Cyan and yellow balancing bamboo floor

A bamboo flooring and flooring technology, which is applied to floors, buildings, building structures, etc., can solve the problems of complicated manufacturing process, high cost, and bent bamboo floor tiles, and achieve good tensile and compressive properties, resource saving, and sound insulation good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

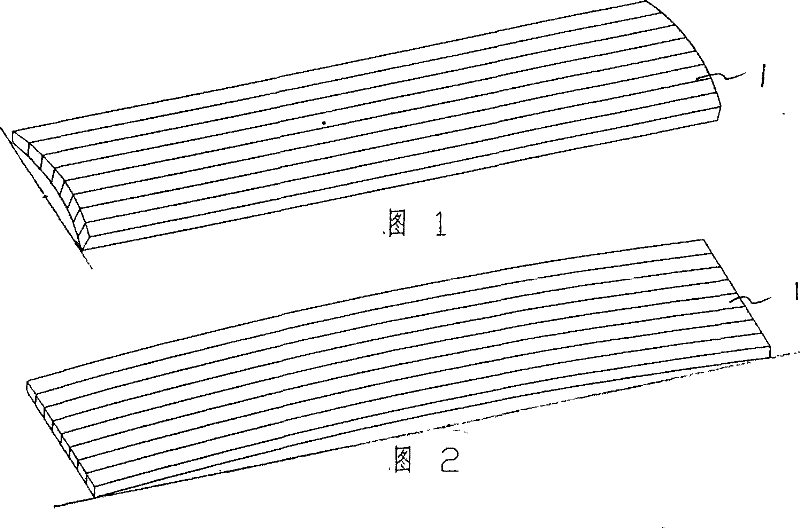

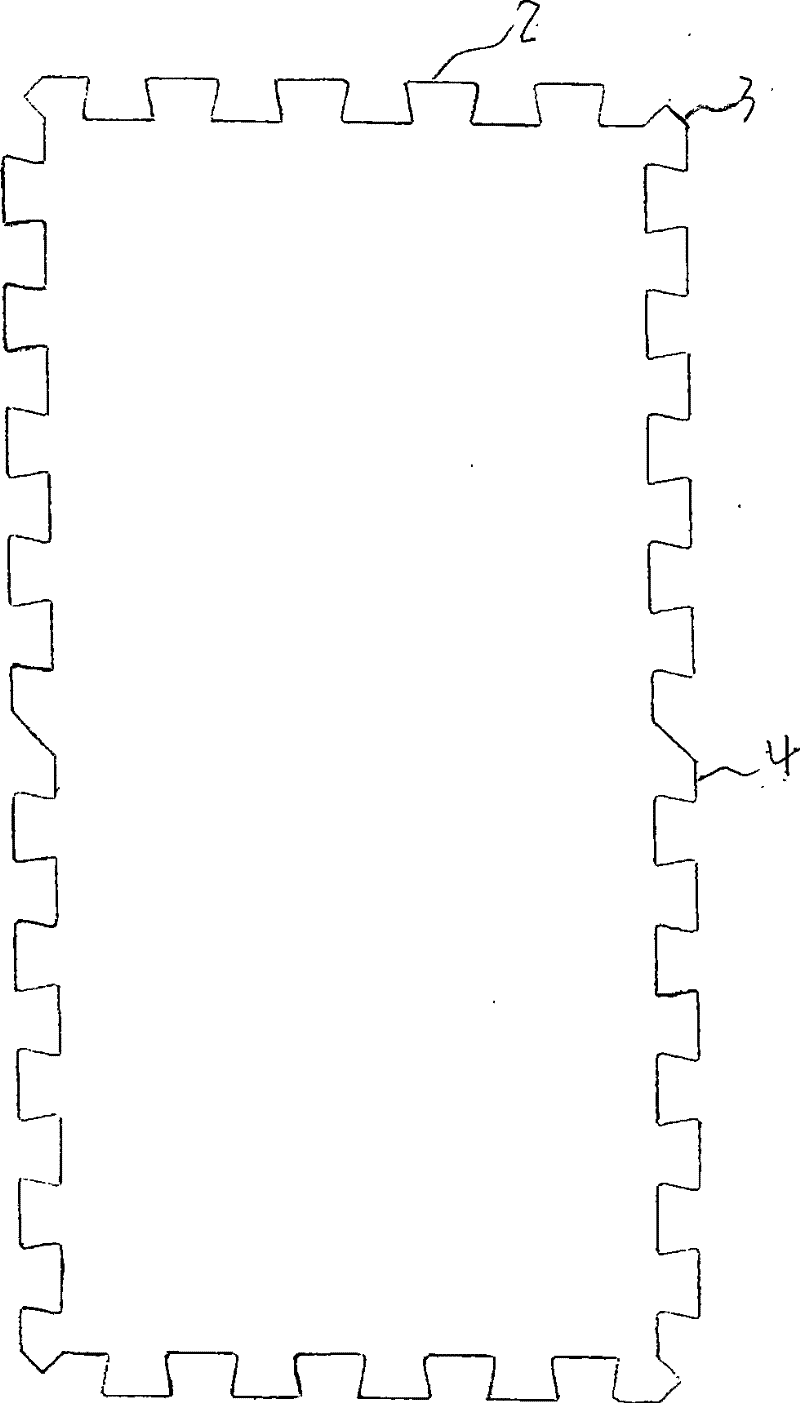

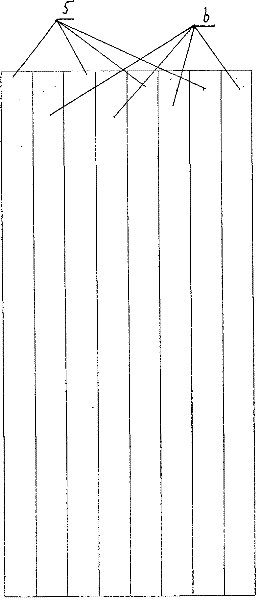

[0017] Embodiment 1, with reference to Figure 4 , Natural bamboo is cut into strips, and the strips are selected after finishing. The dark bamboo strips and the light-colored bamboo strips are each in a group. After the positive and negative cross stitching, enter the press, take out the bamboo veneer through conventional high-temperature pressing for 2-3 minutes, and then undergo conventional constant temperature, normal temperature health care and shaping, and then mechanically process to obtain the main body of the floor 1. The surface of the main body of the floor is coated with UV paint and punched. The molded EVA elastic floor carrier 7 is glued into a blue-yellow balanced bamboo floor assembly, and its shape and structure refer to Figure 5 , 6 . Resilient floor carrier 7 is rectangular, with reference to image 3 , the four sides are provided with matching tail tenon 2, angle tenon 3 and oblique tenon 4. Tail tenon 2 is the active tenon combined between the floors...

Embodiment 2

[0018] Embodiment 2, the surface of the main body of the floor is coated with PU paint and glued with the die-cut PEA elastic floor carrier 7 to form a blue-yellow balanced bamboo floor assembly. The elastic floor carrier 7 is a square, and the effective surface of the floor main body is 1 mm larger than the effective surface of the elastic floor carrier. All the other are identical with embodiment 1.

Embodiment 3

[0019] Embodiment 3, after coating the surface of the main body of the floor with an aluminum oxide film and gluing the die-cut non-woven felt elastic floor carrier 7 into a blue-yellow balanced bamboo floor assembly. The effective surface of the main body of the floor is 1.1 mm larger than the effective surface of the elastic floor carrier. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com