Method and apparatus for casting zinc-base alloy ingot

A casting method and technology for alloy ingots, which are applied in the field of casting methods and devices for zinc-based alloy ingots, and can solve problems that affect the surface quality of zinc-based alloy ingots, products that do not meet physical specification inspection standards, and dents formed in zinc-based alloy ingots. , to achieve the effect of good surface quality, good cooling effect and avoiding the formation of dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for casting zinc-based alloy ingots, which is used for casting zinc-based alloy ingots, which is to first pour molten metal into an ingot mold, and then spray cooling water on the surface of the ingot in the solidification process to cool, and the cooling water The flow rate is 20000 g / min.

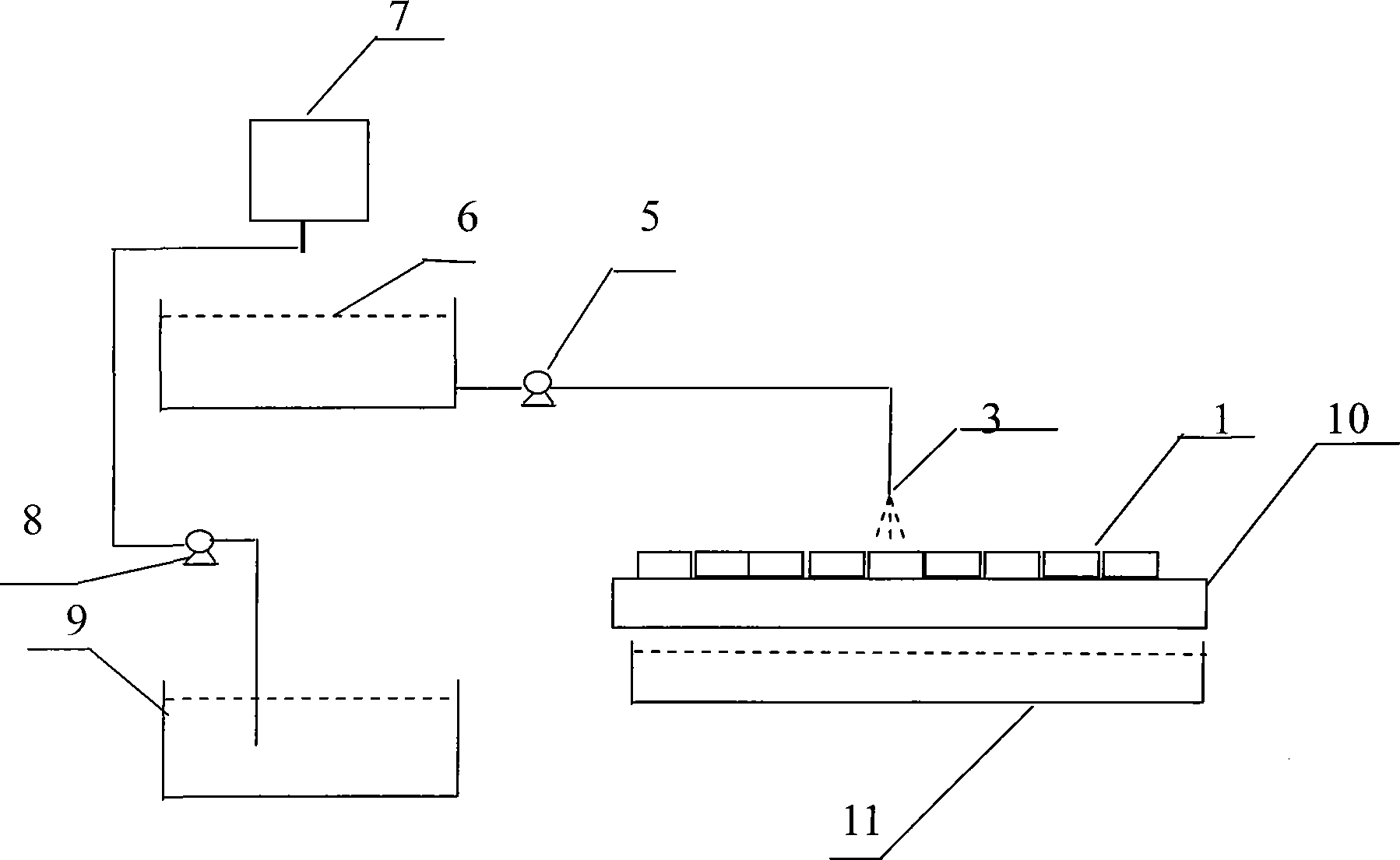

[0025] A casting device for zinc-based alloy ingots, such as figure 1 As shown, it includes a linear molding machine 10. The linear molding machine 10 includes a plurality of linearly moving molds and molds 1 placed in each mold. It also includes spraying cooling water on the ingots in the mold 1 after casting. The spraying device, the spraying device is composed of a spraying head 3, a circulating cooling water pipe 4 and an open water tank 11 for receiving cooling water. The spraying head 3 is fixedly arranged above the linear molding machine 10, and the flow rate of the cooling water sprayed by the spraying head 3 is 20000 g / min, the water tank 11 is placed below the l...

Embodiment 2

[0027] A method for casting zinc-based alloy ingots, which is used for casting zinc-based alloy ingots, which is to first pour molten metal into an ingot mold, and then spray cooling water on the surface of the ingot in the solidification process to cool, and the cooling water The flow rate is 1100 g / min.

[0028] A casting device for zinc-based alloy ingots, such as figure 1 As shown, it includes a linear molding machine 10. The linear molding machine 10 includes a plurality of linearly moving molds and molds 1 placed in each mold. It also includes spraying cooling water on the ingots in the mold 1 after casting. Spraying device, the spraying device is composed of nozzle 3, circulating cooling water pipe 4 and open water tank 11 for receiving cooling water. g / min, the water tank 11 is placed below the linear molding machine 10, the vertical distance between the shower nozzle 3 and the mold is 20 centimeters, the lower surface of the mold is placed in the cooling water in the...

Embodiment 3

[0030] A casting method of a zinc-based alloy ingot, which is first to cast molten metal into an ingot mold, and then spray cooling water on the surface of the ingot in the solidification process for cooling, the cooling water is atomized cooling water, atomized cooling The flow rate of water was 200 g / min.

[0031] A casting device for zinc-based alloy ingots, such as figure 1 As shown, it includes a linear molding machine 10. The linear molding machine 10 includes a plurality of linearly moving molds and molds 1 placed in each mold. It also includes spraying cooling water on the ingots in the mold 1 after casting. The spraying device is composed of a spraying head 3, a circulating cooling water pipe 4 and an open water tank 11 for receiving cooling water. The spraying head 3 is fixed above the linear molding machine 10. The spraying device is an atomizing spraying device. The spraying head 3 For the atomizing nozzle, the flow rate of the atomizing cooling water is 200 g / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com