Combined electric flocculation defluorination process and uses thereof

An electro-flocculation and process technology, applied in the field of combined electro-flocculation defluorination process, can solve the problem of no combined electro-flocculation de-fluorination process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

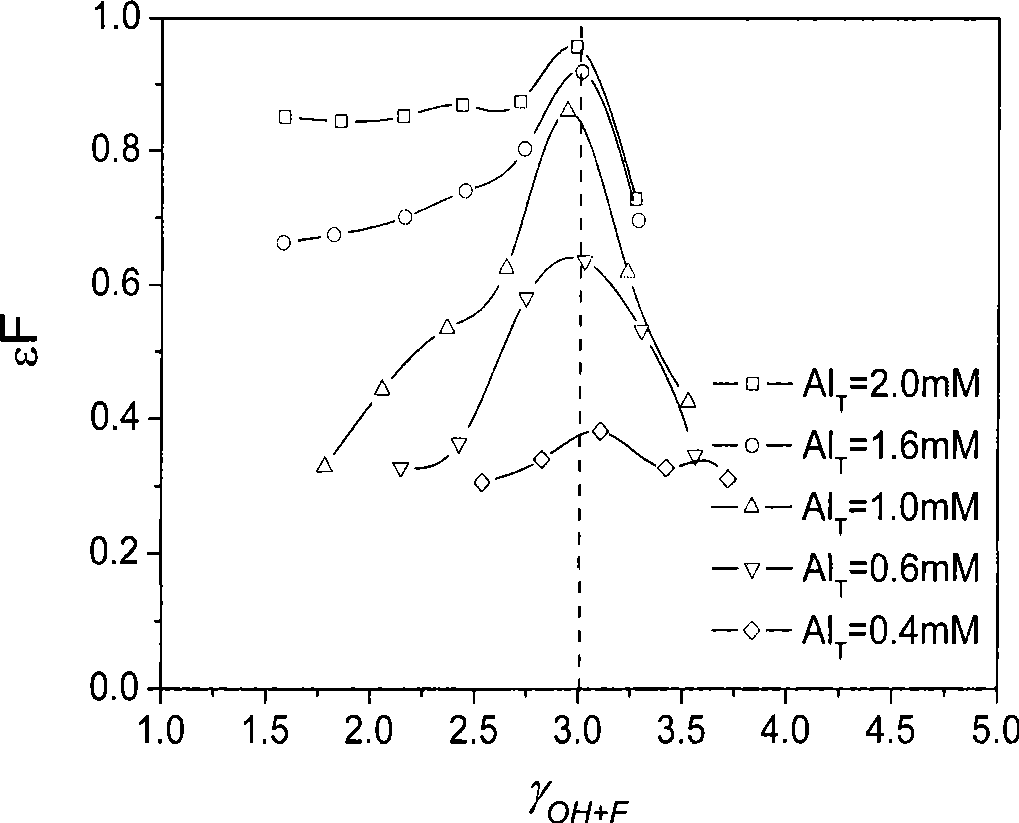

[0038] The experimental water was artificially prepared: 2.0mM NaCl and an appropriate amount of NaF were added to deionized water so that the initial fluoride ion content was 10mg / L. An aluminum plate (99.999% pure) is used as the anode, and a copper plate is used as the cathode. The area of the electrode is 90mm×60mm, and the distance between the plates is 10mm. The experimental water was 300mL, and the electrolysis time was 10min. The research shows that the fluoride removal rate varies with γ Alkalinity+F The change. The experimental results show that for each Al 3+ dosage, when γ Alkalinity+F (In this example, the distribution water contains only OH - Alkalinity, so γ Alkalinity+F = γ OH+F ) close to 3.0, combined electrocoagulation can achieve the highest fluorine removal efficiency. For specific experimental data, see figure 1 .

