High temperature halogen-free flame retardant polypropylene/ethylene propylene terpolymer cable material and preparation method thereof

A technology of EPDM rubber and flame-retardant polypropylene, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low heat resistance temperature and high hardness, and achieve low hardness, good flexibility, and extended use range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

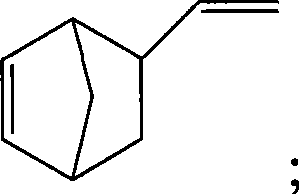

Image

Examples

Embodiment 1~5

[0066] Preparation method: According to the formula in Table 1, polypropylene, EPDM rubber, ammonium polyphosphate, silicone, cross-linking agent and other additives were mixed in a plastic mixing pot for 5 minutes, and the mixture was extruded from the twin-screw The main feeding port of the machine is added, the feeding rate is 50 kg / hour, and the rubber oil is added from the middle area of the twin-screw to adjust the hardness of the product to the set value. The diameter of the twin-screw extruder is 65 mm, the length-to-diameter ratio is 48, the temperature control range is 140° C. to 200° C., and the screw speed is controlled at 290 rpm. The properties of the products obtained are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com