Semiconductor package and manufacturing method thereof

A packaging and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of easy delamination of terminals and packaging colloids, poor bonding force of packaging colloids, etc., to reduce Delamination problem, avoid process inconvenience, avoid the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

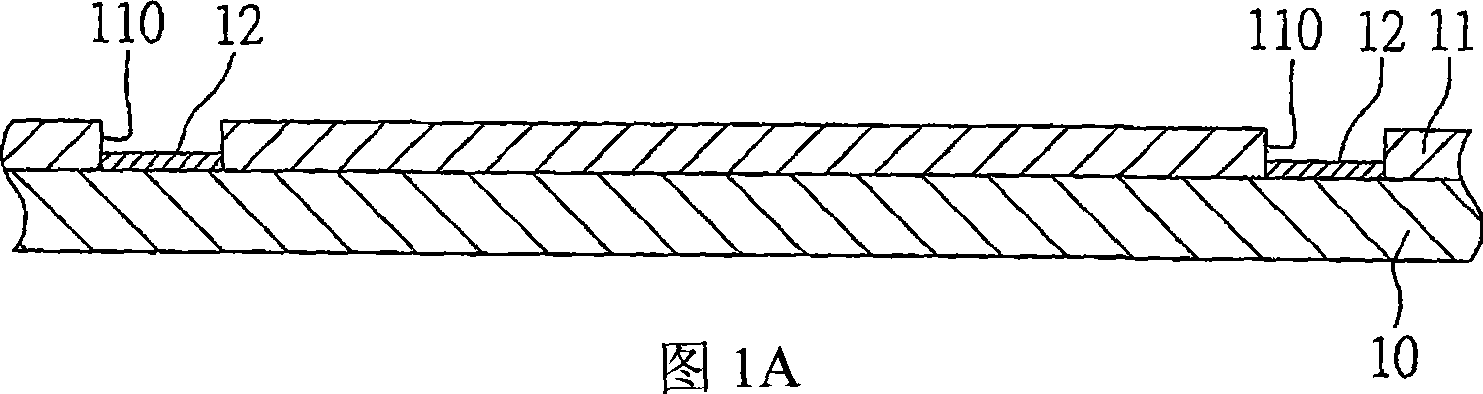

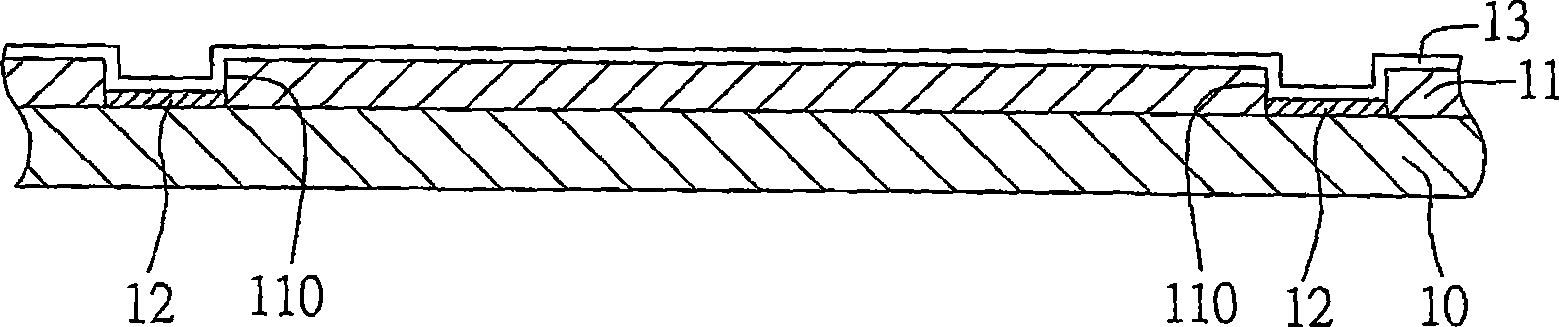

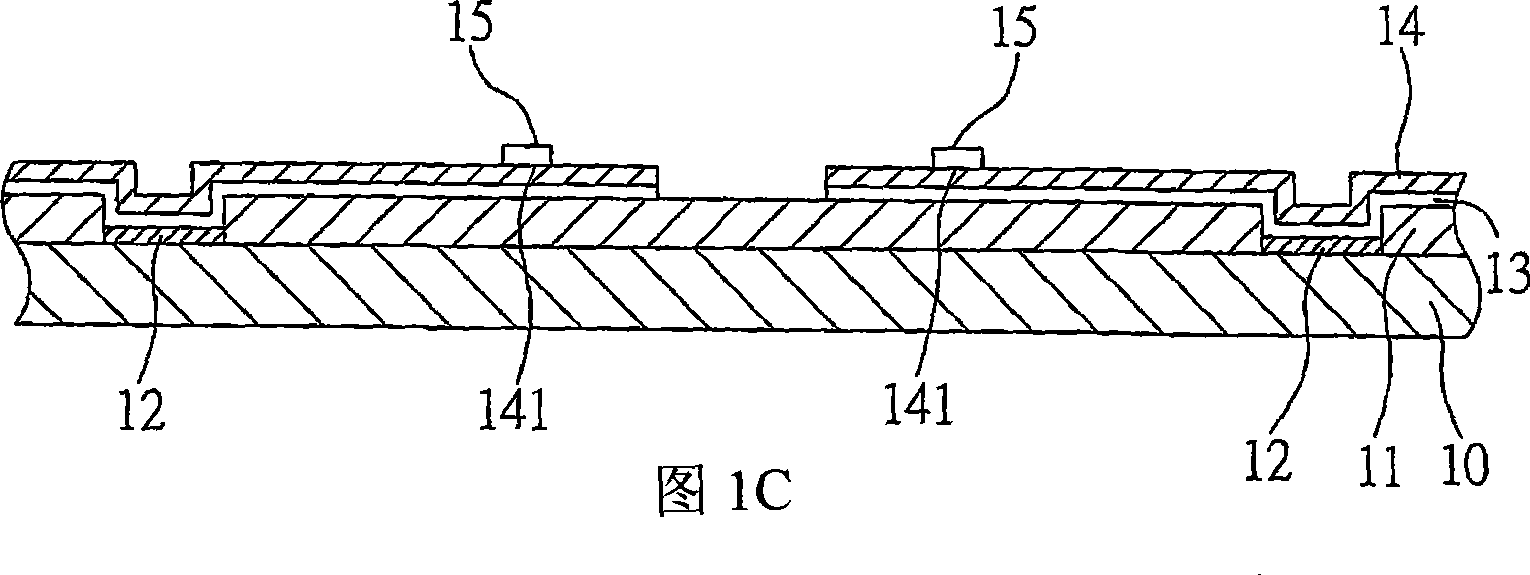

[0077] see Figure 2A FIG. 2H is a schematic cross-sectional view of the first embodiment of the semiconductor package and its manufacturing method of the present invention.

[0078] Such as Figure 2A As shown, first, a metal carrier (Carrier) 20 such as a copper plate (Cu Plate) is prepared, and a first resistance layer 21 is laid on one surface of the metal carrier 20, and the first resistance layer 21 is, for example, a photoresist layer (photo-resist), etc., and through exposure and development, the first resist layer 21 is formed with a through opening 210 that exposes a portion of the metal carrier 20 .

[0079] Then, a conductive metal layer 22 is formed in the first resistive layer opening 210, wherein the conductive metal layer 22 includes a die pad 221 corresponding to the position of the chip and an electrical connection terminal ( terminal) 222. The material of the conductive metal layer 22 is, for example, gold / nickel / copper (Au / Ni / Cu), nickel / gold (Ni / Au), go...

no. 2 example

