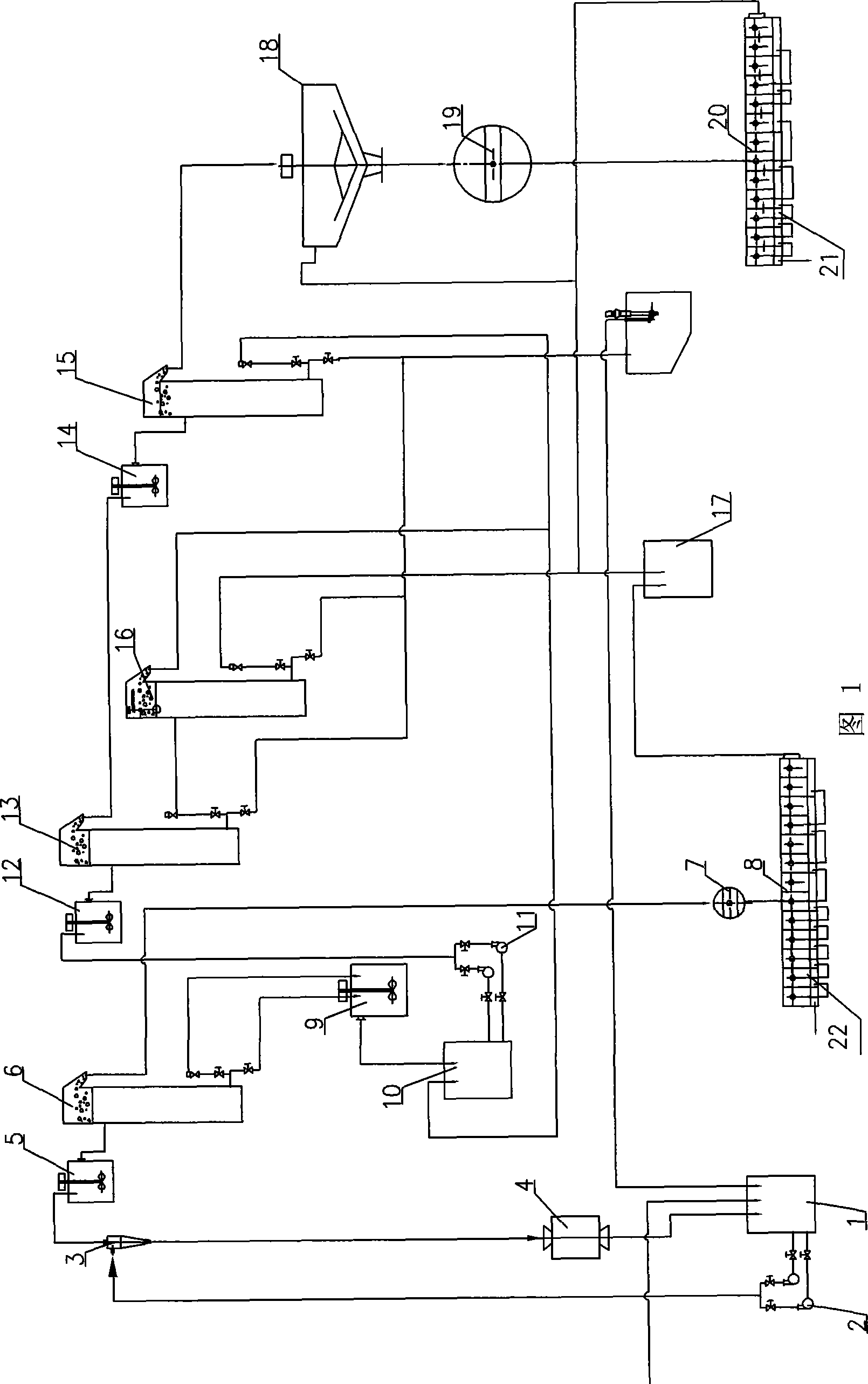

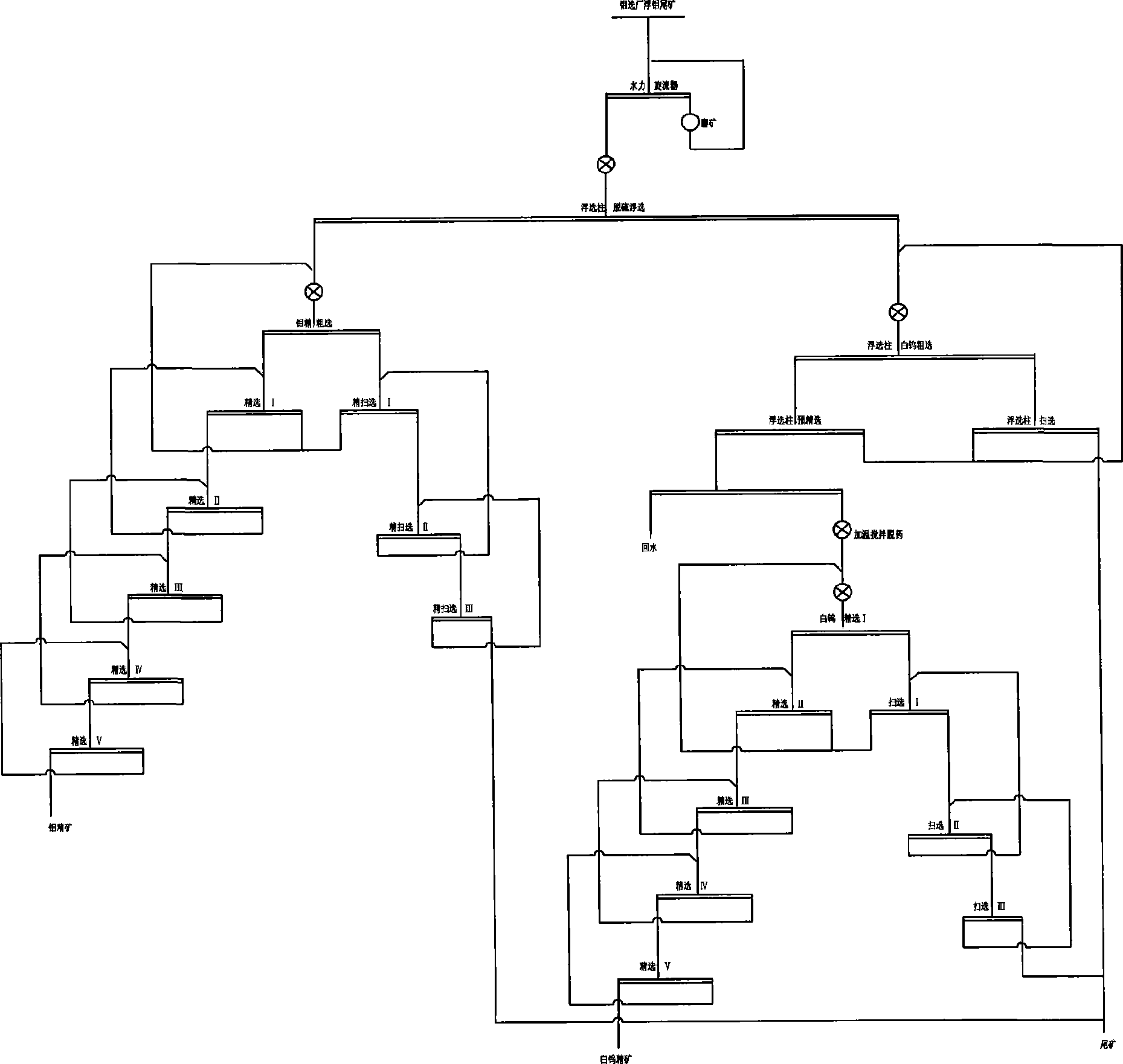

[0033] The specific process is shown in Figures 1 and 2. First, it enters the desulfurization and separation system for molybdenum: the molybdenum tailings of the molybdenum separation plant flow to the pump pool 1 by itself, and the slurry is sent to the hydrocyclone 3 through the slurry pump 2, and the hydrocyclone 3 The grit flows to the ball mill 4. The ball mill 4, the slurry pump 2 and the cyclone 3 form a closed-circuit grinding cycle, so that the grinding particle size can meet the qualified requirements. The ore slurry with qualified particle size flows to the mixing tank 5 through the overflow of the hydrocyclone 3, and enters the desulfurization flotation column 6 for desulfurization flotation after stirring. The concentrate of the desulfurization flotation column 6 flows into the mixing tank 7, and enters the flotation machine 8 after being stirred, and the molybdenum rough concentration, five times of molybdenum concentration, and three times of molybdenum fine sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com