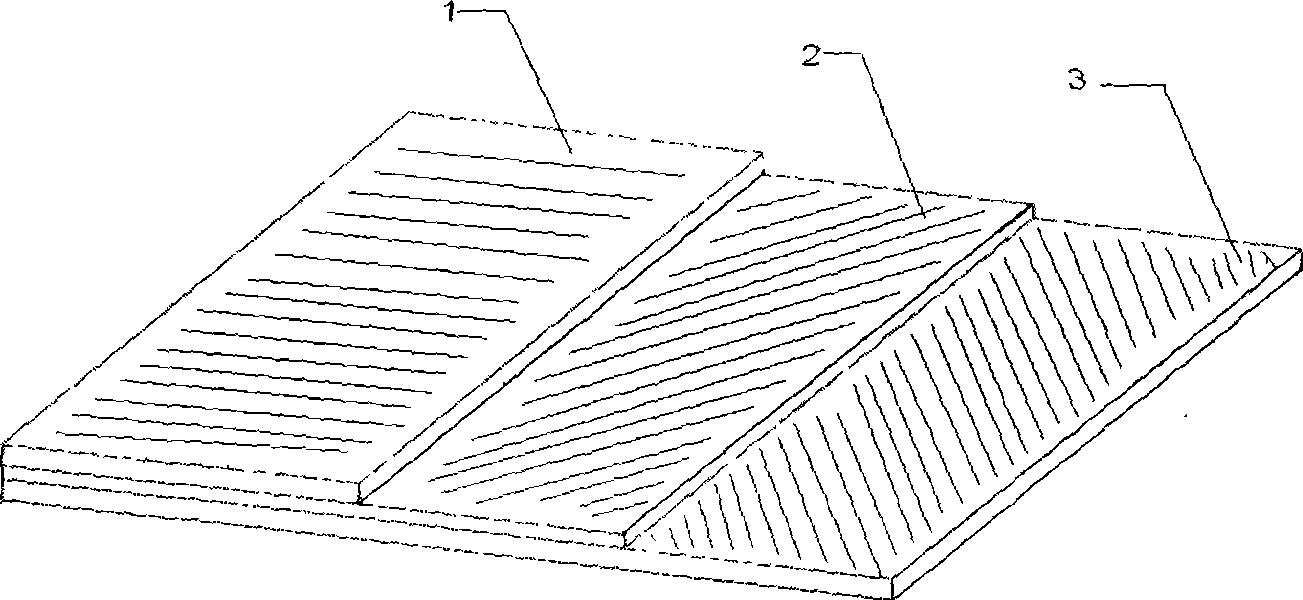

Method for preparing leached fibre felt by electrostatic dry method

A fiber mat and electrostatic technology, which is used in the field of thermoplastic or thermosetting fiber mat preparation, can solve the problems of inability to bond, difficult to mix resin powder uniformly, and difficulty in industrialized production, and achieves rapid impregnation, low energy consumption, and low investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

