Casting type austenite stainless steel and manufacturing method thereof

A technology of Worth field iron series and manufacturing method, which is applied in the field of cast-type Worth field iron series stainless steel and its manufacturing, can solve the problems of rising nickel cost, large fluctuations in stainless steel prices, and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

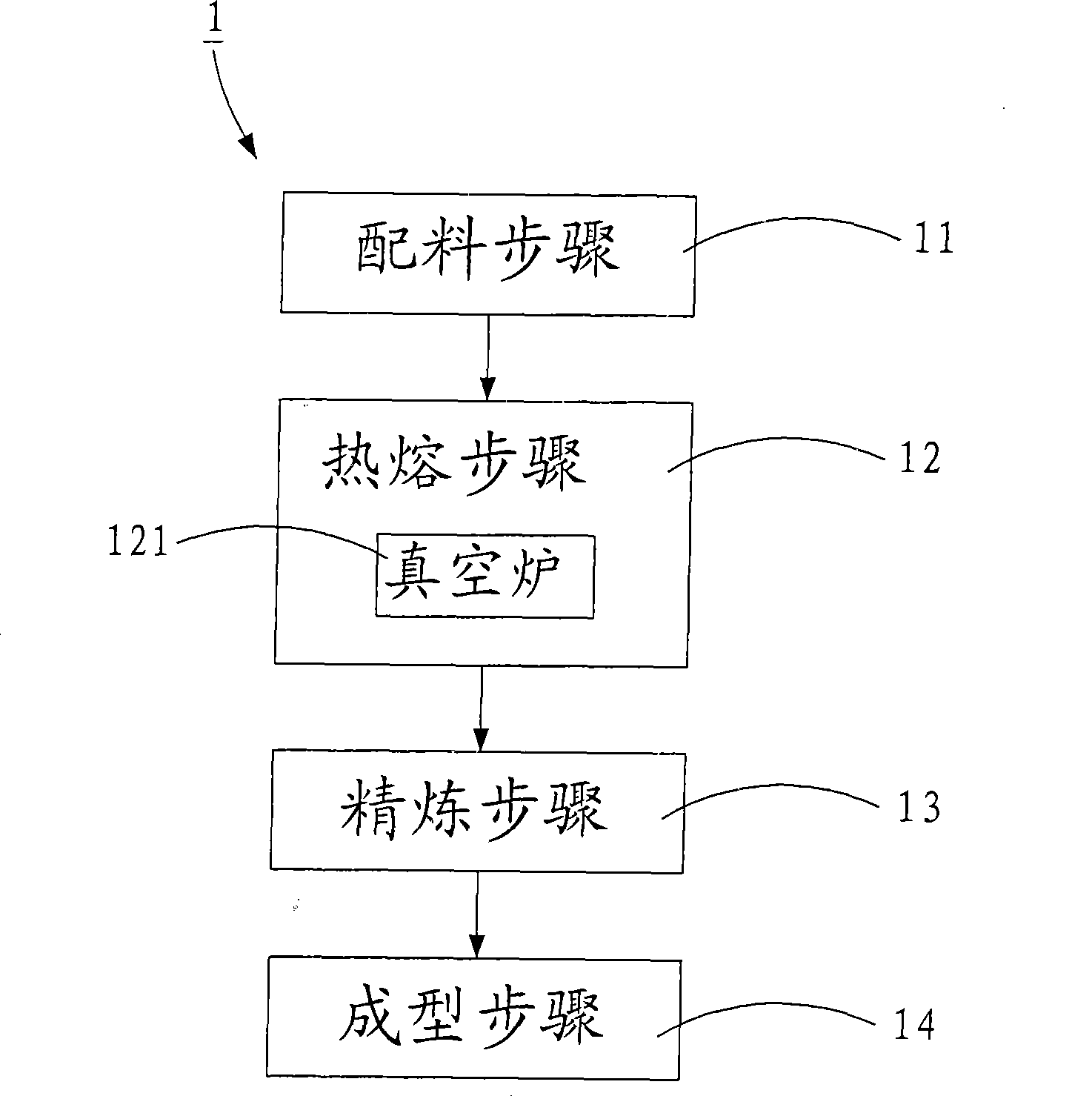

[0037] The foregoing and other technical contents, features and functions of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

