Reflection layer material for electrochromic lens and device thereof

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of increased driving voltage, decreased performance, accelerated aging of devices, etc., to achieve lower driving voltage, excellent performance, lower The effect of the contact barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

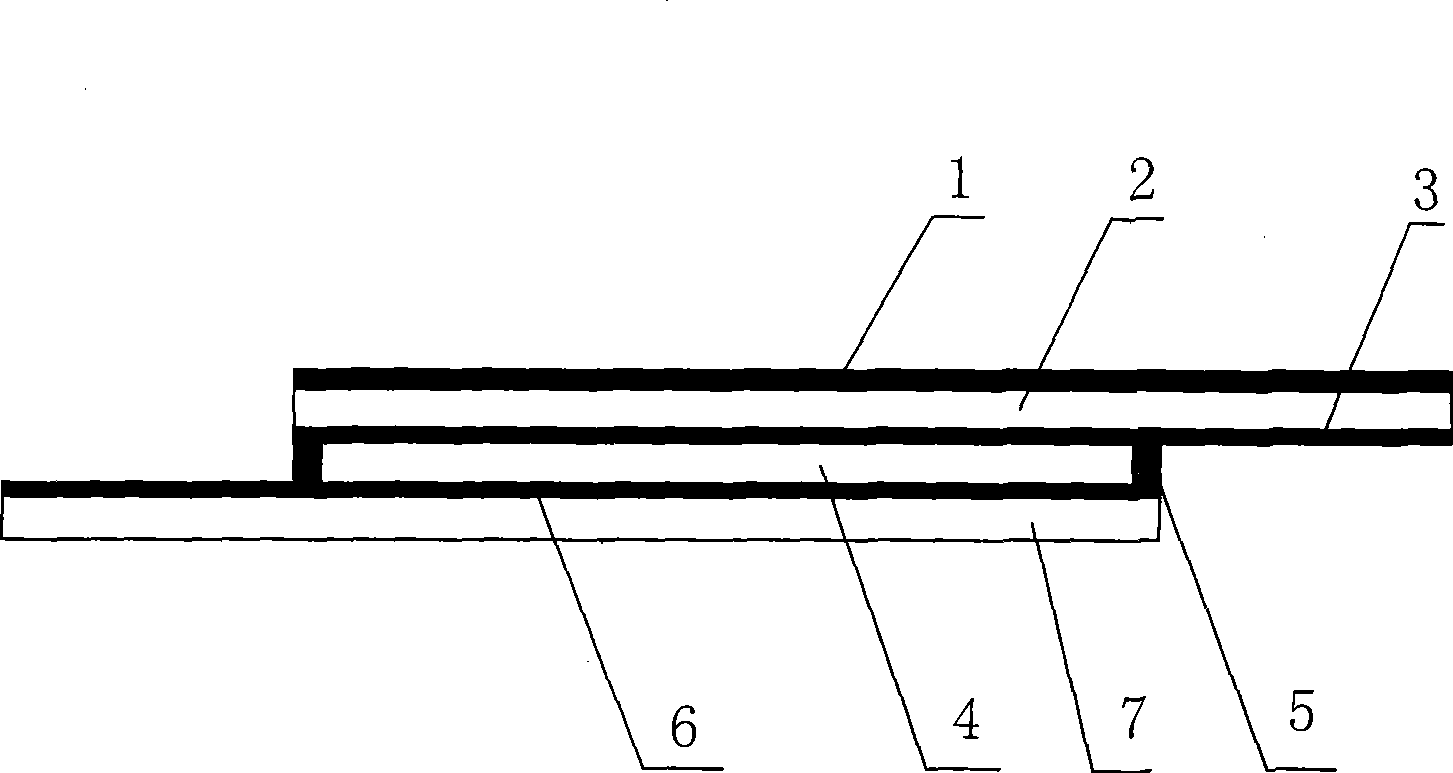

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

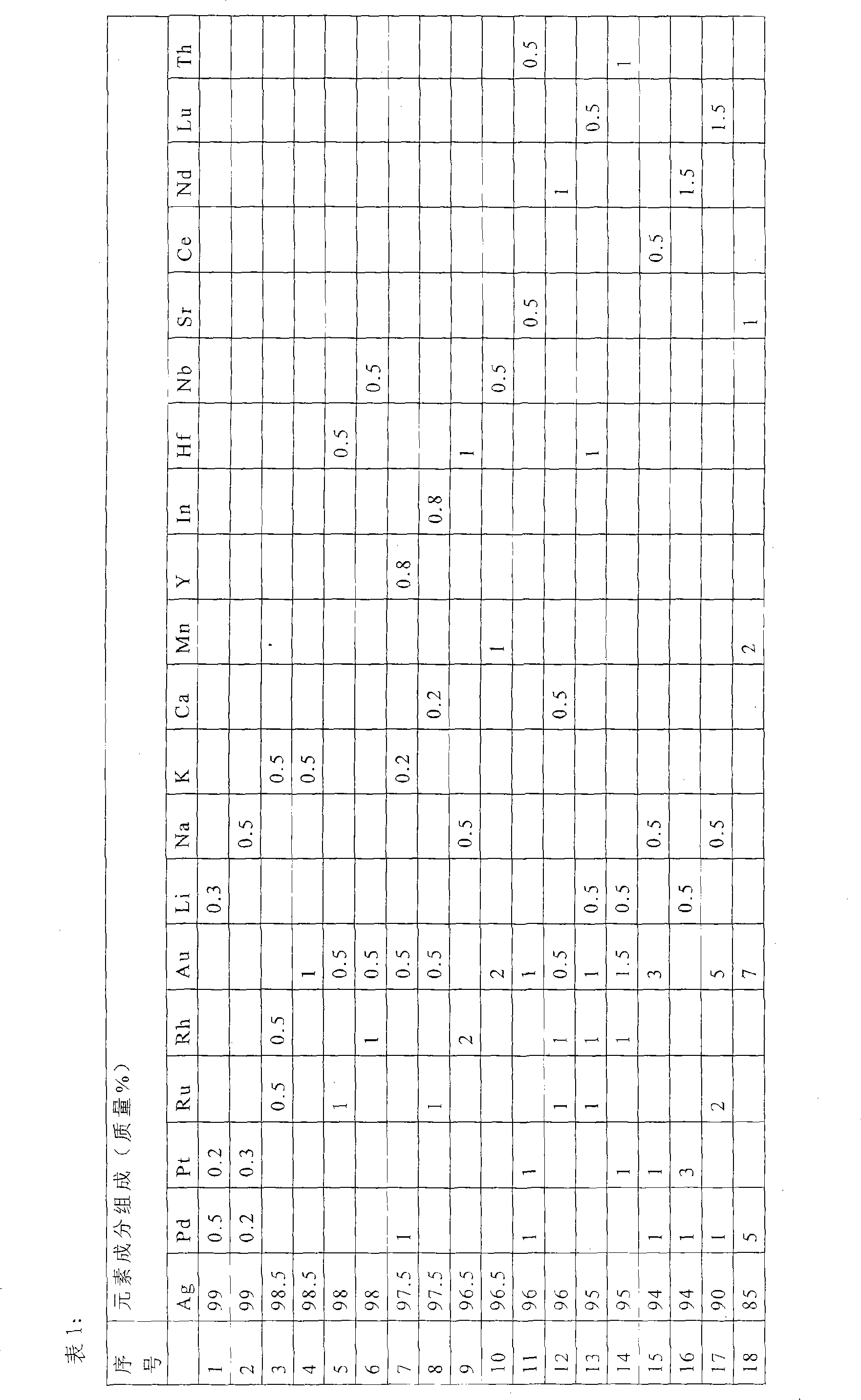

[0020] Using high-purity silver above 99.99% (the same as below by weight), Pd, Pt, Ru, Rh, Au, Li, Na, K, Ca, Mn, Y, In, Hf, Nb, Sr, Ce with a purity above 99.9% , Nd, Lu, Th, etc. one or more to prepare silver alloy, and then use this alloy to plate a conductive reflective film. The detailed data is as follows in Table 1:

[0021]

[0022] The reflectivity, work function, driving voltage, corrosion resistance of the above-mentioned coating, the reflectivity after the electrochromic device is made, and the durability data of the reflective layer are as follows in Table 2:

[0023] Table 2

[0024] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com