Embodiment 2

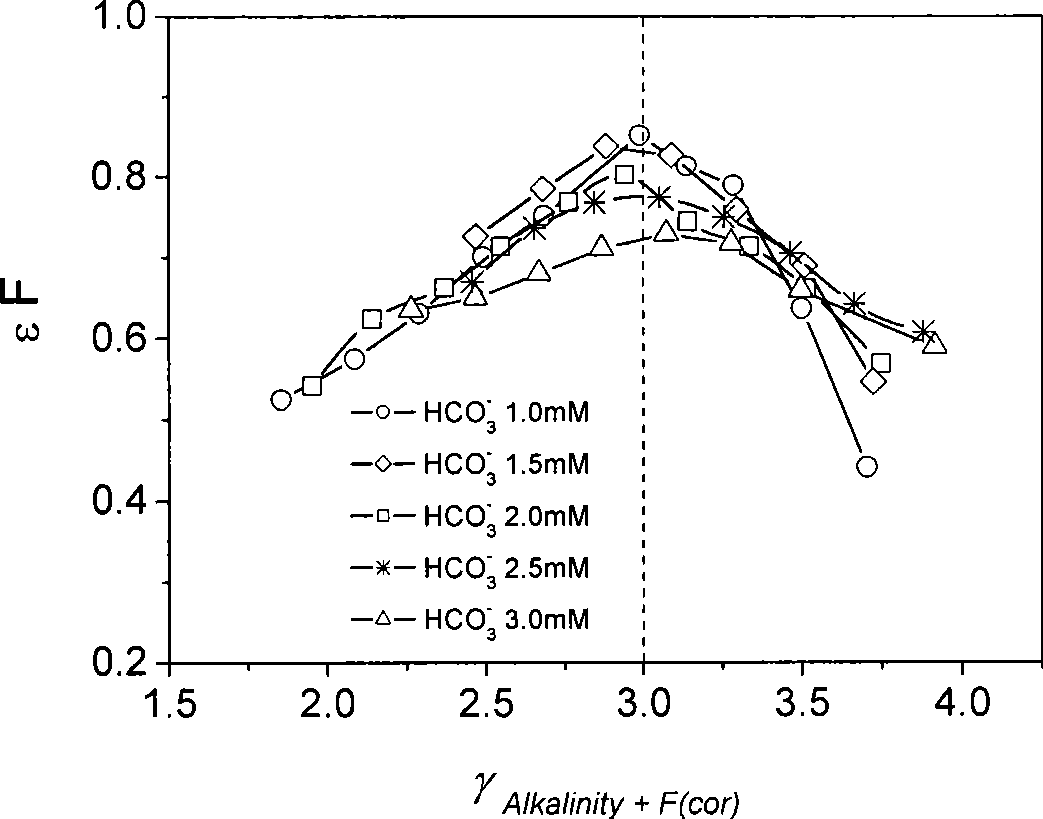

[0039] Example 2: Verifying the presence of HCO in raw water 3 - Alkalinity, by HCO 3 - The concentration of γ is corrected to control γ Alkalinity+F =3.0

[0040] Make the combined electrocoagulation achieve the highest fluoride removal rate (experimentally obtained HCO 3 - The correction factor for alkalinity is 0.6).

[0041] The experimental water was artificially prepared: 2.0mM NaCl and an appropriate amount of NaF were added to deionized water so that the initial fluoride ion content was 10mg / L. An aluminum plate (99.999% pure) is used as the anode, and a copper plate is used as the cathode. The area of the electrodes is 90mm×60mm, and the distance between the plates is 10mm. The experimental water was 300mL, and the electrolysis time was 10min. The total aluminum concentration is 1.2mM / L, the study HCO 3 - The fluorine removal rate when the concentration is 1.0mM / L, 1.5mM / L, 2.0mM / L, 2.5mM / L, 3.0mM / L respectively. Initial HCO 3 - Concentration in the ra...

Embodiment 3

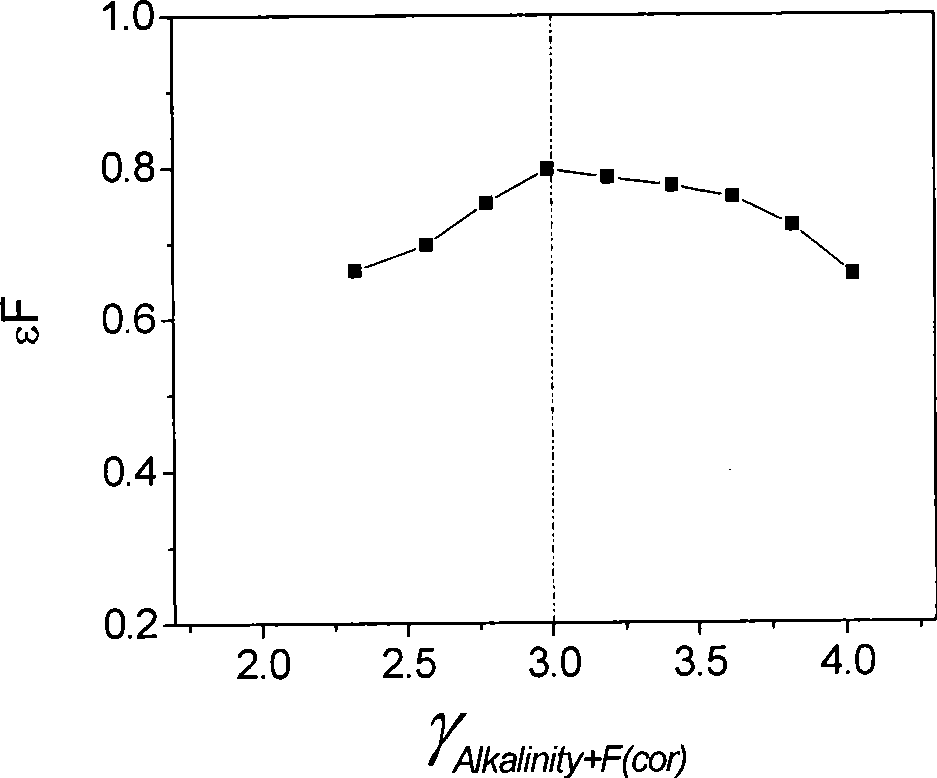

[0042] Embodiment 3: do experimental verification with actual groundwater, in HCO 3 - After correcting the concentration, the fluoride removal rate is at γ Alkalinity+F =3.0

[0043] obtain the maximum value.

[0044] The raw water was taken from the groundwater of Peking University (pH=7.95). By potentiometric titration, the alkalinity type was bicarbonate type, and the initial HCO 3 - The concentration is 2.362mM. After α correction, the design of the combined electrocoagulation defluorination experiment was carried out.

[0045] An aluminum plate (99.999% pure) is used as the anode, and a copper plate is used as the cathode. The area of the electrode is 90mm×60mm, and the distance between the plates is 10mm. The experimental water was 300mL, and the electrolysis time was 10min. in total Al 3+ When the dosage is 1.2mM / L, according to different γ Alkalinity+F value to calculate the AlCl that should be added 3 And the current intensity that should be maintained du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com