Functional carbon material synthesized with one-step reaction and method for producing the same

A technology of carbon materials and functionalization, which is applied in the field of one-step reaction synthesis of functionalized carbon materials and its preparation, can solve problems such as uneconomical, troublesome treatment of three wastes, and serious corrosion of equipment, and achieve simple and easy operation, improved dispersion, and Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

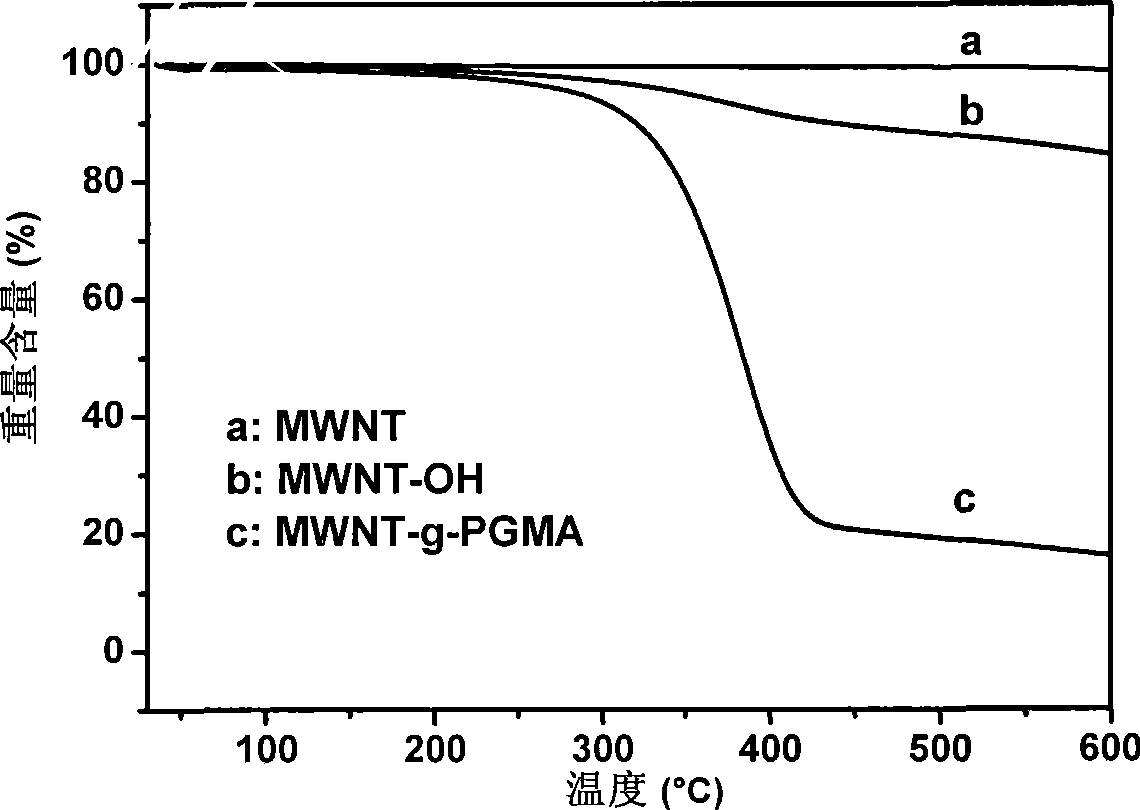

[0037] The multi-walled carbon nanotubes prepared by the catalytic pyrolysis method are used as the initial raw materials and reacted with azido compounds such as 2-azidoethanol to obtain hydroxyl-containing carbon nanotubes. In a 250mL single-neck round bottom flask equipped with a magnetic stirring rotor, add 1g of carbon nanotubes and 80mL of N-methylpyrrolidone. After ultrasonic treatment with 40kHz for 2 hours, add 20g of 2-azidoethanol to the reaction flask and heat Reaction for 18 hours under stirring at 160°C, after suction filtration or centrifugal separation, 60°C vacuum drying for 24 hours to obtain functionalized carbon nanotubes containing hydroxyl groups. Thermal weight loss analysis shows that the mass content of the connected organic components is 11% (more The thermal weight loss diagram of wall carbon nanotube raw materials is shown in figure 1 a. The thermal weight loss diagram of functionalized carbon nanotubes is shown in figure 1 b. See the transmission ele...

