Waste ceramic produced environment friendly filter water stone n. and method for producing the same

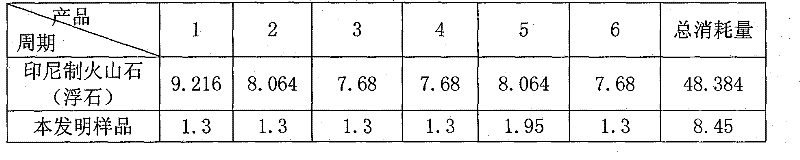

A technology for waste ceramics and washing stones, applied in the field of washing stones, to achieve the effects of low production costs, reduced imports, and improved comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be described in further detail below in conjunction with specific embodiments:

[0026] The main raw material of the washing stone disclosed by the present invention is ceramic waste material. In the ceramic production and construction industry, there are many such waste materials, and their stacking and digestion have always been a headache for the environment. According to statistics, there are more than Hundreds of ceramic production factories produce about 5,000 tons of ceramic waste each year. Today, when our country attaches great importance to environmental protection and the full utilization of resources,

[0027] How to recycle ceramic waste has become an urgent and urgent issue. But the present invention can completely solve this problem and turn waste into wealth.

[0028] According to the weight ratio, the washing stone disclosed by the present invention includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com