Preparation of antistatic water solution

An aqueous, antistatic technology, applied in conductive coatings, coatings, etc., can solve problems such as incompatibility, and achieve the effects of low surface resistance, low equipment requirements, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

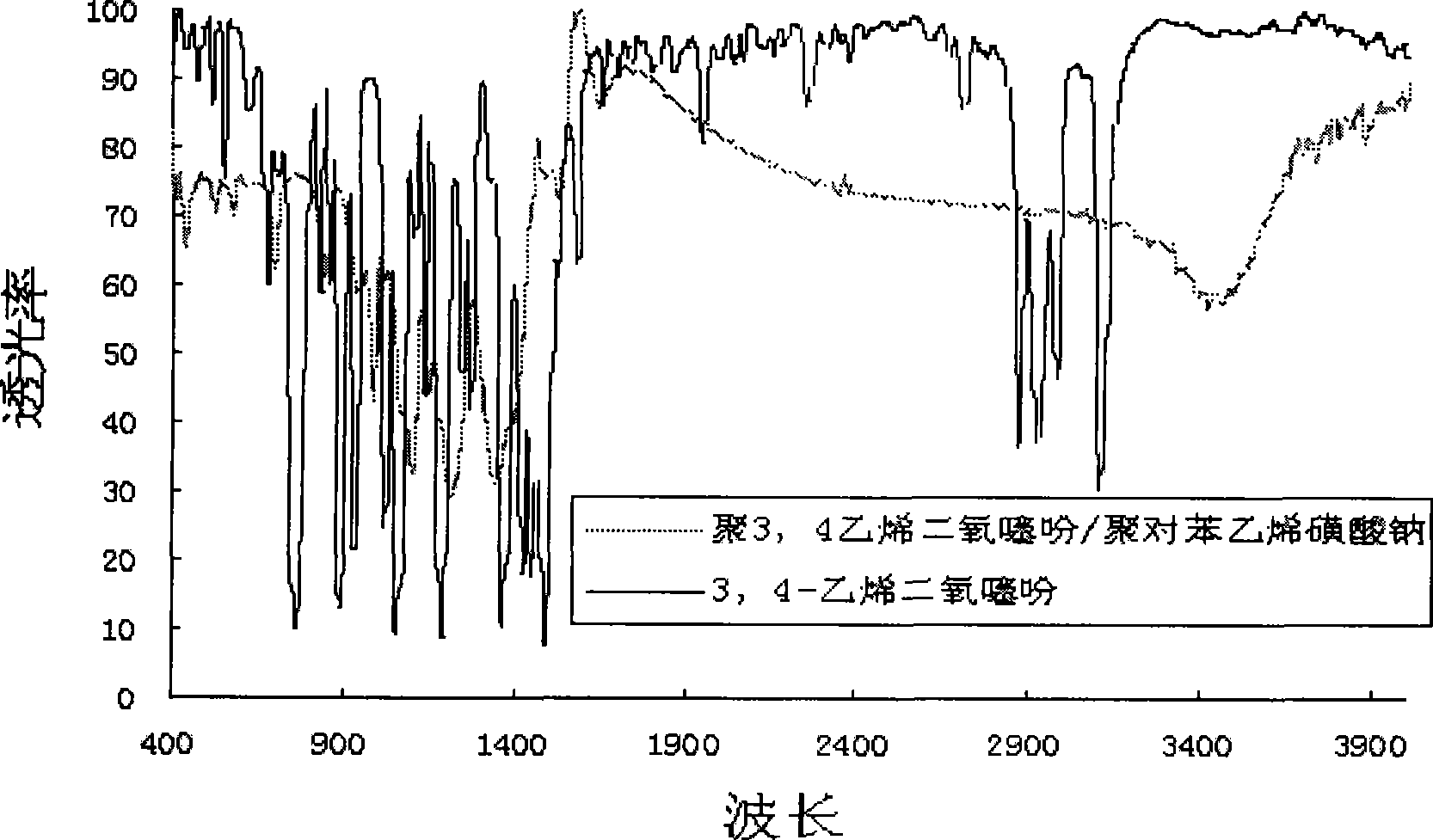

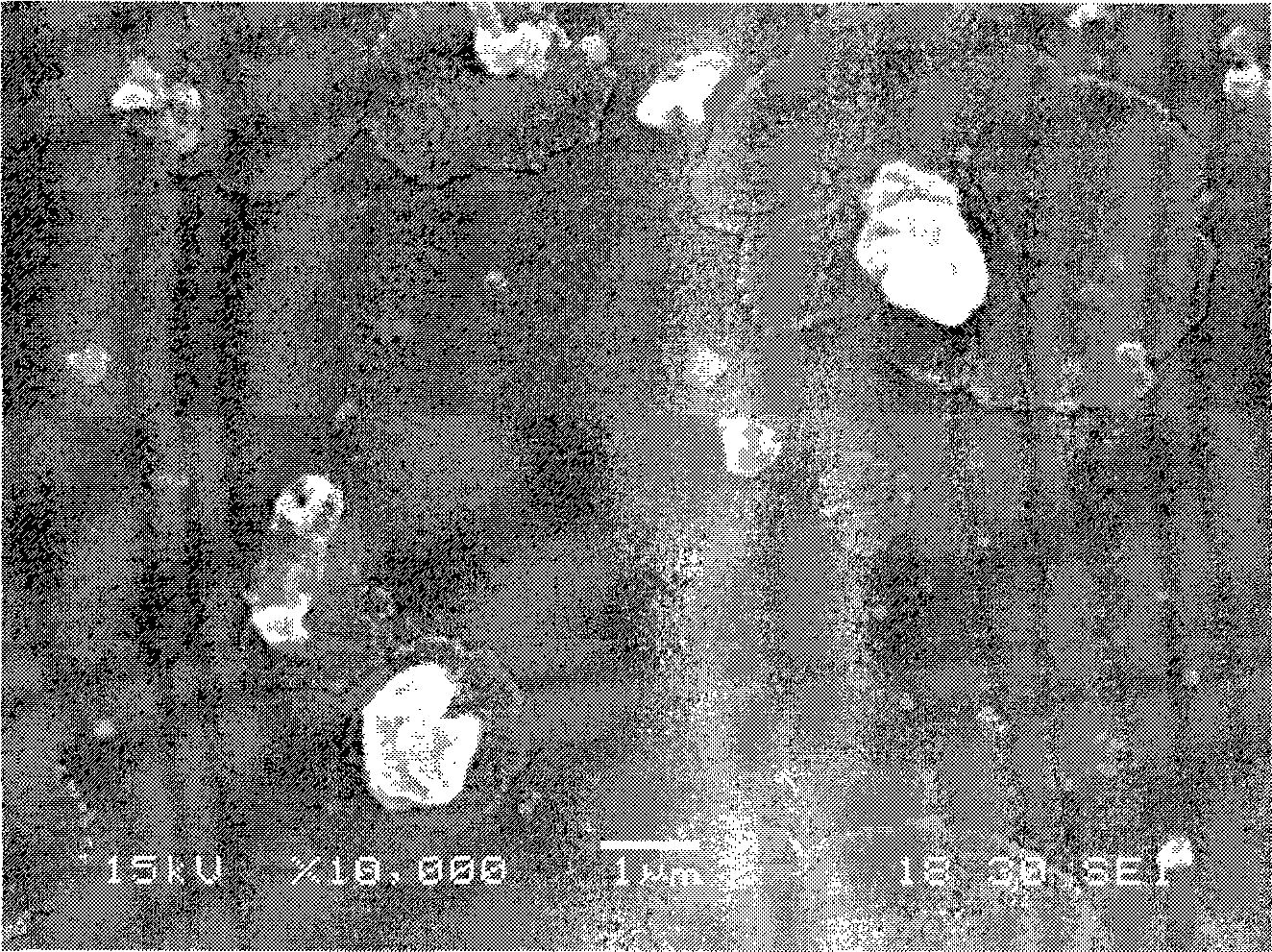

[0025] 1) Preparation of poly 3,4 ethylenedioxythiophene / polystyrene sodium sulfonate aqueous solution

[0026] Preparation method: chemical oxidation polymerization

[0027] Reaction temperature: room temperature (15~30℃)

[0028] Planned weighing: potassium persulfate: sodium polystyrene sulfonate: 3,4-ethylenedioxythiophene = 3:5:1

[0029] Solid content of poly-3,4-ethylenedioxythiophene: 1%-1.5%

[0030] PH control: 1-1.5

[0031] Stirring rate: 800R / min

[0032] Actual weighing: Potassium persulfate: 3.1091g, aqueous solution of sodium polystyrene sulfonate: 22.8200g, 3,4-ethylenedioxythiophene: 1.0186g

[0033] Experimental procedure: use an electronic balance to accurately weigh 22.8200g of polystyrene sodium sulfonate aqueous solution and pour it into a three-necked flask, then accurately weigh 1.0186g of 3,4-ethylenedioxythiophene and accurately transfer it into a three-necked flask, then add 150ml of deionized water, magnetically stirred for 10 minutes, and fin...

Embodiment 2

[0045] 1) Preparation of poly 3,4 ethylenedioxythiophene / polystyrene sodium sulfonate aqueous solution

[0046] Preparation method: chemical oxidation polymerization

[0047] Reaction temperature: room temperature (15~30℃)

[0048] Planned weighing: potassium persulfate: sodium polystyrene sulfonate: 3,4-ethylenedioxythiophene=3:2.5:1 poly-3,4-ethylenedioxythiophene solid content: 1%-1.5%

[0049] PH control: 1-1.5

[0050] Stirring rate: 1200R / min

[0051] Actual weighing: Potassium persulfate: 3.1091g, sodium polystyrene sulfonate aqueous solution: 12.5200g, 3,4-ethylenedioxythiophene: 1.0186g

[0052] Experimental procedure: use an electronic balance to accurately weigh 12.5200g of polystyrene sodium sulfonate aqueous solution and pour it into a three-necked flask, then accurately weigh 1.0186g of 3,4-ethylenedioxythiophene and accurately transfer it into a three-necked flask, then add 150ml of deionized water, magnetically stirred for 10 minutes, and finally accurately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com