Recovery plant for waste water heat energy

A heat recovery and equipment technology, applied in heat exchange equipment, lighting and heating equipment, damage protection, etc., can solve problems such as heat exchanger pollution, and achieve the effects of saving water resources, reducing production costs, and saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

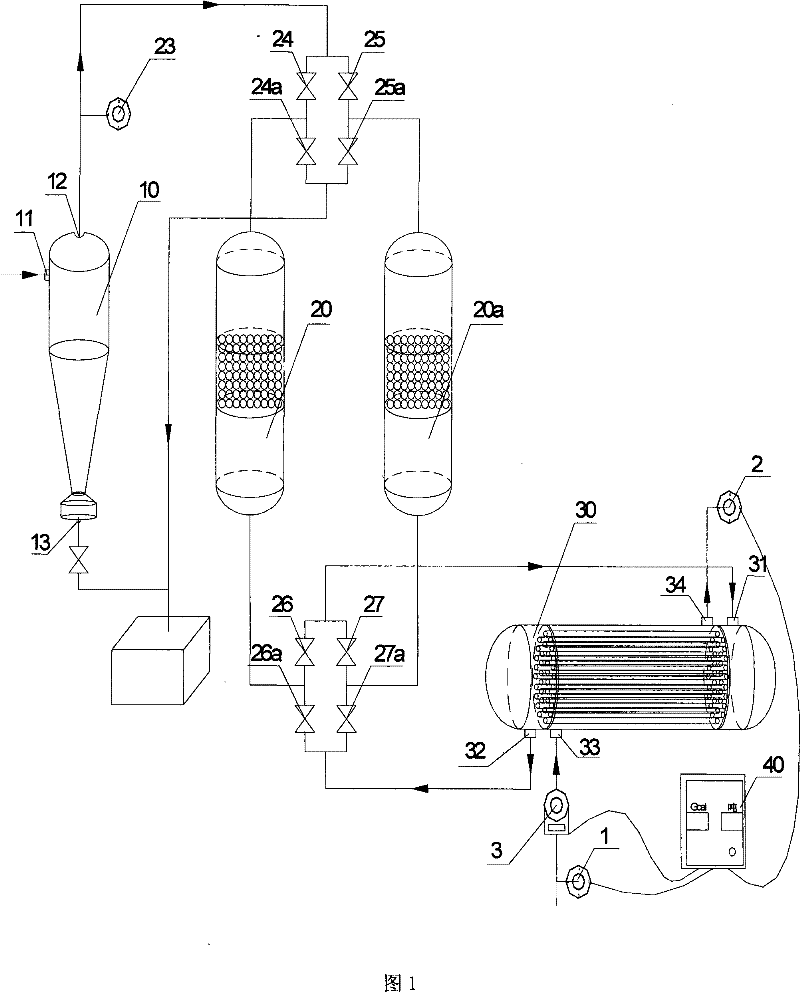

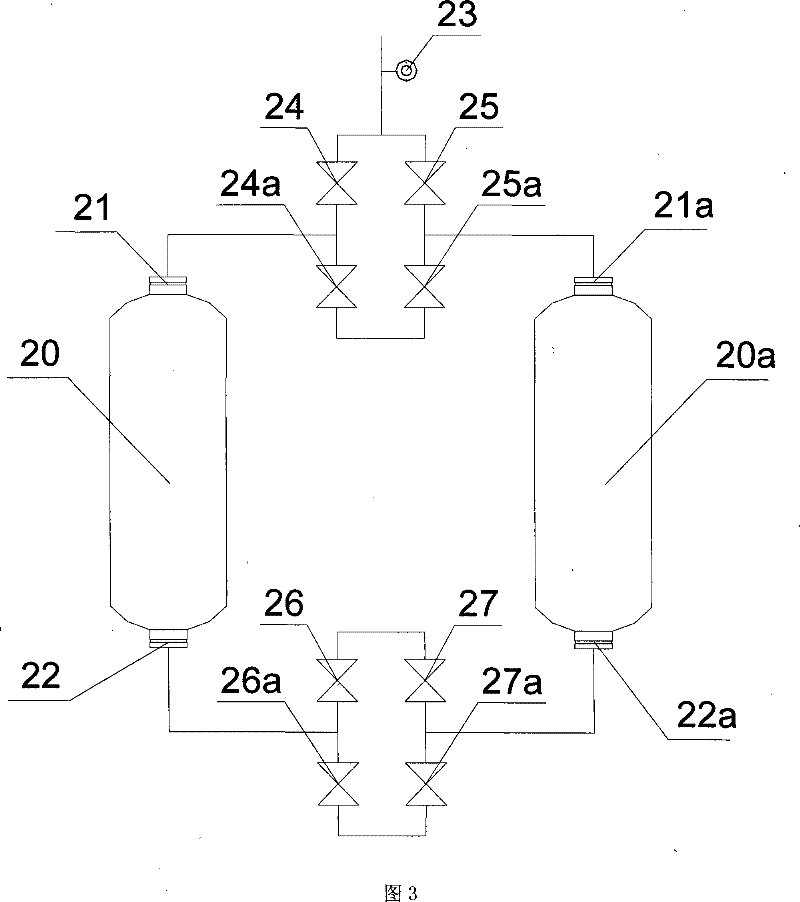

[0017] Such as figure 1 As shown, the waste water heat energy recovery equipment includes a waste water centrifugal filter device (10), the granular filter device (20) and (20a) that enters into automatic switching from the outlet of the centrifugal filter device, and the waste water and hot water that enters from