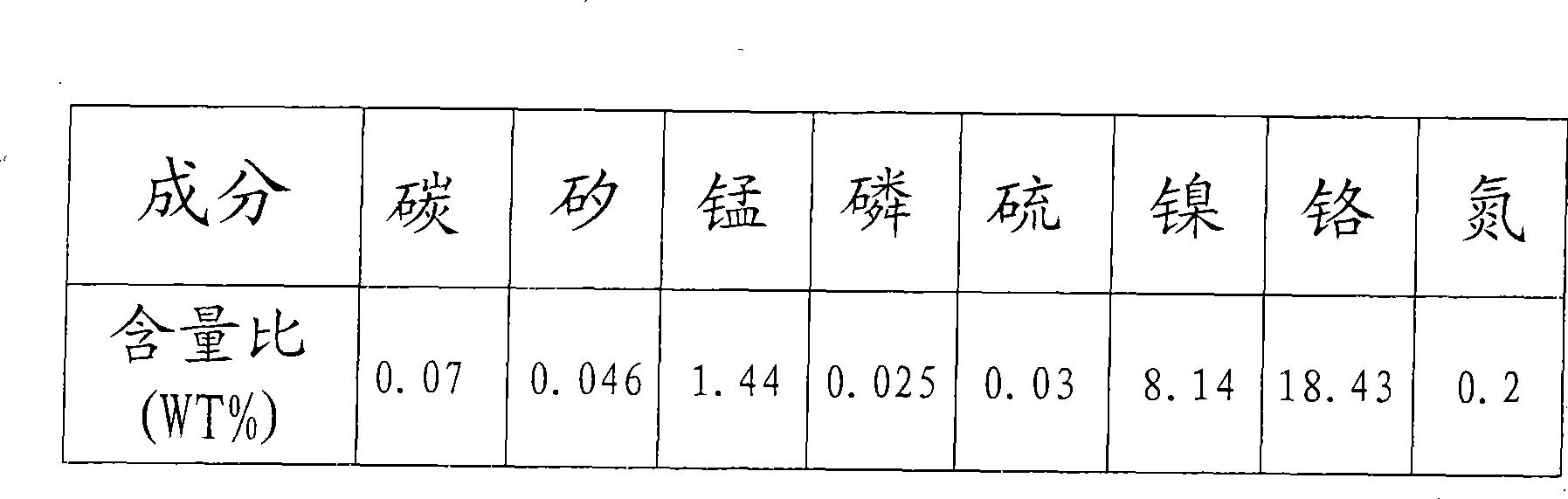

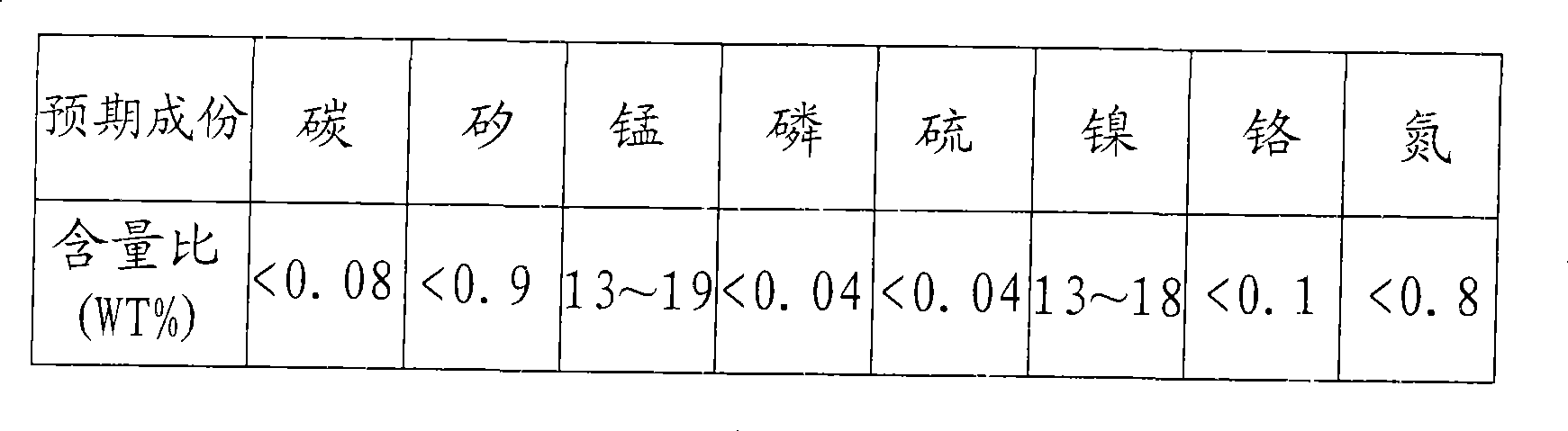

[0038] refer to image 3 , the casting type of the present invention Worth field iron series stainless steel, its composition comprises:

[0039] Carbon element less than 0.08 weight percent (wt%);

[0040] Silicon element less than 0.9 weight percent (wt%);

[0041] Manganese element between 13 and 19 weight percent (wt%);

[0042] Phosphorous element less than 0.04 weight percent (wt%);

[0043] Sulfur element less than 0.04 weight percent (wt%);

[0044] Chromium element between 13 and 18 weight percent (wt%);

[0045] Nickel element less than 0.1 weight percent (wt%);

[0046] Nitrogen element less than 0.8 weight percent (wt%); and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com