Method for extracting admantadine

An amantadine and extraction method technology, which is applied in the extraction field of organic compounds, can solve the problems of large energy consumption, low product quality, low yield and the like, and achieves the reduction of energy consumption, production cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

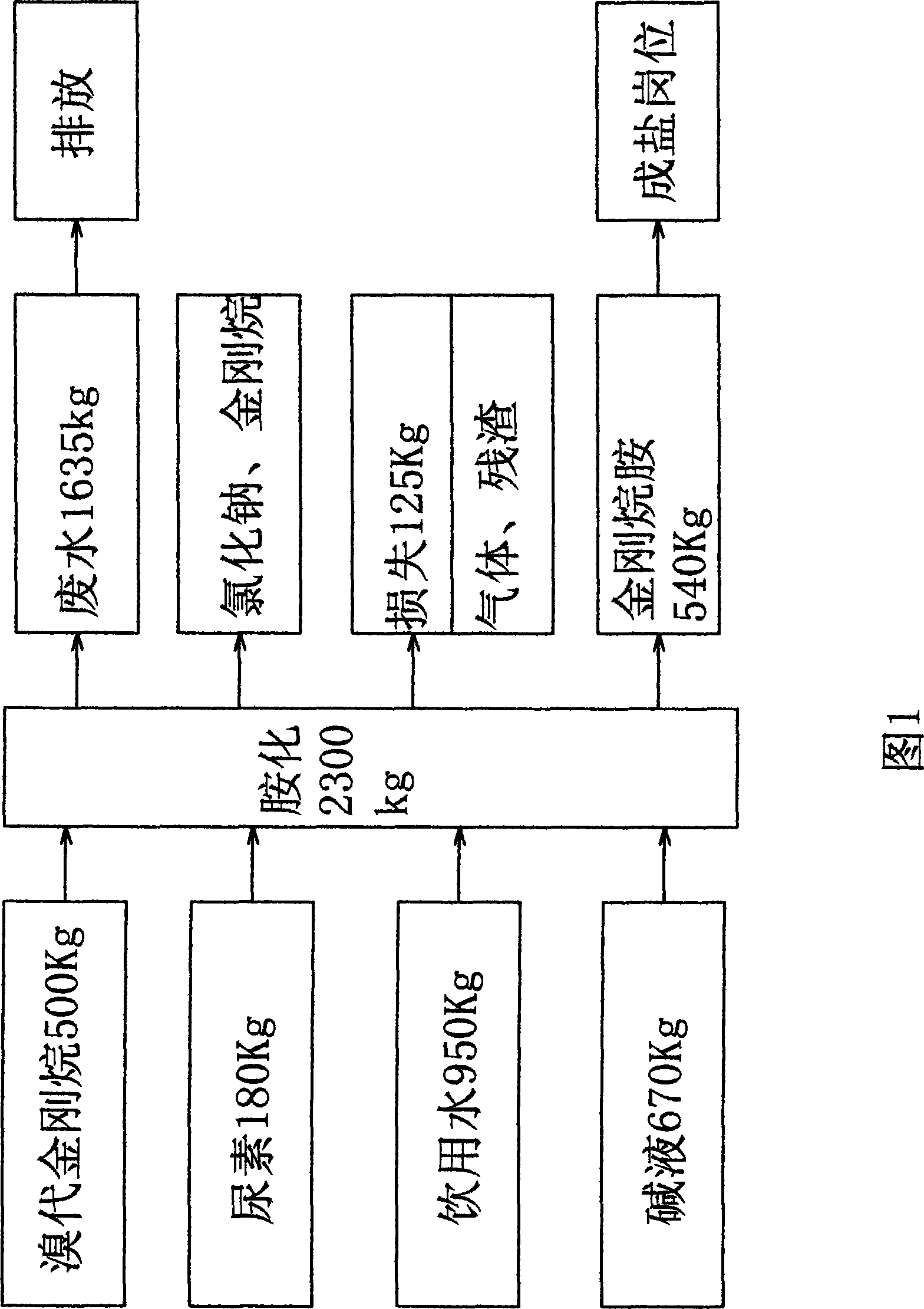

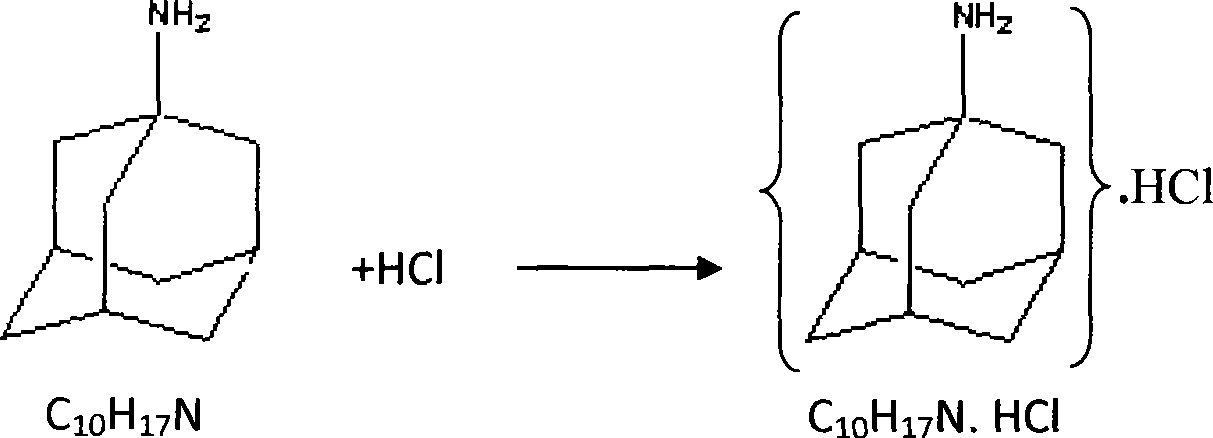

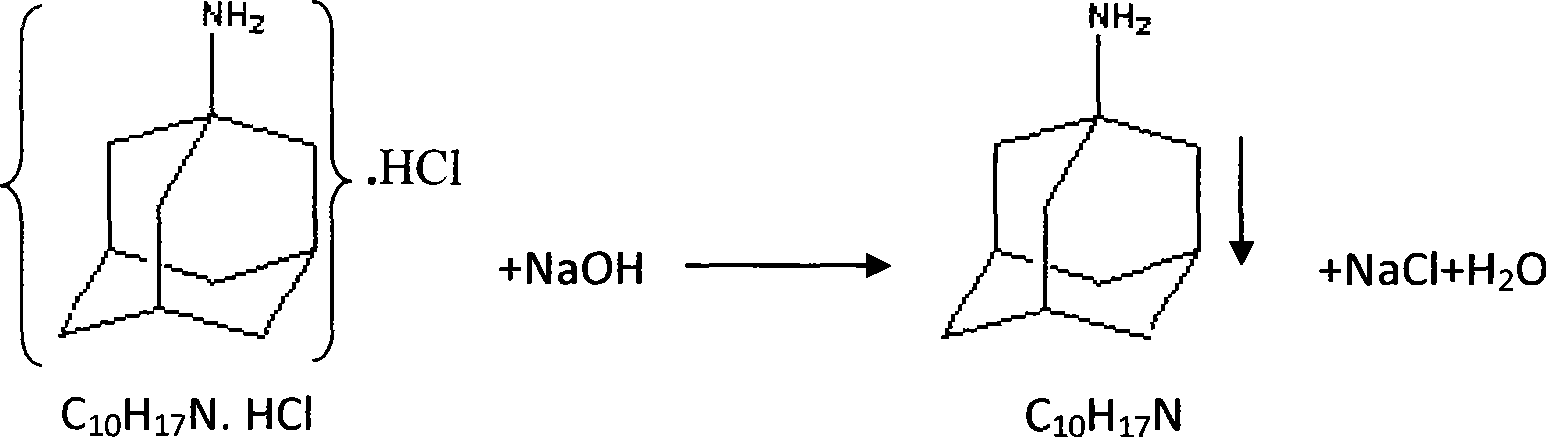

[0023] Add 500Kg of bromoadamantane and 180Kg of urea into the reaction kettle for amination reaction to generate amantadine containing impurities and insoluble in water. When the temperature drops to 100°C-120°C, add 950Kg of drinking water to fully Stir to separate the amantadine and the impurities bonded together, then add concentrated hydrochloric acid until the solution pH=1, the concentrated hydrochloric acid and amantadine react to generate amantadine hydrochloride C10H17N.HCl aqueous solution that can be dissolved in water, and the After amantadine hydrochloride C10H17N.HCl aqueous solution is filtered to remove water-insoluble impurities, sodium hydroxide solution is added to the solution until the solution PH=14, amantadine hydrochloride and sodium hydroxide react to form water-insoluble adamantine again Alkylamine, just filter out amantadine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com