Test method and apparatus for rheological behavior of polymer composite material

A technology for composite materials and rheological properties, applied in the field of testing methods and devices for rheological properties of polymer composite materials based on multifunctional and all-electric methods, can solve the problem of not realizing the integrated design of polymer composite materials and the inability to accurately control polymers Composite material rheological test process, wide material adaptability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

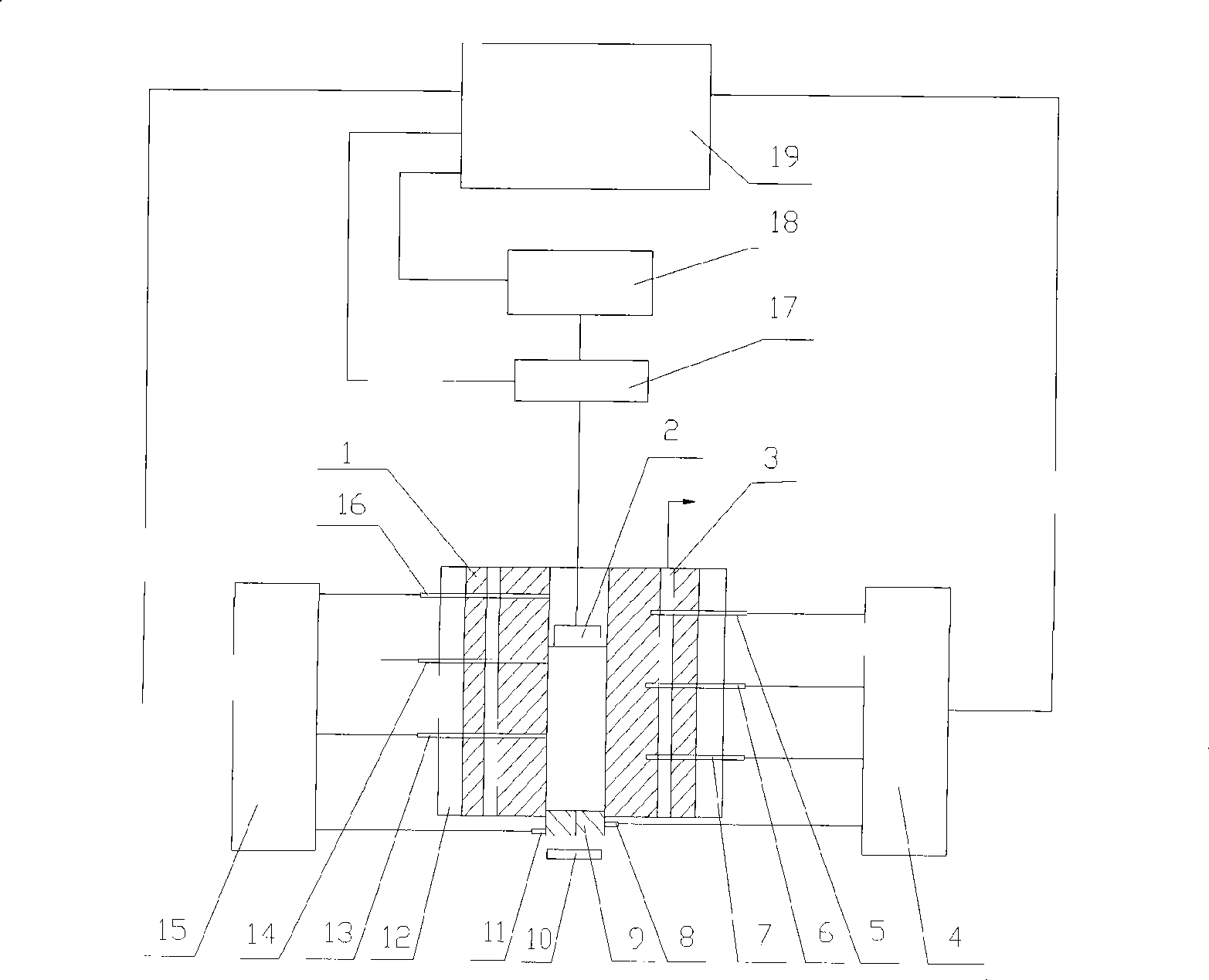

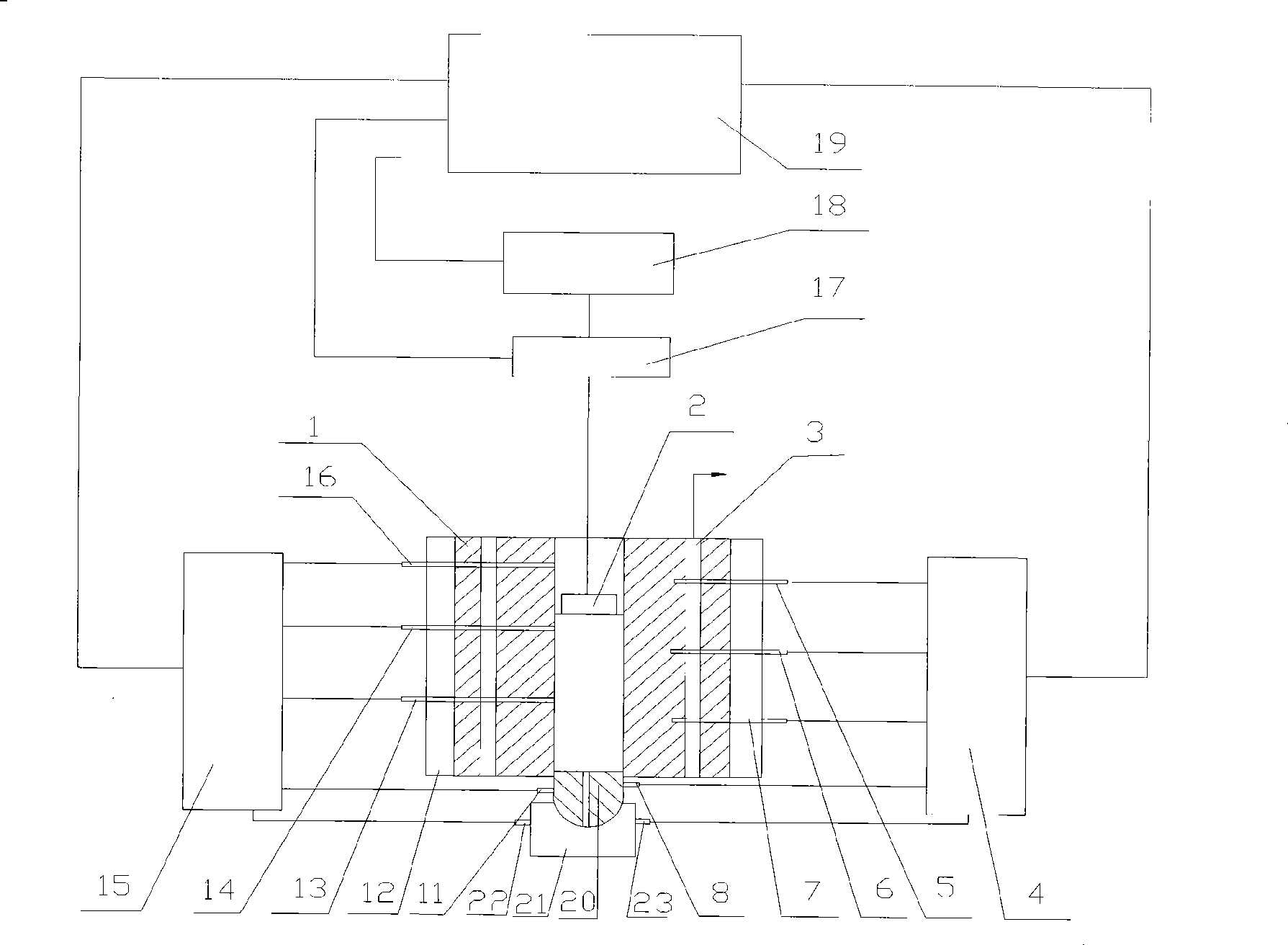

[0034] (1) choose figure 1 Extrusion rheological test device shown in the figure; (2) Weigh 50 grams of LDPE pellets and add them into the barrel; (3) Start the heating system to heat the barrel, and the temperatures of the three sections of the barrel are 180°C, 190°C, 190°C; (4) After 20 minutes of heat preservation, start the vibrator and the servo drive system to make the plunger rod move downward at a constant speed while vibrating. Set the vibration frequency to 10Hz and the amplitude to 0.2mm to make the plunger rod The vibration waveform is sinusoidal vibration; (5) Turn on the data acquisition system to collect signals such as temperature, pressure, displacement, speed, vibration parameters, etc.; (6) Replace the dies with different length-to-diameter ratios, and repeat steps (2) to (5) (7) Data post-processing to obtain data such as apparent viscosity and normal stress difference.

Embodiment 2

[0036] Change the vibration frequency and the amplitude in embodiment 1, all the other are the same;

Embodiment 3

[0038] The frequency of vibration and the amplitude in embodiment 1 are set to zero, and all the other are the same;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com