[0092] Please refer to FIG. 3A to FIG. 3C , which are cross-sectional views of a second embodiment of the semiconductor package and its manufacturing method of the present invention. The semiconductor package and its manufacturing method of this embodiment are substantially the same as those of the foregoing embodiments, the main difference is that before forming the conductive metal layer, a plating layer of the same material as the metal carrier can be formed in the opening of the first resistance layer, so as to facilitate removal. When the metal carrier is used, the plating layer is removed at the same time, so that the conductive metal layer is recessed in the dielectric layer for connecting conductive elements.

[0093] As shown in FIG. 3A , a first resistive layer 31 is laid on a metal carrier 30 (for example, a copper plate), and a plurality of through openings 310 are opened at predetermined positions of the first resistive layer 31 to expose the metal carrier. 30 , t...

no. 3 example

[0097] Please refer to FIG. 4A and FIG. 4B , which are cross-sectional views of a third embodiment of the semiconductor package and its manufacturing method of the present invention.

[0098] The semiconductor package and its manufacturing method of this embodiment are substantially the same as those of the previous embodiments, the main difference is that the material of the conductive metal layer 42 is selected to be the same as that of the metal carrier 40, so that when the metal carrier 40 is removed by etching, Simultaneously etch part of the conductive metal layer 42, and control the etching amount of the conductive metal layer 42 (the depth of etching is about 10 microns), so that the conductive metal layer 42 is recessed in the dielectric layer 43, so that the conductive element 480 is effective fixed on the conductive metal layer 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com