the outlet of the particle filter device and The heat exchanging unit (30) of the cold water finally includes a heat accumulation device (40) for confirming fuel savings.

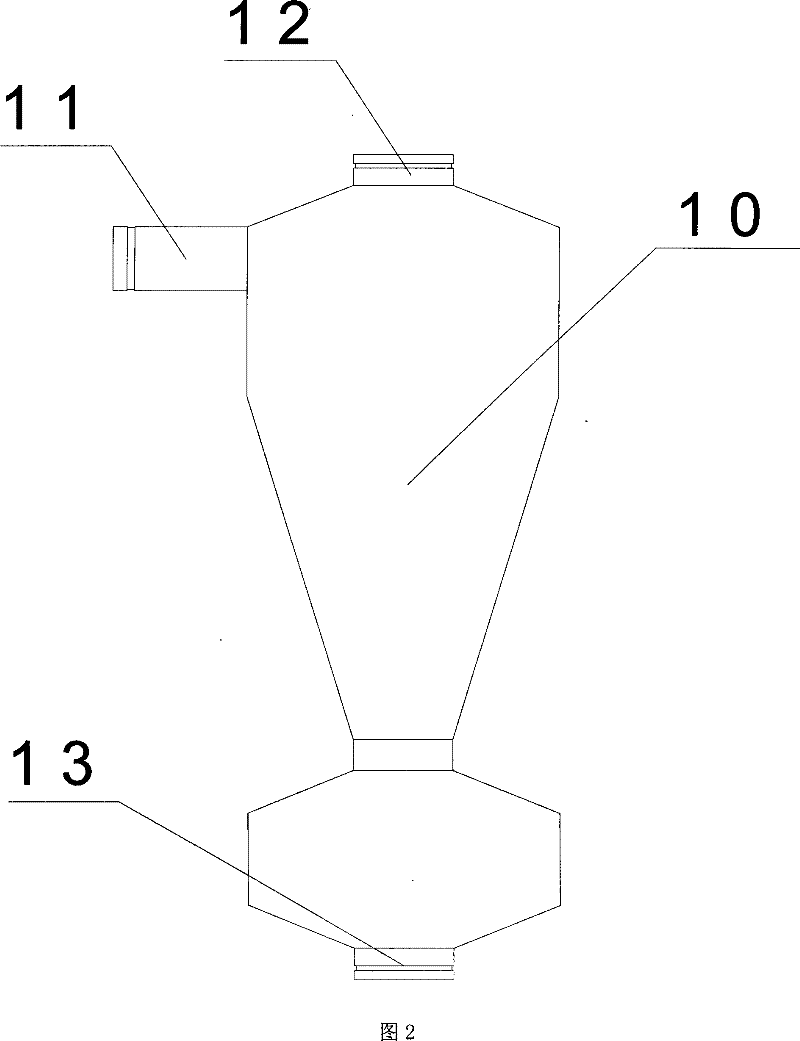

[0018] figure 1 The middle arrow points to the process flow direction of the entire equipment. The medium and high-temperature wastewater discharged from factories and buildings is firstly collected centrally and then transported by the sewage lift pump to the figure 2 The water inlet (11) of the centrifugal filter separation device (10) shown, through the mechanical centrifugal force separation technology, the particulate matter in the wastewater with a specific gravity larger than water is sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com