Embodiment 2

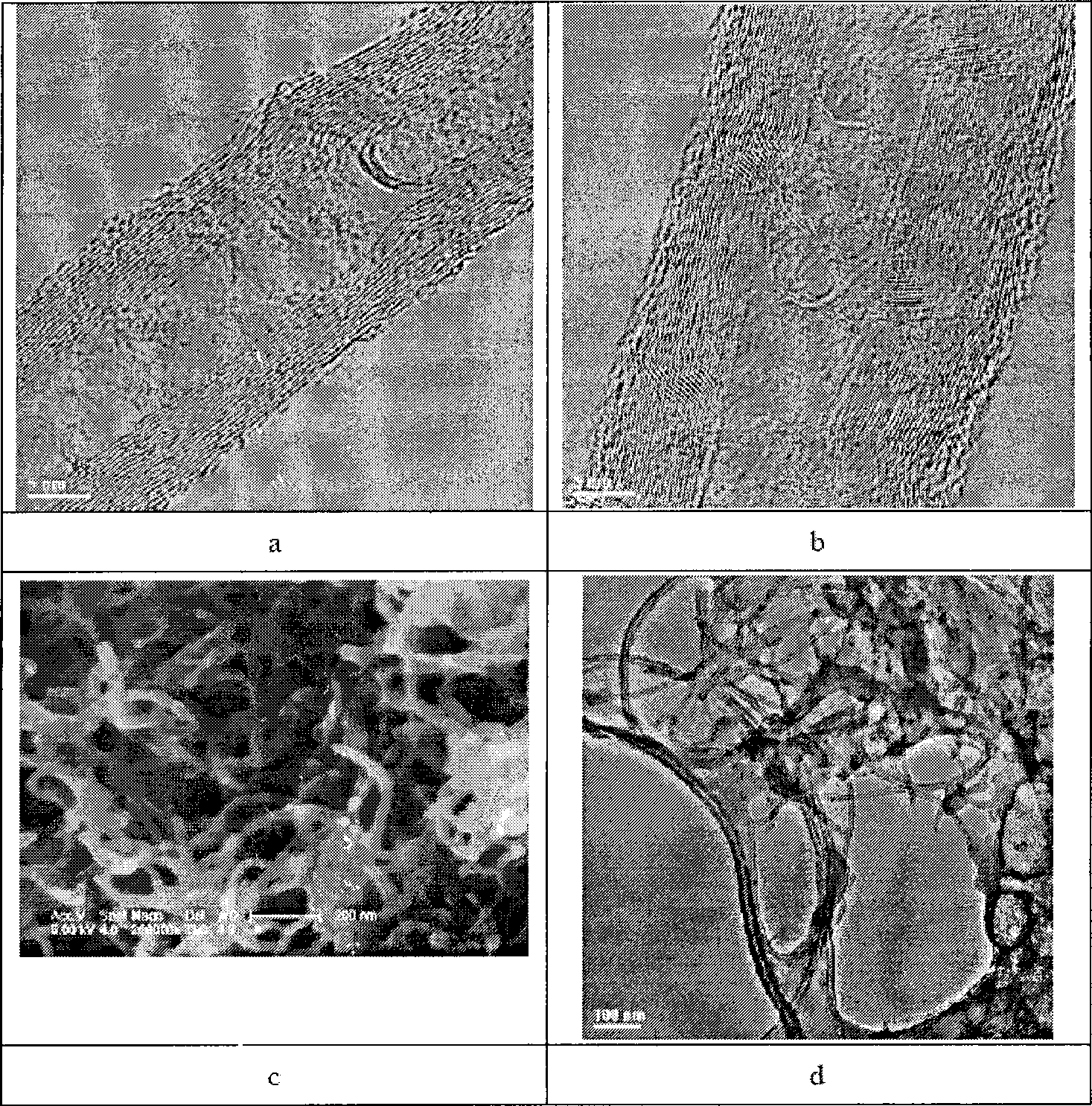

[0039] The hydroxyl-containing carbon nanotubes obtained in Example 1 were used as initiators to initiate the cationic ring-opening polymerization reaction of glycidyl methacrylate, reacted at 110°C for 15 hours, centrifuged, and dried to obtain polymer-grafted carbon For nanotubes, the grafting amount of polymer reaches 80%, indicating that the density of hydroxyl groups attached to the surface of the functionalized carbon nanotubes obtained in Example 1 is very high (the thermal weight loss diagram of polymer-grafted carbon nanotubes is shown in the figure figure 1 c, see the scanning electron microscope photo image 3 c, see the infrared spectrum Figure 5 b).

Embodiment 3

[0041] Using the same reaction steps as in Example 1, the carbon nanofibers were used as raw materials and treated with 10kHz ultrasonic for 100h. After the reaction, functionalized carbon nanofibers containing hydroxyl groups were obtained after separation and drying. Thermal weight loss analysis showed that the mass content of the connected organic components was 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com