Alginate jelly and production method thereof

A technology of alginate and sodium alginate, which is applied in the food field, can solve the problems of poor water retention performance of jelly, fast molding time, uneven gel, etc., and achieves the effects of long water retention rate, increased water retention, and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

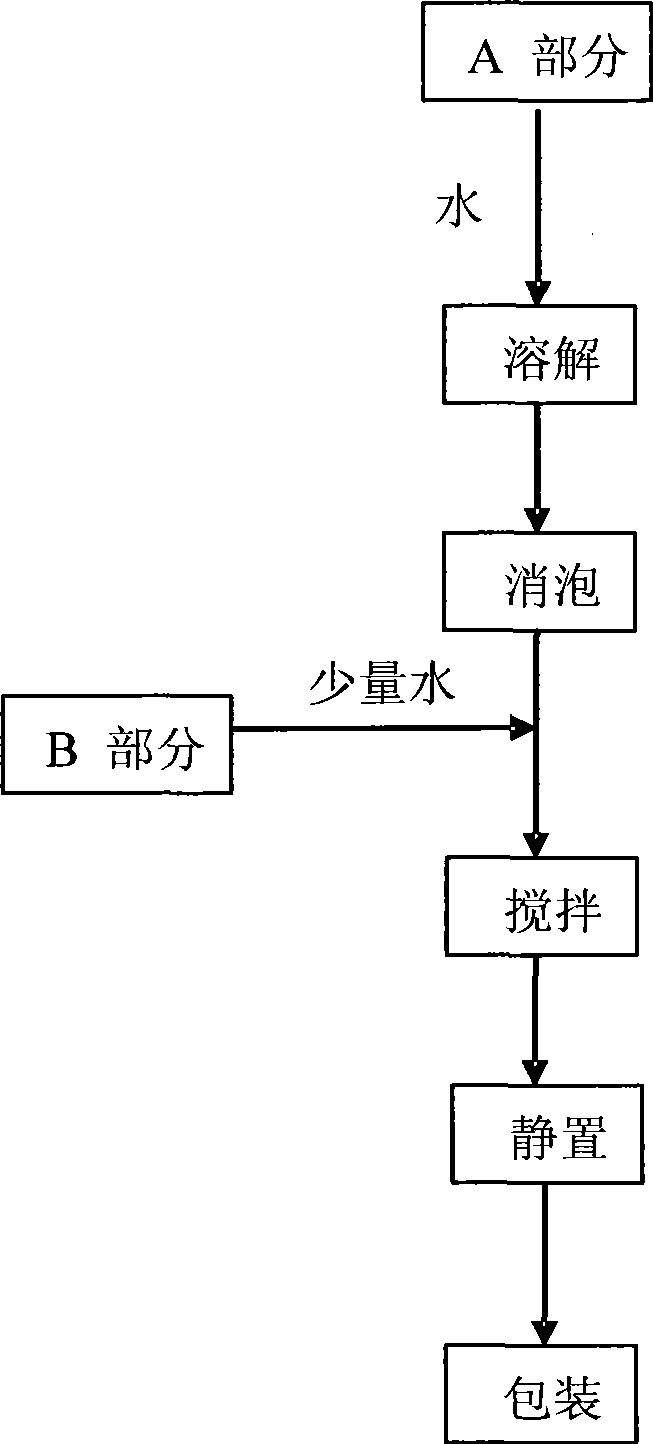

Method used

Image

Examples

example 1

[0027] Jelly Ingredients Recipe:

[0028] Component A: Sodium Alginate 6g

[0029] Guar gum 0.5g

[0030] Component B: calcium sulfate dihydrate 2.7g

[0031] Sodium hexametaphosphate 0.8g

[0032] Mix components A and B evenly, mix component A with 650g hot water and stir evenly, dilute component B with a small amount of water and stir well, stir solution A quickly in the same direction, add solution B, stir well, pour into the Put it in the mold and let it stand for about 2 hours to become jelly.

example 2

[0034] Jelly Ingredients Recipe:

[0035] Component A: Sodium Alginate 17.1g

[0036] Guar Gum 2.1g

[0037] Sodium carboxymethylcellulose 0.9g

[0038] Component B: calcium sulfate dihydrate 8.4g

[0039] Sodium tripolyphosphate 1.2g

[0040] Mix components A and B evenly, mix component A with 1750g hot water and stir evenly, dilute component B with a small amount of water and stir well, quickly stir solution A along the same direction, add solution B, stir well, pour into the Put it in the mold and let it stand for about 125 minutes to become jelly.

example 3

[0042] Jelly Ingredients Recipe:

[0043] A component: sodium alginate 1.3kg

[0044] Guar gum 0.08kg

[0045] Sodium carboxymethyl cellulose 0.04kg

[0046] Konjac Powder 0.04kg

[0047] Component B: calcium sulfate hemihydrate 0.4kg

[0048] Sodium hexametaphosphate 0.1kg

[0049] Sodium tripolyphosphate 0.04kg

[0050] Mix components A and B evenly, mix component A with 150kg hot water, add a certain amount of carrot juice to the hot water, stir evenly, let it stand for defoaming, dilute component B with a small amount of water and stir well, use a pump Mix A and B solutions, stir evenly, pour into molds, and let it stand for about 100 minutes to become carrot-flavored jelly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com