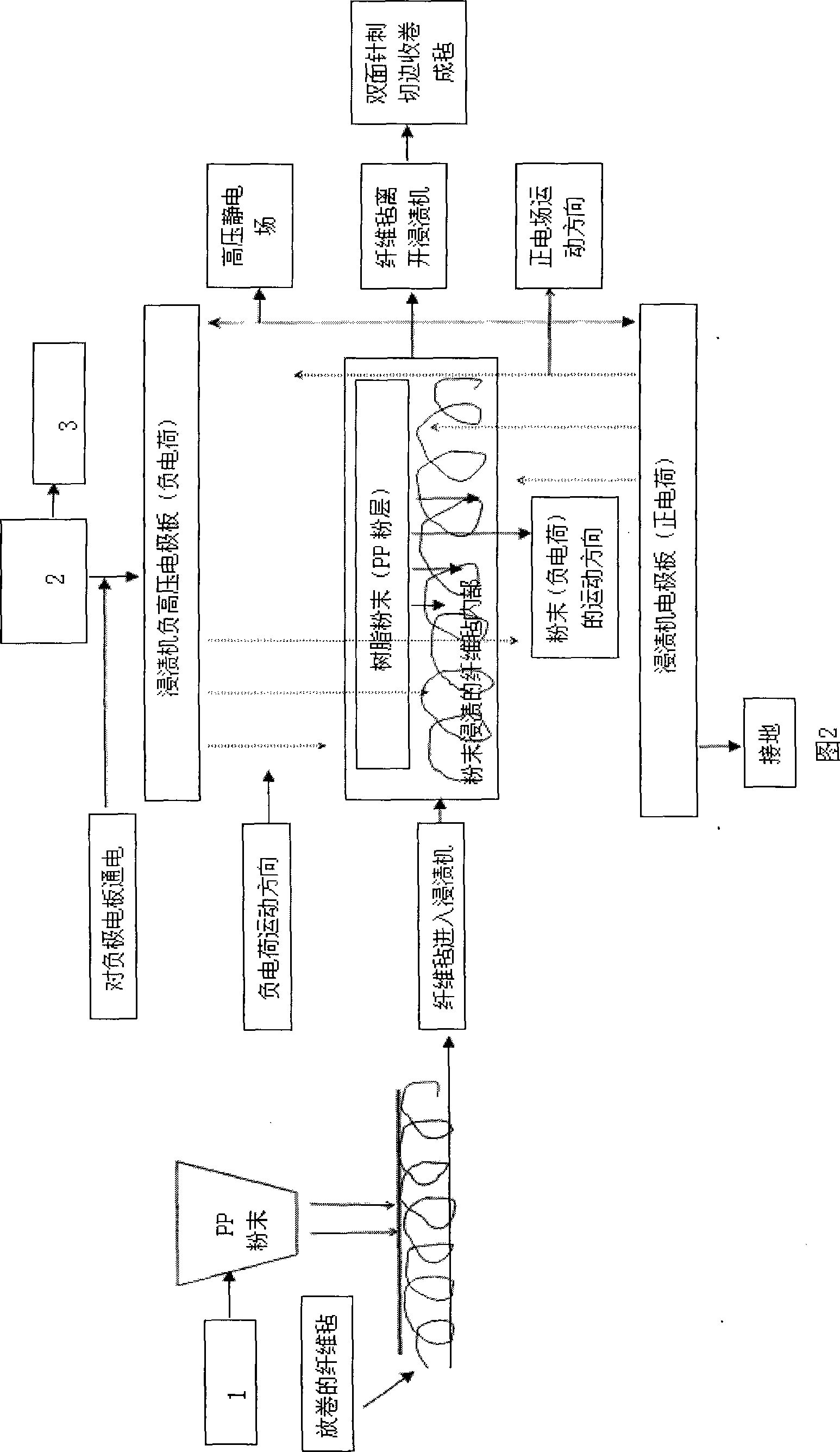

Method used

Image

Examples

Embodiment 1

[0028] (1) Material preparation: 50kg of modified non-alkali glass fiber roving (diameter: 13μm, 1200tex glass fiber surface has been processed by the manufacturer according to requirements), 50kg of modified polypropylene fiber filaments (diameter: 20μm), 25kg of polypropylene powder (particle size 10μm.), polypropylene non-woven fabric 50m2 roll (25g / m 2 );

[0029] (2) Place the modified glass fiber roving and the modified polypropylene fiber evenly on the creel, and send them to the molding section of the chopped strand mat production line at the same time according to the ratio of the above-mentioned materials for chopping, blending, and chopping. The length is 60-90mm, and then settle and lay the net to form a fluffy and evenly mixed glass fiber blank mat;

[0030] (3) Import the polypropylene powder into the powder spreading device 1 and press 250g / m on the surface of the glass fiber blank felt 2 Sprinkle powder to spread a uniform layer of resin powder on the surface...

Embodiment 2

[0040] (1) Material preparation: 50kg hemp fiber (diameter: 15μm), 50kg modified polypropylene fiber (diameter: 30μm), 25kg polypropylene powder (particle size 10μm.), polypropylene non-woven fabric 50m 2 rolls (25g / m 2 );

[0041] (2) Place the hemp fiber and the modified polypropylene fiber evenly on the creel, and send them into the molding section of the chopped strand felt production unit at the same time according to the ratio of the above-mentioned stock preparations, and chop and blend them. The chopped length is 60-90mm, Then settle and lay the net to form a fluffy and evenly mixed hemp fiber blank felt;

[0042] (3) Import the polypropylene powder into the powder spreading device 1 and press 250g / m on the surface of the hemp fiber blank felt 2 Sprinkle powder to spread a uniform layer of resin powder on the surface of the blank felt;

[0043](4) Start the high-voltage DC generator 3 and pass through the electrostatic generator 2 to energize the negative electrode p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Chopped length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com