Assembling and welding technique of ship water-jet propulsion flow-passage grid

A water-jet propulsion and grille technology, which is applied in shipbuilding, manufacturing tools, welding equipment, etc., can solve the problems that the movable model or sample box cannot be made according to the requirements, the structure is strong, and the shape of the hull is complicated, so as to avoid cracks or The effect of breaking the grid strips, ensuring the quality and strength, and meeting the technical requirements and precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

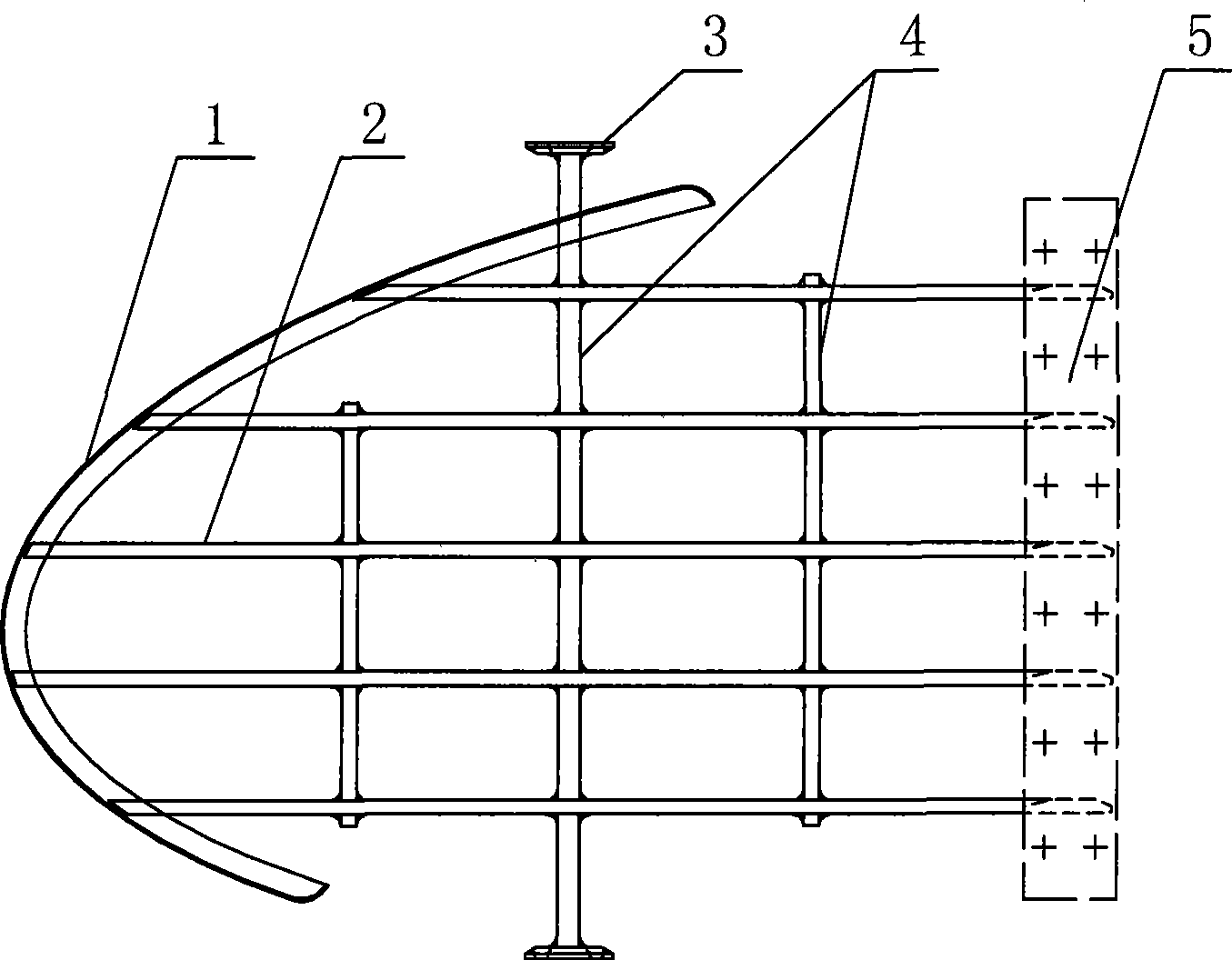

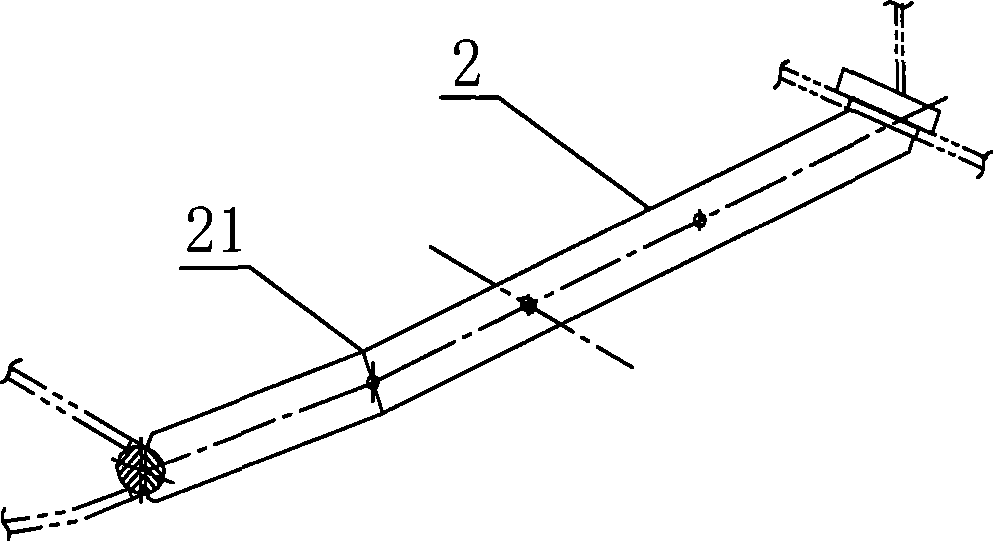

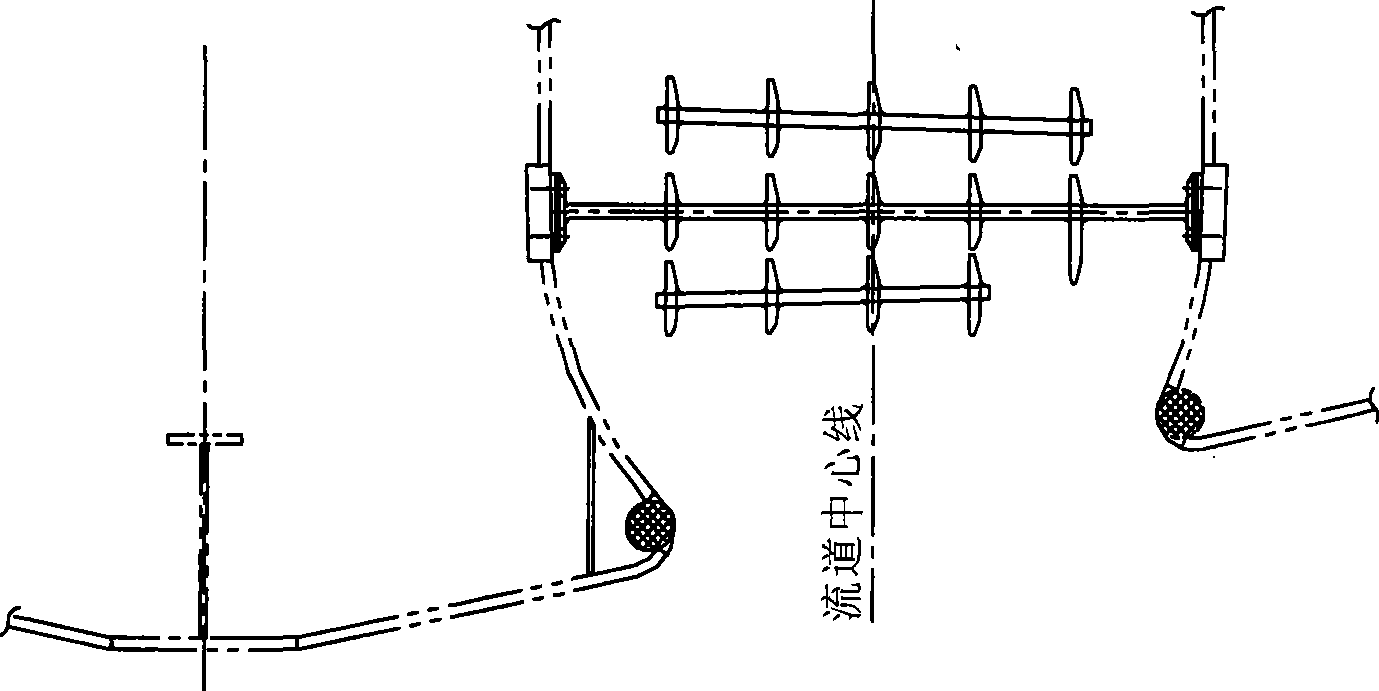

[0031] Such as figure 1 As shown, the stainless steel runner grille of the water jet propulsion channel of the ship is composed of the front grille frame 1, the rear grille frame 5, the grille bar 2, the crosspiece 4 and the crosspiece seat 3, the grille bar 2 and the crosspiece 4. Vertical and horizontal intersect to form a grid shape, the two ends of the grid bar 2 are connected with the front grid frame 1 and the rear grid frame 5 respectively, and the crosspiece seat 3 is connected with the two ends of a middle crosspiece. Wherein the front grille frame 1, the rear grille frame 5 and the transom seat 3 need to be fixed in the hull flow channel, especially because the front grille frame 1 is a long curve, it should be well matched with the hull flow channel, and To reduce internal stress, the assembly of components should be carried out on-site in the flow channel. The specific process is as follows:

[0032] (1) Processing and manufacturing of grille components

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com