Grinding medium containing ceramic particle, preparation and use thereof

A technology of ceramic particles and abrasives, used in abrasives, chemical instruments and methods, manufacturing tools, etc., can solve the problems of easy plastic deformation of the surface, affecting the sharpness of the tool, and reducing the adhesion of the carcass, and achieve the effect of expanding the field of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

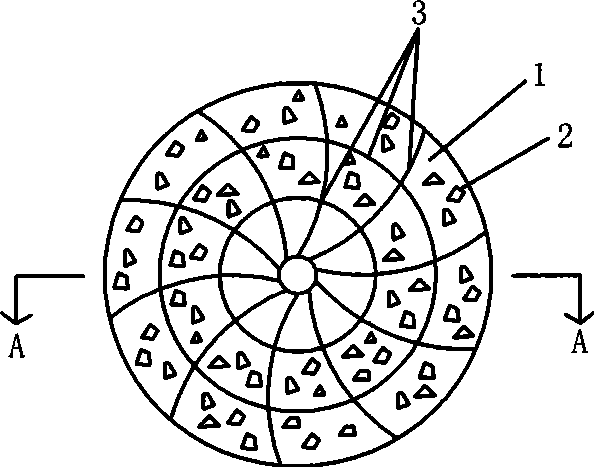

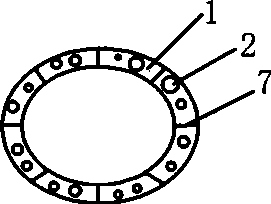

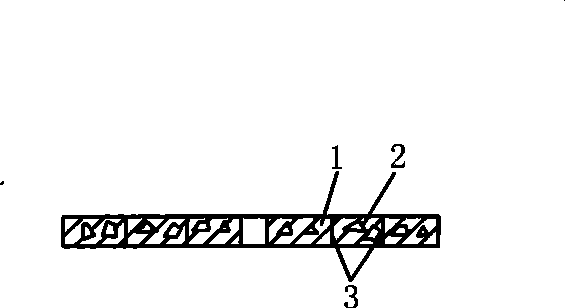

[0045]Commercially available ceramic powder and diamond (superhard material) sintered body are pulverized, and the sintered body component is by mass percent, ceramic powder 20%, diamond 80%, and screening obtains irregular irregular ceramic particles containing 60 mesh diamond ( The particle size is 1-3mm). After uniformly mixing the obtained ceramic particles with the phenolic resin, 60-mesh diamond powder and zinc oxide powder constituting the abrasive bond on a mixer, the abrasive containing ceramic particles of the present invention is obtained. The composition of the obtained abrasive material containing ceramic particles is 20% of ceramic particles, 60% of phenolic resin, 10% of diamond and 10% of zinc oxide powder according to mass percentage. The obtained abrasive containing ceramic particles is packed into a metal mold, and the mold is put into a hot press at a temperature of 200°C for 15 minutes, and then the mold is opened to produce a 60# diamond grinding disc. s...

Embodiment 2

[0047] Similar to Example 1, the difference is that the commercially available ceramic powder and diamond (superhard material) sintered body is composed of 99% ceramic powder and 1% diamond by mass percentage. The components of the obtained abrasive material containing ceramic particles are proportioned by mass percentage as 3% of ceramic particles, 60% of phenolic resin, 10% of diamond, and 27% of zinc oxide powder.

Embodiment 3

[0049] Similar to Example 1, the difference is that the commercially available ceramic powder and diamond (superhard material) sintered body consists of 60% ceramic powder and 40% diamond by mass percentage. The components of the obtained abrasive material containing ceramic particles are proportioned by mass percentage as 90% of ceramic particles, 8% of phenolic resin and 2% of diamond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com