Test method used for detecting coking coal

A test method and technology of coking coal, which is applied in the direction of fuel oil testing and material inspection products, to achieve the effects of low energy consumption, prevention of excessive moisture, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Main equipment and requirements:

[0032] Colloidal layer index tester: commonly used coal quality testing equipment.

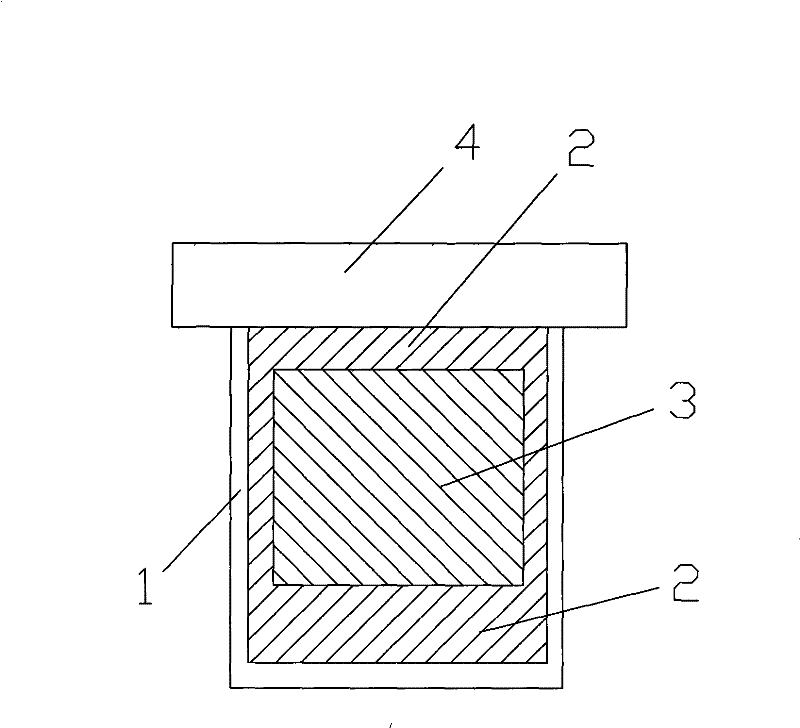

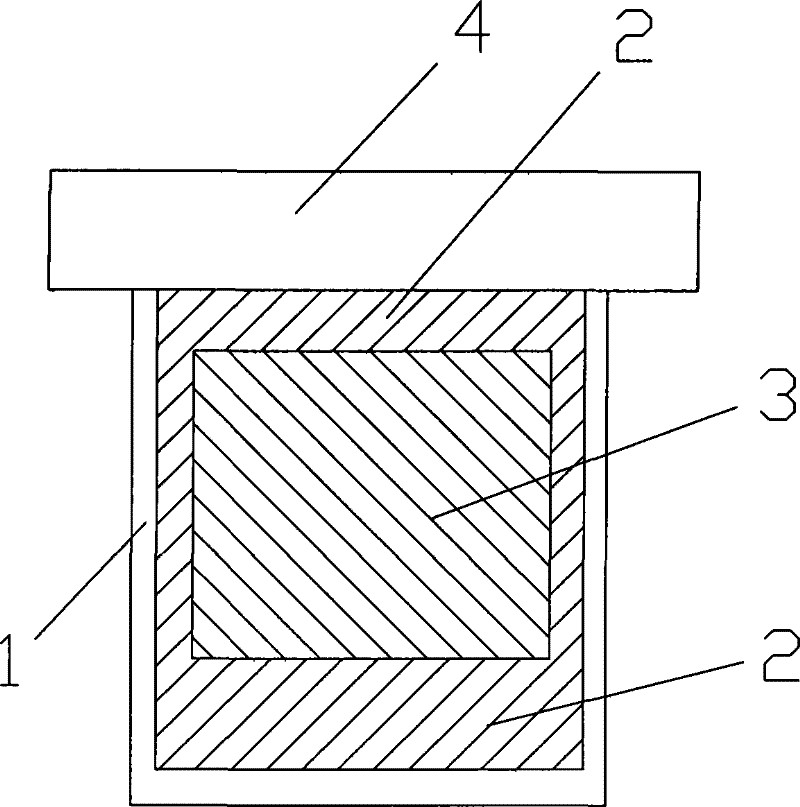

[0033] Corundum crucible: inner diameter 80mm; height not less than 40mm.

[0034] Muffle furnace: the maximum constant temperature is not lower than 1200°C.

[0035] The test method has the following steps:

[0036] (1), coal is burned into the step of semi-coke coke cake with colloidal layer index measuring instrument;

[0037] Within 30 minutes, heat up from room temperature to 250°C at a heating rate of about 8°C / min, and then uniformly heat up to 730°C at a heating rate of 3°C / min. The difference should not exceed 5°C, and the difference should not exceed 10°C at other times. Glial changes during recording.

[0038] (2), the step of detecting semi-coke coke cake;

[0039] Visually inspect the appearance of the semi-coke coke cake, use a ruler to measure the surface cracks and edges, and record the test data.

[0040] (3), burn semi-coke cok...

Embodiment 2

[0047] Main equipment and requirements are the same as embodiment 1.

[0048] The test method has the following steps:

[0049] (1), coal is burned into the step of semi-coke coke cake with colloidal layer measuring instrument;

[0050] (2), the step of detecting semi-coke coke cake;

[0051] (3), burn semi-coke coke cake into coke step with muffle furnace, specifically:

[0052] (3.1), take out the semi-coke coke cake from the coal cup after the colloidal layer measurement test; spread a 3-5cm thick inert material on the bottom of the corundum crucible—corundum sand (also can be other high-temperature resistant non-melting materials); Put the semi-coke coke cake into the corundum crucible, cover the semi-coke coke cake with coke powder and fill the corundum crucible, the thickness of the semi-coke coke cake covered with coke powder is 1-2cm.

[0053] (3.2), put the corundum crucible into the muffle furnace, close the muffle furnace door, isolate the air as much as possible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com