Process for producing mold-inhibiting pigment plaster

A technology of pigment paste and pigment paste meter, which is applied in the directions of pigment slurry, dyeing method, textile and paper making, etc., can solve the problems of easy decomposition, poor heat resistance and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

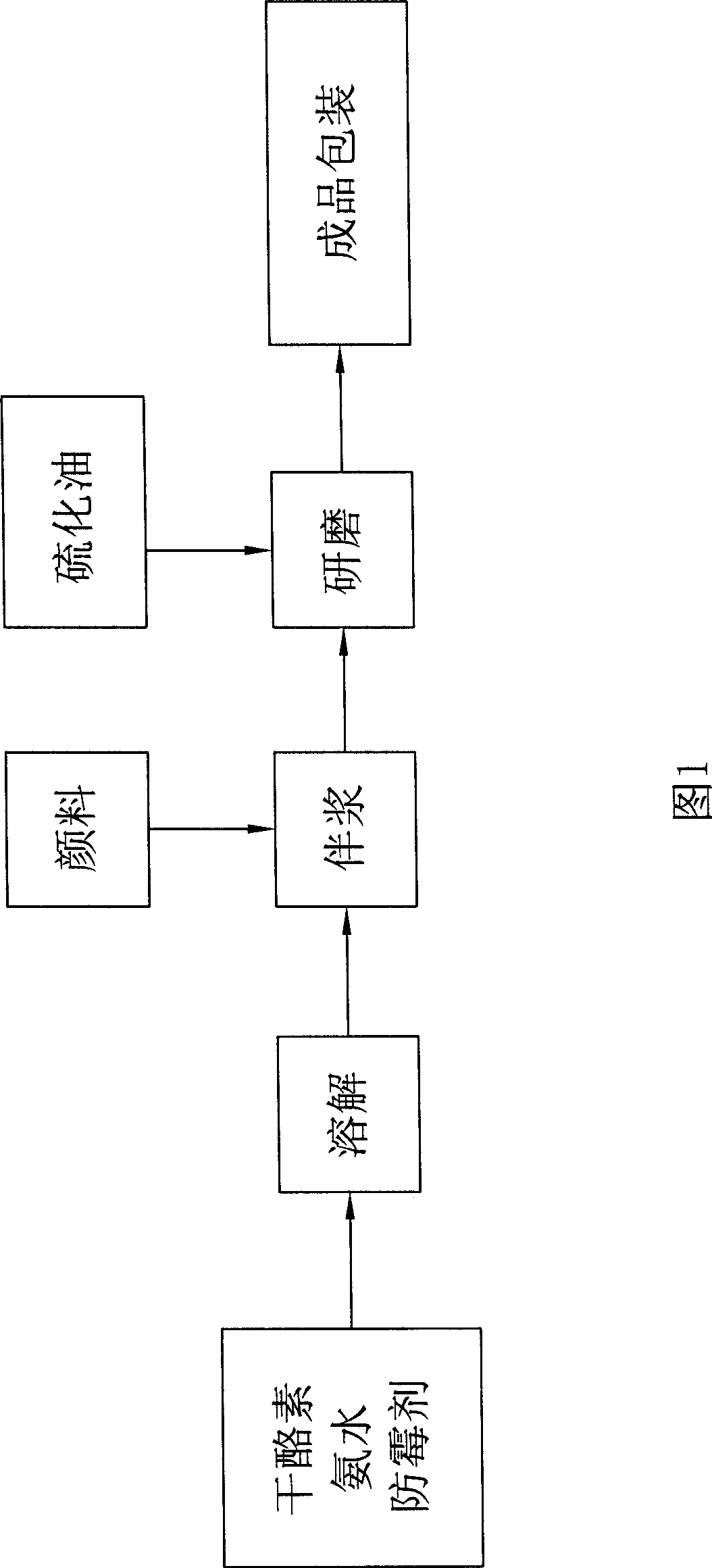

Image

Examples

Embodiment 1

[0047] The first step is to prepare compound antifungal agent:

[0048] 1) Pretreatment of cation exchange resin

[0049] Put the 732 type cation exchange resin in the ion exchange column, convert it to H+ type with 5% hydrochloric acid and wash away the excess hydrochloric acid.

[0050] 2) Loading of metal ions on cation exchange resin

[0051] Use 0.25mol / L CuSO4 solution to flow through the + The ion exchange column of the type resin, so that the ion exchange reaction occurs between the resin and the solution, and the resin is converted from H + type conversion to Cu 2+ type, wash off excess Cu 2+ ion.

[0052] 3) Loading of metal ions on the montmorillonite carrier

[0053] The raw material sodium-based montmorillonite and water were made into a soil slurry at a ratio of 1:50, stirred by an electric motor for 24 hours, left to stand overnight, and set aside.

[0054] Take 20L of the upper layer of montmorillonite slurry and add it to a 50L container. Take 2L Cu 2...

Embodiment 2

[0071] The first step is to prepare composite antifungal agent

[0072] 1) Pretreatment of cation exchange resin

[0073] The 732-type cation-exchange resin was packed in an ion-exchange column, converted to H+ type with 6% hydrochloric acid and washed away excess hydrochloric acid.

[0074] 2) Loading of metal ions on cation exchange resin

[0075] Use 0.25mol / L CuSO4 solution to flow through the + The ion exchange column of the type resin, so that the ion exchange reaction occurs between the resin and the solution, and the resin is converted from H + type conversion to Cu 2+ type, wash off excess Cu 2+ ion.

[0076] 3) Loading of metal ions on the montmorillonite carrier

[0077] The raw material sodium-based montmorillonite and water were made into a soil slurry at a ratio of 1:100, stirred by an electric motor for 24 hours, left to stand overnight, and set aside.

[0078] Take 20L of the upper layer of montmorillonite slurry and add it to a 50L container. Take 2L C...

Embodiment 3

[0095] The first step is to prepare composite antifungal agent

[0096] 1) Pretreatment of cation exchange resin

[0097] The 732-type cation-exchange resin was packed in an ion-exchange column, converted to H+ type with 7% hydrochloric acid and washed away excess hydrochloric acid.

[0098] 2) Loading of metal ions on cation exchange resin

[0099] Use 0.25mol / L CuSO4 solution to flow through the + The ion exchange column of the type resin, so that the ion exchange reaction occurs between the resin and the solution, and the resin is converted from H + type conversion to Cu 2+ type, wash off excess Cu 2+ ion.

[0100] 3) Loading of metal ions on the montmorillonite carrier

[0101] The raw material sodium-based montmorillonite and water were prepared into a soil slurry at a ratio of 1:200, stirred by an electric motor for 24 hours, left to stand overnight, and set aside.

[0102] Take 20L of the upper layer of montmorillonite slurry and add it to a 50L container. Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com