Polyethylene imine modified carbon nano-tube, its complexes, production method and uses thereof

A polyethyleneimine, carbon nanotube technology, applied in the field of carbon nanotubes, can solve the problem of not being able to confirm the influence of PEI molecular weight, etc., and achieve the effects of low cytotoxicity and high transfection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: Oxidation cutting and polishing of MWCNTs

[0028] Pristine MWCNTs (purchased from Nanometer Port, Shenzhen) were soaked in 6M HCl for seven days, washed sequentially with dilute NaOH solution, deionized water, and dried to obtain pure MWCNTs with demetallized catalysts. Put 100mg of pure MWCNTs into 80ml H at 3:1 2 SO 4 / HNO 3 In the mixed solution, sonicate for 24 hours in a water bath at 40-50°C. Centrifuge (7000rpm, 5min), dilute the precipitate with deionized water, filter through a 0.22μm polytetrafluoroethylene membrane, wash fully with deionized water, put into 4:1 concentrated 50ml H 2 SO 4 / 30%H 2 o 2 The mixed solution was stirred at 70°C for 30 min. to obtain oxidized cut and polished MWCNTs.

example 2

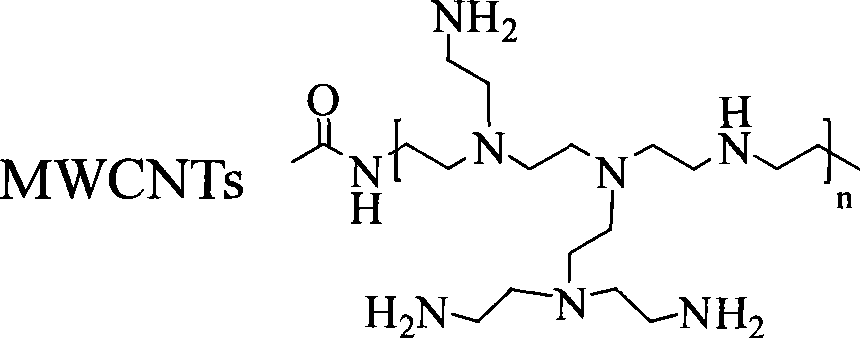

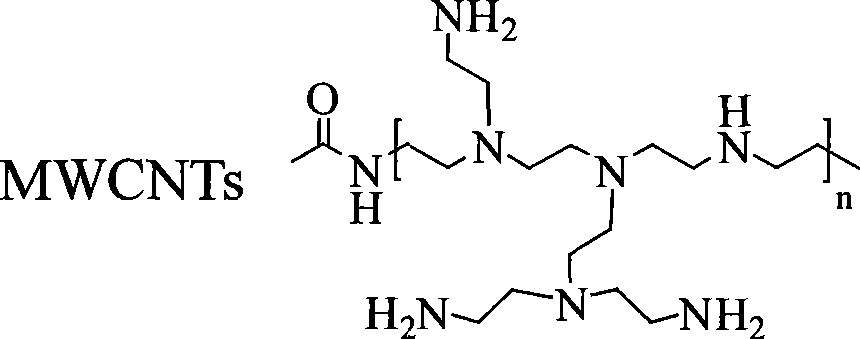

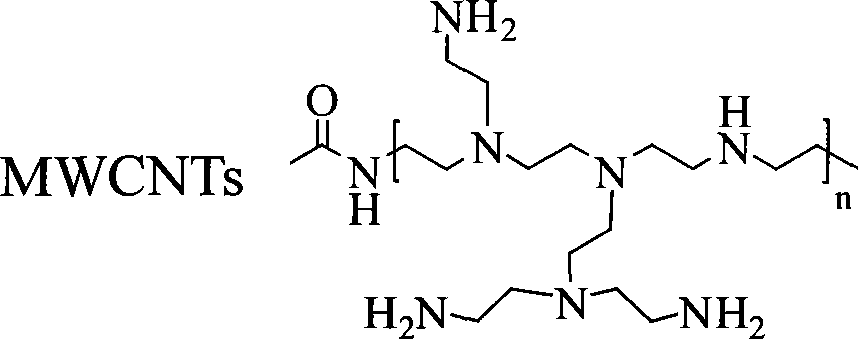

[0029] Example 2: PEI grafted with MWCNTs

[0030] Oxidatively cleaved MWCNTs (20 mg), ethyl-3-(dimethylaminopropyl)carbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) were placed in 50 ml sodium phosphate buffer solution (PBS) , after stirring for 24 h under the protection of nitrogen, polyethyleneimine (Mn=22-600 kDa) was added, and the stirring was continued for 24 h. The reaction mixture was added to a 10-fold excess of absolute ethanol, filtered through a 0.22 μm polytetrafluoroethylene membrane, rinsed with absolute ethanol and deionized water in turn, and the obtained PEI-g-MWCNTs had good dispersibility in deionized water , The suspension is stable for 1 month. While the cut and polished MWCNTs precipitated after 2h.

example 3

[0031] Example 3: Content of polyethyleneimine in PEI-g-MWCNTs

[0032] The weight of supramolecular PEI grafted onto the surface of MWCNTs was obtained by thermal analysis (TGA) in nitrogen atmosphere. The MWCNTs used in the present invention are stable at 600°C, PEI is completely decomposed at 500°C, the weight loss of MWCNTs is about 2.5%, while that of PEI-g-MWCNTs is 10.5%, and the weight of grafted PEI is about 8%. The PEI-grafted MWCNTs were suspended and stable in deionized water for 1 month with good dispersion. However, the MWCNTs of the present invention precipitated after 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com