Depolymerization and recovery method of high temperature resistant nylon poly-para-phenylene diformyl hexane diamine

A technology of polyhexamethylene terephthalamide and polyhexamethylene terephthalamide, which is applied in the field of high temperature resistant nylon polyhexamethylene terephthalamide depolymerization, and can solve the problem of no literature on PA6T recycling. or patent issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

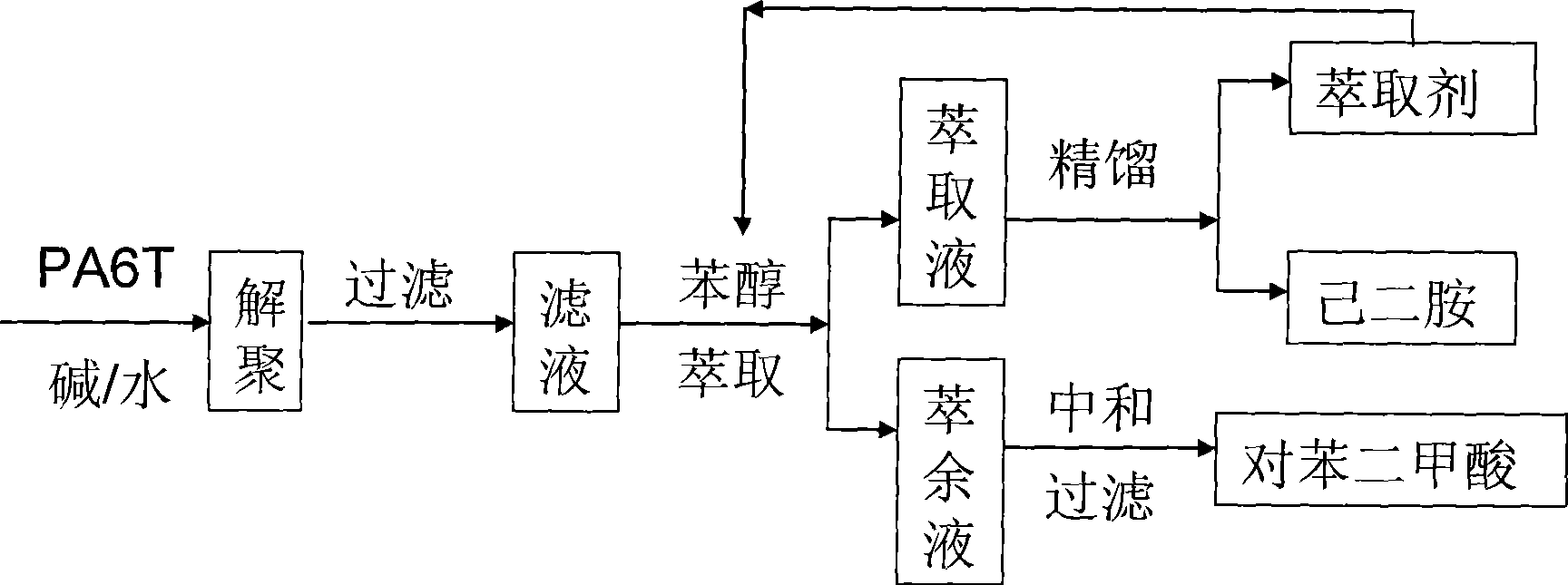

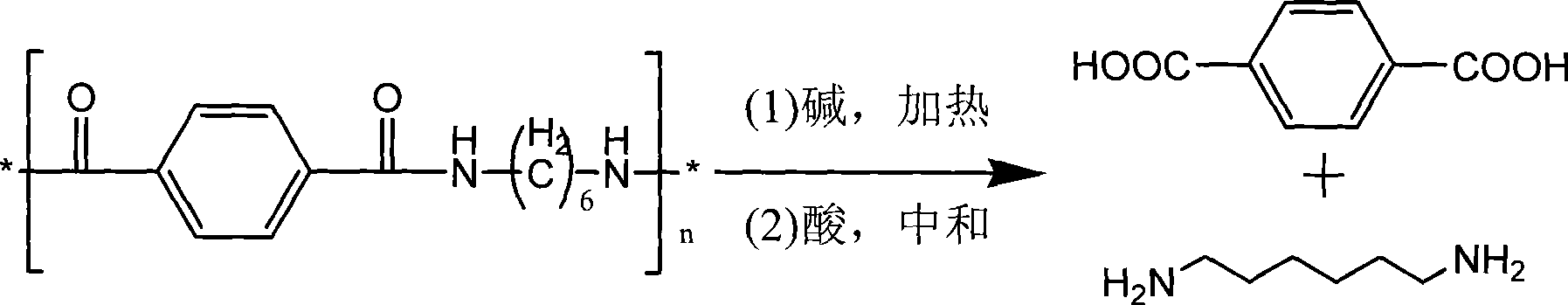

[0018] Add 500Kg solid sodium hydroxide and 1000Kg water into the reaction kettle, stir and dissolve, then add the crushed waste nylon PA6T. React under the condition of 0.6MPa for 5 to 8 hours to complete the reaction and obtain an alkaline hydrolyzate; then filter the alkaline hydrolyzate through a coarse filter to remove solid residues, add benzene / n-butanol mixed extractant after cooling, and the extractant The molar ratio is 2:1, the crude hexamethylenediamine is extracted, the extract is subjected to fractional distillation in the rectification tower, and the distilled organic solvent is compounded with a fresh solvent and continues to be used as an extractant in the next production cycle; After extracting solvent with boiling point, carry out rectification under reduced pressure, control the collection temperature of hexamethylenediamine fraction to be lower than 170°C, and obtain hexamethylenediamine with a purity greater than 99.1%; the aforementioned raffinate is sodi...

Embodiment 2

[0020] Add 250Kg solid sodium hydroxide and 1000Kg water into the reaction kettle, stir and dissolve, then add the crushed waste nylon PA6T, the molar ratio of sodium hydroxide to PA6T is 2.5:1, stir, and keep the temperature at 70-90°C and the pressure at 0.1~ React under the condition of 0.6MPa for 5 to 8 hours to complete the reaction and obtain an alkaline hydrolyzate; then filter the alkaline hydrolyzate through a coarse filter to remove solid residues, add benzene / n-butanol mixed extractant after cooling, and the extractant The molar ratio is 1:1, the crude hexamethylenediamine is extracted, and the extract is subjected to fractional distillation in the rectification tower, and the distilled organic solvent is compounded with fresh solvent and continues to be used as the extraction agent in the next production cycle; Carry out vacuum rectification after the extraction solvent with boiling point, control the collection temperature of hexamethylenediamine fraction to be low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com